Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for CLN Fusion

- Page 1 CLN Fusion Manual...

- Page 2 CLN Fusion Manual Safety Machine Overview Maintenance Operation Software Overview 2336 Cypress Lane, Belle Glade, FL 33430 Toll- Free: (877) 256- 1043 Fax: (561) 996-5050 www.clnofsfl.com...

- Page 3 Important Make sure you read and fully understand this manual before operating your automated machine. Failure to do so will put yourself and others in harm and will void the warranty of this equipment. CLN Fusion Manual Ver. 1...

-

Page 4: Intended Use Of Machine

• Aluminum Coiled Stock Material in Depths of (but not limited to): • 1.5” • 2.0” • 3.0” • 5.3” • Machines are not intended for: • Bending, Notching, Flanging, or Shearing steel or similar materials. CLN Fusion Manual Ver. 1... - Page 5 Introduction Disclaimer Everyone at CLN of South Florida, Inc. would like to thank you for purchasing the CLN Brand Bending Machine. We understand that you had a choice and CLN of South Florida, Inc. makes every effort to provide you picked ours. Before you get started, there are a their valued customers with current and accurate few things that we need to go over.

- Page 6 Table of Contents Safety Machine Overview Maintenance Machine Operation Software Overview CLN Fusion Manual Ver. 1...

- Page 7 Safety Your Responsibilities: • As an operator of the CLN machine, you are responsible to follow all safety procedures. Any person who operates or does any maintenance on this machine must be aware of all safety procedures. Safety Precautions: •...

- Page 8 • Your machine should be located in a clean environment. • Keep your machine and work area free of dirt and debris. • Lighting • Your machine should be operated in a well lighted area. CLN Fusion Manual Ver. 1...

-

Page 9: Caution Labels

The machines computer and monitor are the only two components that will remain on with the emergency stop pressed. CLN Fusion Manual Ver. 1... -

Page 10: Machine Overview

Machine Overview Components Overview Install Layout Footprint Assembly Electricity Compressed Internet Installation CLN Fusion Manual Ver. 1... -

Page 11: Components Overview

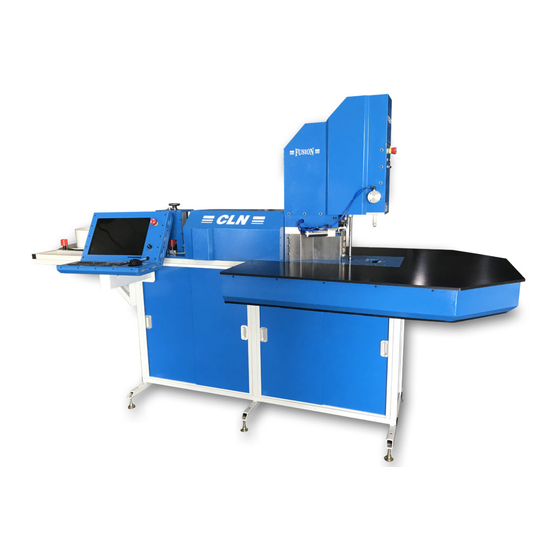

Components Overview: *Machine displayed with the covers removed. CLN Fusion Manual Ver. 1... - Page 12 • The Decoiler aids in feeding the material through the machine. It is very important that the Decoiler is at the same height as the CLN Fusion so that the material enters the machine at the same height that it leaves the decoiler.

- Page 13 If there is a discrepancy the encoder tells the motor to make a correction. The encoder is located just after the rollers and before the homing cell. CLN Fusion Manual Ver. 1...

- Page 14 Degree notcher and the second is a 100 degree notcher. The 30 degree notcher is used for negative bends and radius bends, as well as a 6 inch repeating relief notch for the flanger. The 100 degree notch is used for positive brake bends. CLN Fusion Manual Ver. 1...

- Page 15 • The Bending Tool Assembly has clamping brake bend dies which allow for a sharper brake bend. When making a radius bend these dies will rotate out of the way allowing the machine to roll form smooth radiuses. CLN Fusion Manual Ver. 1...

-

Page 16: Installation Layout

Make sure you have at least 48” of clear work space around the perimeter of Installation Layout: the entire machine to ensure a safe working area for the machine operator. CLN Fusion Manual Ver. 1... -

Page 17: Machine Footprint

Machine Footprint: CLN Fusion Manual Ver. 1... - Page 18 Remove the top of the crate. • Remove either one of the long side walls of the crate. • Unbolt the Fusion Machine from the base of the crate. • The Angle Brackets located in the front of the Fusion Machine are positioned to accept the Catch Table Frame, DO NOT unbolt or move these brackets.

- Page 19 Machine Set Up: • Remove the Side Doors of the Fusion Machine. • Install the computer on the shelf. • Install the monitor on the monitor and keyboard support bracket. CLN Fusion Manual Ver. 1...

- Page 20 • Slide the monitor and keyboard support bracket into the t-slot of the machine frame. • Drop the wires for the keyboard and mouse into the frame and plug them into the computer. CLN Fusion Manual Ver. 1...

- Page 21 • Slide in the black plastic catch table into the catch table support frame and fasten it to the frame using the 5/16 – 18 Flat Head Cap screws and T-Slot nuts provided in a small plastic bag. CLN Fusion Manual Ver. 1...

- Page 22 • The Chip Collection Bucket clips in to the rear of the machine. • Install the Straightener to the rear of the machine. CLN Fusion Manual Ver. 1...

- Page 23 • A 6ft cord is supplied with the machine. • Plug the female end of cord into the outlet on the rear of the machine. • Plug the male end of the cord into the 20 amp outlet installed by your electrician. CLN Fusion Manual Ver. 1...

-

Page 24: Compressed Air Supply

• An air compressor with a minimum capacity of 5 CFM at 80 PSI is required for the machine to function. • When the air line is connected to the machine, the gauge on the air regulator should read 80 psi. CLN Fusion Manual Ver. 1... - Page 25 • Our customer support team can log onto your machine through a software call Team Viewer if you need assistance. For this software to work properly you must be connected to the internet. CLN Fusion Manual Ver. 1...

-

Page 26: Machine Maintenance

• Apply a light weight lubricant such as WD-40 to Notcher Dies and Shear Blades daily. • Empty the Notch Chip Collection Bin daily or as needed. • Check the Air Filter Regulator for moisture every four hours and drain by pressing up on the bottom fitting as needed. CLN Fusion Manual Ver. 1... -

Page 27: Grease Locations

Grease Locations: Apply all purpose grease to these locations weekly or as needed. CLN Fusion Manual Ver. 1... -

Page 28: Machine Operation

Machine Operation Turning the Machine on Compressed Loading Material Mechanical Adjustments CLN Fusion Manual Ver. 1... - Page 29 You will have to open one of the door closest to the operator in order to gain access to the power switch. • Wait for the computer to completely boot up. CLN Fusion Manual Ver. 1...

- Page 30 The gauge on the machine should read 80 psi. • In order for the machine to function properly your air compressor should have a minimum capacity of 5 cfm at 80 psi. CLN Fusion Manual Ver. 1...

- Page 31 Feed the material in until it has moved passed the second roller. • Make sure the material is seated firmly in both of the bottom V Groove Rollers. • Now lower the top V Groove Rollers and tighten. CLN Fusion Manual Ver. 1...

- Page 32 0.25” flange, and the highest slot will produce a flangeless letter. *Note, if you are running with the V Groove Rollers in the flangeless slot you will want to turn the Notcher/ Flanger Off. (See Tool Settings) CLN Fusion Manual Ver. 1...

- Page 33 Loosen the four bolts on the rear of the Notcher Base that you wish to adjust. • Adjust the jack bolt to raise or lower the notch depth. • Once your depth is adjusted tighten the four bolts on the rear of the Notcher Base. CLN Fusion Manual Ver. 1...

- Page 34 Loosen the ½-20 bolt that is threaded into the Bending Ram Plate to lower the Bending Ram. This will cause the machine to bend a greater angle. (*It may be helpful to tap the Bending Ram with a soft hammer while making adjustments.) CLN Fusion Manual Ver. 1...

- Page 35 There are two Shear Shims, one on the Fixed Die and one on the Moving Die Side. • Now make an adjustment as needed and retighten the bolts. • Release the Emergency Stop and Restart the software. CLN Fusion Manual Ver. 1...

-

Page 36: Software Overview

• Software The purpose of the CLN software is to give the operator a way to view the artwork that was sent via a DXF and convert it so that the machine can process the information correctly. From the CLN Software you can only alter the start point and split the letter into two parts, but that’s it. It has nothing to do with artwork generation or modification. - Page 37 This routine calculates what the router bit can’t cut and compensates for it by subtracting out the difference from the two lines that create a negative angle. The setting is called Router Bit Size and is in Options > Software Settings. Curfing Loss Original Artwork Actual letter back after being cut on the CNC Router CLN Fusion Manual Ver. 1...

- Page 38 • To open the operating software on the machine simply double click on the desktop icon “CLN Fusion”. • A message will display asking you if it is safe to home the bend head. (Please see Homing the Bend Head) CLN Fusion Manual Ver. 1...

- Page 39 Bend Head. Therefore if you click “Run Tool” the message will display again asking you if it is safe to home the Bend Head. CLN Fusion Manual Ver. 1...

- Page 40 • The Artwork will be displayed on the screen and is for viewing purposes only. • You can only alter your start point via the CLN Software, any other Artwork Manipulation should be done in your artwork set up procedure. CLN Fusion Manual Ver. 1...

- Page 41 Run Tool. • To select the letter you can either click on the letter or click on Next and the software will cycle through the letters and highlight the one you have selected in blue. CLN Fusion Manual Ver. 1...

- Page 42 Once you click Ok the machine will move the material. Homing Material • To Home the material, click Home. The machine will bring the material all the way back to the starting position. CLN Fusion Manual Ver. 1...

- Page 43 • Now the Shearing cycle is complete and the Shear will automatically retract without the need for the operator to hold the button. Back to Shear Adjustment CLN Fusion Manual Ver. 1...

- Page 44 Head if you find you are not making break bends at the correct angle. • If you find that your machine is not making bends at the correct angle you can make adjustments to the Bend Offsets in “Material Settings” CLN Fusion Manual Ver. 1...

- Page 45 • These are settings based on the thickness of material that you are running. • The Fusion is capable of handling a multiple sizes of materials from 0.032” to 0.063”. • When bending metal material there is a certain degree...

- Page 46 • Bump Feed Distance: This is the length of material to be fed through the machine during a bump bending routine. *These are settings are being used as an example. Actually Material Settings will CLN Fusion Manual Ver. 1 vary.*...

- Page 47 *These are settings are being used as an Note: Typically happens on the inside of an upper case “H” The outside example. Actually Material Settings will of the “H” is controlled by the outline from the cad program. CLN Fusion Manual Ver. 1 vary.*...

- Page 48 • Registration Code: Depending on your payment plan your machine has a code that will make the machine unusable after a certain period of time. Once your machine has been completely paid for you will receive a payoff code. CLN Fusion Manual Ver. 1...

- Page 49 Actually Tool Settings will vary.* not perform functions as it should. • Motor Settings: This settings are in counts and are used to calibrate the machines feed and bending motors. CLN Fusion Manual Ver. 1...

Need help?

Do you have a question about the Fusion and is the answer not in the manual?

Questions and answers