Subscribe to Our Youtube Channel

Summary of Contents for ELRO M300 Series

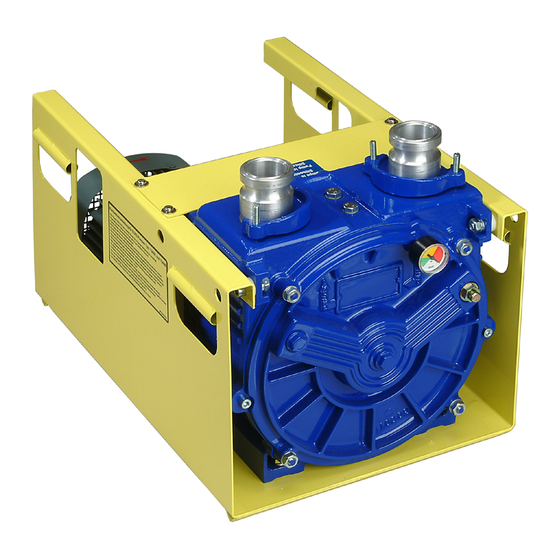

- Page 1 BA-M300-GB/10.19 Peristaltic Pumps Series M300 Series T300 Operating and Installation Instructions Installation, Operation and Maintenance www.cranechempharma.com...

- Page 2 ELRO Peristaltic Pumps Series M300 / T300 ® This is the translation of the original declaration of conformity for ELRO peristaltic pumps series M300 / T300. ®...

- Page 3 EC Declaration of Conformity in compliance with the Machinery Directive 2006/42/EC We hereby declare, that the pump units manufactured in series production Designation: ELRO Peristaltic Pump and ELRO peristaltic pump heads with/without mounting frame Series: M300, T300 Manufacturer: Crane Process Flow Technologies GmbH Heerdter Lohweg 63 - 71 40549 Düsseldorf...

- Page 4 The manufacturer Crane Process Flow Technologies GmbH, Heerdter Lohweg 63-71, 40549 Düsseldorf, declares that the pump units manufactured in series production Description: ELRO – Peristaltic Pump Series: M300 including drive and accessories Pump hose materials: NBR, CSM, NR all hoses are electrically conductive Connecting ports: Stainless steel, bronze;...

-

Page 5: Table Of Contents

ELRO Peristaltic Pumps Series M300 / T300 ® Table of contents Page Introduction ......................7 Warranty ........................7 Transport, storage ....................8 Principle of function ....................8 Safety ........................10 2.1. General information ....................10 Intended use ......................11 2.2.1 Unintended use Operation of pump .................... - Page 6 ELRO Peristaltic Pumps Series M300 / T300 ® Replacement of abutment ..................24 V-belt drive ......................25 5.5.1 Axial safety of the belt pulleys ................25 5.5.2 Checking the V-belt tension ................... 25 Lubricant change ....................25 5.6.1 Pump housing ......................25 5.6.2...

-

Page 7: Introduction

These instructions contain information for in- Warranty stallation, operation and maintenance of peri- The correct function of each ELRO peristaltic staltic pumps ELRO M300 and T300. pump is checked in the factory before ship- You should therefore thoroughly read these ment. -

Page 8: 1.2 Transport, Storage

ELRO Peristaltic Pumps Series M300 / T300 ® 1.2 Transport, storage In order to avoid any problems you should check the delivered goods against the delivery note for completeness and cor- rectness, make sure that for pumps with electric motor, combustion engine, water tur-... - Page 9 ELRO Peristaltic Pumps Series M300 / T300 ® The abutment 2 (Fig. 3) is an elastomer part and is installed in the pump section where the hose is squeezed to maximum extend. At the same time this abutment protects the pump housing against damage caused by solid particles in case of a hose breakage.

-

Page 10: Safety

ELRO Peristaltic Pumps Series M300 / T300 ® Safety General information Make sure that the pump is installed in com- pliance with all applicable national safety regulations. Always observe all applicable accident prevention instructions and implementing regulations. Transfer of media of Explosion... -

Page 11: Intended Use

ELRO Peristaltic Pumps Series M300 / T300 ® On pump systems with protective covering the product comes into contact and guards these must be properly assem- with the silicone or glycerine lubri- bled again before restarting. cant. When changing the delivery me-... -

Page 12: Conversions And Alterations To The Pump

ELRO Peristaltic Pumps Series M300 / T300 ® Strictly observe the operating instructions Operating safety of equipment for the drives in chapter “Appendix”. at risk. The non-observance of this note affects the operation- al reliability and can lead to Conversions and alterations to pump damage. -

Page 13: Health And Safety Information On Electric Equipment

ELRO Peristaltic Pumps Series M300 / T300 ® Always wear safety boots if there is a risk Pull out the mains plug. of heavy objects tipping over, slipping or The customer (or an ”authorized person” coming loose for any other reason, thereby appointed by him) is responsible for the causing danger for your feet. -

Page 14: Health And Safety Information On Lines Under Pressure

ELRO Peristaltic Pumps Series M300 / T300 ® 2.6.2 Health and safety information for cation instructions for these assemblies and work on lines under pressure components (see chapter “Appendix”). Always relieve the pressure before starting The complete system must generally be work on pressure lines. -

Page 15: Noise Emissions

ELRO Peristaltic Pumps Series M300 / T300 ® Noise emissions Use of pumps in potentially explosive environments In a room with several pumps you may experience an extreme development of When using pumps in explosive environ- noise. Depending on the sound pressure... -

Page 16: Notes On Installation And Use

For the installation of peristaltic pumps ELRO M300 without drive the following For the fill quantities, refer to Ch. 5.6) conditions must be met, so that the pump can be properly assembled together with... -

Page 17: Equipotential Bonding / Earthing

ELRO Peristaltic Pumps Series M300 / T300 ® of hoses. Camlock couplings DN 50 (female Vibration distance part) with 2” external thread should be used When installing and operating, a distance as matching parts. It is recommended to con- of a minimum of 10 cm between pump and tinue with a 2”... -

Page 18: Operating Instructions

ELRO Peristaltic Pumps Series M300 / T300 ® Operating instructions Check the lubrication of the drive unit. Make sure that all safety features are fas- Points to be observed before tened and fully functional. commissioning Camlock couplings must not be... -

Page 19: Maintenance

ELRO Peristaltic Pumps Series M300 / T300 ® Maintenance Fluids escaping under pressure can cause severe injury. Always observe the safety reg- Danger! Take care when loosening pres- Attention! ulations in chapter 2 when per- sure fittings, wear protective forming maintenance work! clothing. - Page 20 ELRO Peristaltic Pumps Series M300 / T300 ® can only be replaced by the manufactur- We recommend the operator of the peri- staltic pump to maintain an application and operation logbook, to provide evidence of n Loose connections and damaged parts...

-

Page 21: Cleaning

ELRO Peristaltic Pumps Series M300 / T300 ® Pumps with electric drive must Always wear protective clothing generally be switched off and when working with solvents or disconnected from the electric cleansing agents. Caution! power supply before starting Housing, cooling fins, openings and covers... - Page 22 ELRO Peristaltic Pumps Series M300 / T300 ® The following materials are available: fastening screw into the forcing bore M 10 (Fig. 10). Colour code Loosen and remove both holding clamps Natural rubber (NR) yellow and pumping hose (Fig. 11).

- Page 23 ELRO Peristaltic Pumps Series M300 / T300 ® Fig. 10 Disassembly of rotor Fig. 12 Disassembly of pumping hose Fig. 11 Disassembly of holding claws Fig. 13 Disassembly of pumping hose The O-rings at the hose ends 10. Slide the O-rings over both must be properly in their connecting sockets.

-

Page 24: Replacement Of Separating Part

ELRO Peristaltic Pumps Series M300 / T300 ® Fig. 14 Fig. 15 Abutment Separating part Abutment fastening screws Holder for separating part Tighten by hand to allow the separating Replacement of separating part part to align itself. The installed separating part has the... -

Page 25: V-Belt Drive

ELRO Peristaltic Pumps Series M300 / T300 ® screws (part-no.1020, Fig. 8) and lift the Reassemble the side plates. abutment out of the housing (Fig. 15). Lubricant change, lubricant Clean the housing thorough- qualities ly before assembling the new abutment. -

Page 26: 6.0 Spare Parts

ELRO Peristaltic Pumps Series M300 / T300 ® 6.0 Spare parts Spare parts storage Since the extent of the recommended spare parts storage depends on the period of use and the different operating conditions for the pumps, you should consult the manufactur- er or an authorized dealer. -

Page 27: Troubleshooting

ELRO Peristaltic Pumps Series M300 / T300 ® Troubleshooting Fault Possible cause Remedy No pump flow Pressure and suction valves Open valves closed Wrong direction of rotation Reverse direction of rotation, Check supply line (phase) Suction line blocked Remove blockage... - Page 28 ELRO Peristaltic Pumps Series M300 / T300 ® Fault Possible cause Remedy Pump looses suction abilities Leaks in suction line Find and seal leaks Suction head too high or air Increase suction pressure, degas or gas in fluid fluid Pump worn...

- Page 29 ELRO Peristaltic Pumps Series M300 / T300 ® Fault Possible cause Remedy Pumping hose service life Chemical attack. Hose swollen Check chemical compatibility of insufficient or peeling hose material on the basis of the resistance list, if necessary contact the authorized dealer or manu- facturer.

-

Page 30: Noise Emissions

ELRO Peristaltic Pumps Series M300 / T300 ® Appendix I Type Noise emission [dB] 7,5 E 10 E 10 Ex 10 EW 15 E 15 EX 15 R 20 E T300 E 21 E 21 EX 15 D 20DF 20 D... - Page 31 ELRO Peristaltic Pumps Series M300 / T300 ® Appendix II Please observe also the operating instructions for the respective drive unit. M300 pump series: Electric motor Electric motor explosion protected Gasoline engine Diesel engine Water turbine Hydraulic motor Pneumatic motor...

-

Page 32: Recommendations For Use

ELRO Peristaltic Pumps Series M300 / T300 ® Recommendations for use Rubber materials for pumping hoses Designation Properties chemically dependent thermally Recommendation resistant1 resistant2 resistant usable Natural rubber Natural material diluted acids and concentrated - 20 to + 80°C Sewage plants,... - Page 33 ELRO Peristaltic Pumps Series M300 / T300 ® Note on Declaration of no Objection We want to protect our employees against dangers through contaminated devices and allow the timely handling of your return. Please understand for this reason that we can only accept your shipment upon submission of our declaration of no objection including return number.

- Page 34 ELRO Peristaltic Pumps Series M300 / T300 ®...

- Page 35 ELRO Peristaltic Pumps Series M300 / T300 ® This is the translation of the original operating and installation instructions for ELRO peristaltic pumps series M300 / T300. ® For the original version in German, please refer to www.cranechempharma.com...

- Page 36 ELRO Peristaltic Pumps Series M300 / T300 ® Crane Process Flow Technologies GmbH P.O.Box 11 12 40, D-40512 Düsseldorf Heerdter Lohweg 63-71, D-40549 Düsseldorf Phone +49 211 5956-0 +49 211 5956-111 infoDus@cranecpe.com www.elropumps.com www.cranecpe.com We reserve the right to change all technical information.

Need help?

Do you have a question about the M300 Series and is the answer not in the manual?

Questions and answers