Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Arcteq AQ-1000

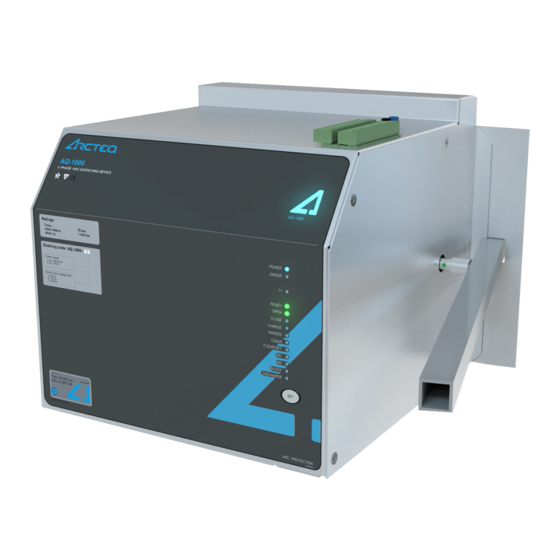

- Page 1 AQ-1000 Arc Quenching Device Instruction manual...

-

Page 2: Table Of Contents

12.1. Preparing AQ-1000 for commissioning tests ........ -

Page 3: Revision History

AQ-1000 Instruction manual Version: 1.04 1. Revision history Revision 1.00 Date 20.06.2016 Changes - The rst revision for AQ-1000 manual Revision 1.01 Date 22.06.2016 Changes - Table of contents corrected Revision 1.02 Date 3.4.2017 Changes - Technical data updated Revision 1.03... - Page 4 Nothing contained in this document shall increase the liability or extend the warranty obligations of the manufacturer Arcteq Relays Ltd. The manufacturer expressly disclaims any and all liability for any damages and/or losses caused due to a failure to comply with the instructions contained herein or caused by persons who do not ful l the aforementioned requirements.

- Page 5 AQ-1000 Instruction manual Version: 1.04 Copyright Copyright © Arcteq Relays Ltd. 2018. All rights reserved. © Arcteq Relays Ltd...

-

Page 6: Safety Precautions

Version: 1.04 2. Safety precautions The AQ-1000 arc quenching device is intended for making a low-impedance short-circuit between all the phases, which is comparable to a bolted short-circuit. Installation shall not be done before the entire system has been veri ed to withstand a bolted short-circuit. This... -

Page 7: Introduction

Version: 1.04 3. Introduction The AQ-1000 is a resettable arc quenching device. The device is used to mitigate the arc flash energy from an arc flash event. When an arc fault occurs, the AQ-1000 creates an low impedance three- phase short-circuit which extinguishes the arc and gives the circuit breaker time to open and completely clear the fault. -

Page 8: Installation

4. Installation NOTE! For the technical instructions related to installation and mounting, please refer to the chapter titled "Technical data". 4.1. Device dimensions Figure. 4.1. - 1. Device dimensions from the front. All dimensions in millimeters. © Arcteq Relays Ltd... - Page 9 AQ-1000 Instruction manual Version: 1.04 Figure. 4.1. - 2. Device dimensions from the left side. All dimensions in millimeters. © Arcteq Relays Ltd...

- Page 10 AQ-1000 Instruction manual Version: 1.04 Figure. 4.1. - 3. Reset handle movement area and space reservation. All dimensions in millimeters. © Arcteq Relays Ltd...

- Page 11 AQ-1000 Instruction manual Version: 1.04 Figure. 4.1. - 4. Mounting dimensions from the bottom side. All dimensions in millimeters. © Arcteq Relays Ltd...

- Page 12 AQ-1000 Instruction manual Version: 1.04 Figure. 4.1. - 5. Busbar joint dimensions form the back side. All dimensions in millimeters. © Arcteq Relays Ltd...

-

Page 13: Mechanical Installation

AQ-1000 Instruction manual Version: 1.04 4.2. Mechanical installation Figure. 4.2. - 6. Installation picture – tray assembly. © Arcteq Relays Ltd... - Page 14 AQ-1000 Instruction manual Version: 1.04 Figure. 4.2. - 7. Installation picture – C-rail assembly. © Arcteq Relays Ltd...

- Page 15 AQ-1000 Instruction manual Version: 1.04 Figure. 4.2. - 8. Installation picture – busbar mounting alternatives. NOTE! For the technical instructions related to installation and mounting, please refer to the chapter titled "Technical data". © Arcteq Relays Ltd...

-

Page 16: Wiring

The device earth (also known as the device ground) is connected to the device chassis. When earthing the AQ-1000 device, you should make sure that the switchgear has adequate earthing. If the device is mechanically installed on a tray, C-rail or some other structure that is properly connected to the switchgear earth, no additional earthing practices are required. -

Page 17: Device States

Maintenance Error is generated when the device has reached the maximum number of trips. A Maintenance Alarm or Error is also generated if the device’s energy capacitor has reached the end of its lifetime. Maintenance Please contact Arcteq technical support for further instructions. © Arcteq Relays Ltd... - Page 18 AQ-1000 Instruction manual Version: 1.04 Figure. 5. - 9. Operating modes Ready and Trip. © Arcteq Relays Ltd...

- Page 19 AQ-1000 Instruction manual Version: 1.04 © Arcteq Relays Ltd...

-

Page 20: Led Indicators

AQ-1000 Instruction manual Version: 1.04 6. LED indicators AQ-1000 has fourteen (14) LED indicators on its front panel for the various operating states. The following table describes them in detail. Table. 6. - 1. LED indicators. LED name Color LED is OFF... -

Page 21: Binary Input Functions

Blocks the trip contact activation during commissioning tests or during any other circumstances where BI4 - Blocking actual tripping must be prevented. function See also Chapter 10 for using Binary Input 4 for testing and commissioning purposes. © Arcteq Relays Ltd... -

Page 22: Relay Functions

The device is unblocked. The quenching contacts will The movement of the quenching contacts is blocked blocked move when the device is tripped. by the blocking function (BI4). Trip contact The device has not tripped. The device has tripped. © Arcteq Relays Ltd... -

Page 23: Set Button

Version: 1.04 9. Set button The AQ-1000 contains a Set button in the front panel which is used for resetting the indicators after a Trip event and to clear resolved error signals. The Set button is pressed for ve (5) seconds when installing ber inputs to the COM ports. -

Page 24: Self-Supervision Functions: Alarms And Errors

This error occurs when one or two ber connections are missing from the ber input COM ports. When installing the Arc Protection System, always ensure that the AQ-1000 device has a connection to the AQ-100 host device. When using a connection from two AQ-100 host devices, make sure that both COM ports are properly installed. - Page 25 When the device has been in use for over ten (10) years, the device generate a maintenance alarm. This does not prevent the device from operating. When this alarm is generated, the AQ-1000 device should be replaced as soon as possible. The user should contact Arcteq technical support for further instructions.

-

Page 26: Accessories And Arc Protection System Devices

AQX060C – Reset handle One per an AQ-1000 device Arc protection system devices The AQ-1000 is an additional part of the Arc Protection System (the AQ-100 series). The following devices are compatible with the Arc Protection System: Medium-voltage series of arc flash relays... -

Page 27: Arc Protection System Testing

When commissioning or testing the device, the commissioning function can be used to verify that the signal transmission to the AQ-1000 device is correct. While in this mode, the device trips normally but the trip counter does not increase. This mode can be entered by connecting the device with AQtivate software through the front USB port. -

Page 28: Testing Individual Arc Sensors

The selected Standard Arc Scheme (SAS) describes which arc protection relay trips the AQ-1000 device and under what conditions the trip occurs. The host relay might not trip the AQ-1000 device with light sensor activation (L>) alone, as it may require a current activation (I>) signal as well. Please refer to your chosen Arc Scheme for more details. -

Page 29: Testing With Arc Sensor Testers

Instruction manual Version: 1.04 In applications that rely solely on sensor activation for tripping the breakers (as well as the AQ-1000 arc quenching device), the arc sensor testers (AST-01 and AST-02) can be used to complete a full test on the arc protection system. However, in devices requiring simultaneous light and current activation, an additional current injection device must be used in order to trip the AQ-100 arc protection relay. - Page 30 Always remove the handle after the device has been reset. If it is not removed, the handle may disengage from its slot as a result of a trip and cause harm or damage. WARNING! Never attach the handle to the device when the device is in the open position. © Arcteq Relays Ltd...

-

Page 31: Application Example

Please refer to the AQ-100 series manuals and the SAS booklet for more information regarding circuit breaker failure protection. **) AQ-1000, the secondary side incomer and the tie breaker are tripped when the circuit breaker failure protection is activated. Please refer to the AQ-100 series manuals and the SAS booklet for more information regarding circuit breaker failure protection. - Page 32 AQ-1000 Instruction manual Version: 1.04 Figure. 13. - 12. Connections of the example application. © Arcteq Relays Ltd...

-

Page 33: Technical Data

IF-D91B Fiber type: Arcteq AX-001 multicore glass ber 14.2. Device ratings Table. 14.2. - 3. Technical data for AQ-1000. Maximum busbar voltage 690 V AC 50/60 Hz (power frequency withstand voltage 1000 V AC) (line-to-line) (IEC rating): Maximum busbar voltage... -

Page 34: Auxiliary Voltage

15.0 kg (33 lbs) NOTE! The total system operation time is <4 ms (AQ-110P + AQ-1000). Power system studies which incorporate the Arcteq AQ-1000/AQ-110P system should use a clearing time of 5 ms for all assets protected by this system. -

Page 35: Environmental Ratings

14.6. Environmental ratings Table. 14.6. - 7. Environmental ratings. Environmental operating temperature (min…max): 5…70 °C (41…158 °F) Humidity (max): 95 % RH, no condensation allowed Storage temperature (min…max): –40… 85 °C (–40…185 °F) © Arcteq Relays Ltd... -

Page 36: Order Code

AQ-1000 Instruction manual Version: 1.04 15. Order code Figure. 15. - 13. Order code for AQ-1000. © Arcteq Relays Ltd... -

Page 37: Contact And Reference Information

Arcteq Relays Ltd. Visiting and postal address Wolf ntie 36 F 12 65200 Vaasa, Finland Contacts Phone: +358 10 3221 370 Fax: +358 10 3221 389 Website (general): www.arcteq. Website (technical support): support.arcteq. E-mail (sales): sales@arcteq. © Arcteq Relays Ltd...

Need help?

Do you have a question about the AQ-1000 and is the answer not in the manual?

Questions and answers