Table of Contents

Advertisement

Quick Links

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety information.

Failure to comply with these instructions will result in voiding of the product warranty and may result in personal

injury and/or property damage.

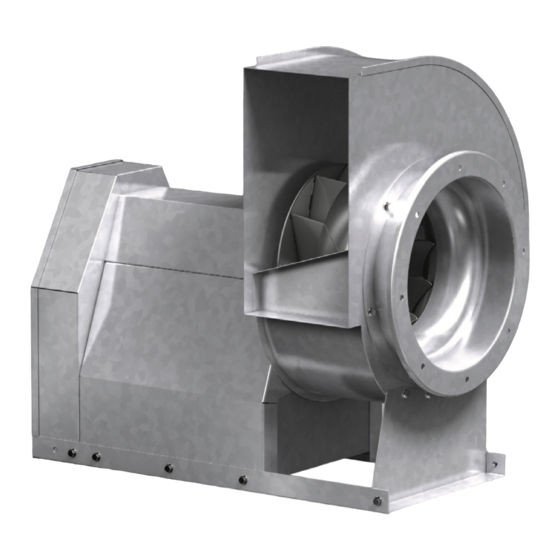

Model CSB Centrifugal Single Width Blower

The single-width centrifugal blower is designed for supply,

exhaust or return air installations. Performance capabilities range

up to 17,000 cmh and up to 5.8 in. wg. of static pressure.

CSB fans are available in 8 sizes with wheel diameters ranging

from 315 - 710 mm. Each fan shall bear a permanently affixed

manufacturer's engraved metal nameplate containing the model

number and individual serial number.

General Safety Information

Only qualified personnel should install this unit.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before

moving forward.

1. Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), the National

Fire Protection Agency (NFPA), where applicable.

2. The rotation of the wheel is critical. It must be

free to rotate without striking or rubbing any

stationary objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan wheel faster than the maximum

cataloged fan RPM. Adjustments to fan speed with

Variable Frequency Drives (VFD) may affect motor

load. If the fan RPM is changed, the motor current

should be checked to make sure it is not exceeding

the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with

the equipment.

7. Never open access doors to a duct while the fan

is running.

®

DANGER

Always disconnect power before working on or near

a unit. Lock and tag the disconnect switch or breaker

to prevent accidental power up.

CAUTION

When servicing the unit, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

Centrifugal Single-Width Blower

Document 484640

Model CSB

1

Advertisement

Table of Contents

Summary of Contents for Greenheck CSB

- Page 1 Performance capabilities range up to 17,000 cmh and up to 5.8 in. wg. of static pressure. CSB fans are available in 8 sizes with wheel diameters ranging from 315 - 710 mm. Each fan shall bear a permanently affixed manufacturer’s engraved metal nameplate containing the model...

- Page 2 Receiving should be evenly maintained between 30° to 110°F (-1° to 43°C), wide temperature swings may cause Upon receiving the product, check to ensure all items condensation and “sweating” of metal parts. All are accounted for by referencing the delivery receipt or accessories must be stored indoors in a clean, dry packing list.

-

Page 3: Table Of Contents

Table of Contents Removing from Storage As fans are removed from storage to be installed in System Set-Up ......4 their final location, they should be protected and Installation maintained in a similar fashion until the fan equipment... -

Page 4: System Set-Up

POOR GOOD 3/4 to 3/4 to One fan one fan One fan one fan wheel wheel diameter wheel diameter GOOD diameter diameter System Set-Up Ducted Outlet Installations Discharge Duct Turns - Duct turns located near the Installations with inlet or discharge configurations that fan discharge should always be in the direction of the deviate from this manual may result in reduced fan fan rotation. -

Page 5: Installation

Installation V-Belt Drive Installation 1. Remove the protective coating from the end of the Move the fan to the desired location. Check and fan shaft using mineral spirits or another similar tighten fasteners throughout the unit and then fasten solvent. Check to ensure that the shaft is free of securely through mounting holes provided in the base MOTOR MOTOR... -

Page 6: Unit Start-Up

Unit Start-Up Additional Steps for Initial Start-Up 1. Check for proper wheel rotation by momentarily WARNING energizing the fan. Access to view the wheel can be gained through the blower housing access panel. Disconnect and secure to the OFF position all electrical power to the fan prior to inspection Airflow One of the most frequently encountered problems... -

Page 7: Routine Maintenance And Operation

Belt Span inch of belt span. For more information about measuring belt tension, refer to Greenheck’s Product Application Guide, FA/127-11, Measuring Belt Tension, found online at www.greenheck.com in the library section. Check belt tension two times during the first 24 hours of operation and periodically... -

Page 8: Bearing Lubrication Schedule

Bearing Lubrication Schedule Wheel and Fastener Maintenance Shaft bearings are the most critical moving part of a Wheels require very little attention when exhausting fan. Therefore, special attention should be given to clean air, however, air heavily laden with grease or keeping the bearings clean and well lubricated. -

Page 9: Bearing Replacement

Consult fan manufacturer for instructions on the removal of replacement motors. It is recommended to select VFD compatible motors for CSB fans and connect the motors through a VFD controller to avoid sudden torque on the impeller, and the belts ensuring soft start and safe operation. -

Page 10: Troubleshooting

Troubleshooting WARNING Before taking any corrective action, make certain unit is not capable of operation during repairs. Problem Cause Corrective Action Adjust wheel and/or inlet cone. Wheel Rubbing Inlet Tighten wheel hub or bearing collars on shaft. Tighten sheaves on motor/fan shaft. Adjust belt tension. V-Belt Drive Align sheaves properly (see procedure). -

Page 11: Maintenance Log

Maintenance Log Date _______________ Time _______________ AM/PM Date _______________ Time _______________ AM/PM Notes: __________________________________________ Notes: __________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ Date _______________ Time _______________ AM/PM Date _______________ Time _______________ AM/PM Notes: __________________________________________ Notes: __________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________... -

Page 12: Our Commitment

Our Commitment As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without notice. Specific Greenheck product warranty is found in the Model Specification located on greenheck.com.in within the product area tab and in the Technical Data Library.

Need help?

Do you have a question about the CSB and is the answer not in the manual?

Questions and answers