Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Vivid Matrix Omni-Flow

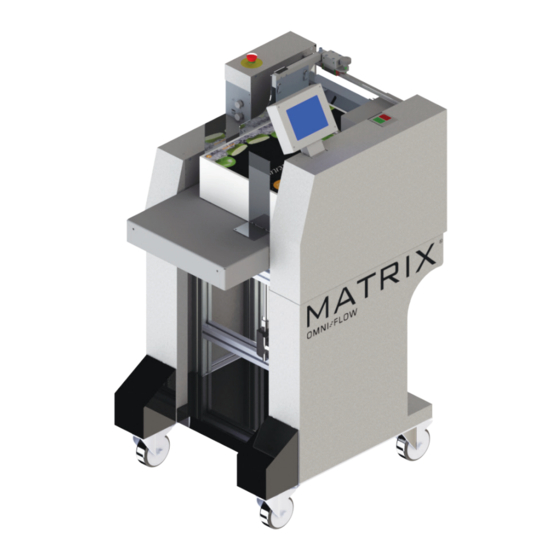

- Page 1 Product Instruction Manual Omni-Flow Feeder The Matrix has been designed to be user friendly, however we strongly recommend you take a few minutes to read through this manual to ensure correct operation. Keep this manual safe for future reference.

-

Page 2: Table Of Contents

Operating manual Omni-Flow Chapter Page List of contents Short description of the feeder ............. 4 About this instruction manual .............. 4 Safety ...................... 5 Technical Data..................7 Component locator ................8 Installation .................... 11 Operation....................12 Operation and functions of the display ..........16 Accessories.................. - Page 3 Operating manual Omni-Flow List of contents Short description of the feeder ............. 4 About this instruction manual............... 4 Scope........................4 Limitations......................4 Organisation ......................4 Safety ...................... 5 Safety instructions ....................5 Safety equipment ....................6 Technical Data..................7 Machine dimensions ....................7 Component locator ................8 Overview........................8 Front view ......................9 Operating panel ....................10...

- Page 4 Operating manual Omni-Flow Starting the display ......................17 Start screen ........................17 Main menu ........................18 0-8-0 Menu Speed ......................18 1-0-0 Menu Counter .......................19 1-2-0 Menu Modifying batch size ..................19 1-3-0 Menu Modifying batch number ................20 1-4-0 Menu Modifying batch interval ................20 1-5-0 Menu Modifying sheet counter ................20 2-0-0 Menu Sheet size ....................21 2-1-0 Menu Paper size basic ..................21 2-1-2 Menu Modifying sheet length and width ..............21...

-

Page 5: Short Description Of The Feeder

Operating manual Omni-Flow 1 Short description of the feeder The feeder is a universal paper feeding system that can be used online in production lines together with Vivid machines as well as machines from other manufacturers. The feeder picks sheets from a pile and feeds them precisely into Matrix. -

Page 6: Safety

The device should not be disassembled, modified or repaired. The device contains parts that are under high voltage. Always contact Vivid service dept and local dealer if the device needs repair. Sprays or solvents should not be used in the vicinity of the device. For information on machine maintenance, please refer to chapter 6.1.3. -

Page 7: Safety Equipment

Operating manual Omni-Flow Safety equipment The feeder is a safe machine as long as it is properly operated. However, it does feature some safety equip- ment in order to prevent injury or material damages. Emergency STOP In any case, the Emergency STOP button will be pressed, the feeder stops immediately. As long as the button is locked, the machine cannot be started. -

Page 8: Technical Data

Operating manual Omni-Flow 4 Technical Data Feeder system suction feeder Control panel touchscreen Feeder capacity 180 mm Double sheet detection ultrasonic Minimum size 105 x 148 mm Weight Minimum 2,5 m/min, 375 x 660 mm Maximum size Speed Maximum 45 m/min 375 x 1050 mm* (Optional 60 m/min) Paper stocks... -

Page 9: Component Locator

Operating manual Omni-Flow 5 Component locator Overview Double sheet detector Guide angle short Infeed conveyor Stacking table Stacking table height setting Operating panel Touchscreen display = non-operating side = operating side Edition 1.0. 09/2017 8 / 32... -

Page 10: Front View

Operating manual Omni-Flow Front view Operating Manual Omni-Flow Vivid machine plate Blow air channels Adjusting knob for paper gap Paper lock Adjusting knob for air blowers Conveyor belts Side guide Edition 1.0. 09/2017 9 / 32... -

Page 11: Operating Panel

Operating manual Omni-Flow Operating panel Operating panel : Operating panel and emergency STOP LED green "ON" STOP button - Flashing: Machine is ready. Stops the machine. - Lit: Processing active. UP button ... - Page 12 Operating manual Omni-Flow Operating panel Operating panel : Operating panel and emergency STOP LED green "ON" STOP button - Flashing: Machine is ready. Stops the machine. - Lit: Processing active. UP button ...

-

Page 13: Installation

Operating manual Omni-Flow 6 Installation Installation instructions During the whole installation process (chapter 6), the machine or any of its parts must not be connected to power. 6.1.1 Installation location The unit must be installed on a flat surface. If necessary it can be adjusted horizontally with the height ad- justable feet. -

Page 14: Operation

Operating manual Omni-Flow 7 Operation Lower the stacking table Slide the side guide to the side Loosen the adjusting screw and slide the side Use the button on the operation panel to guide to the OP side. ... -

Page 15: Setting The Blow Air Channels

Operating manual Omni-Flow Setting the blow air channels Set the air blow air channel using the adjustment wheel for the blow air channel Using the adjustment wheel for the sheet separator the space between the sheet separator and the ... -

Page 16: Stacking Table Height And Setting

Operating manual Omni-Flow Stacking table height and setting Anticlockwise rotation will increase the distance of the conveyor belts relative to the paper. Fanned out paper is made more compact. Clockwise rotation will decrease the distance of the conveyor belts relative to the paper. -

Page 17: Test Sheet

Operating manual Omni-Flow Test sheet 1. In order to activate the test sheet, Matrix Laminating System is switched on, the paper is aligned (chapter 7), the channels are set (chapter 7.1) and the job details are entered. For more detailed information on entering a job see from chapter 8. -

Page 18: Operation And Functions Of The Display

Operating manual Omni-Flow 8 Operation and functions of the display Numeric keypad The numeric keypad is used for entering parameter values. Depending on the parameter type the buttons are empty or additional buttons are displayed. Button: Description: 1..9, 0 When the first character is entered, the current value is automatically cleared. -

Page 19: Display Busy

Operating manual Omni-Flow Display busy! The busy symbol is displayed for functions for which a certain state or position must be waited for. During this display (hourglass in the middle of the screen) the display keypad is locked. Starting the display During booting, version number and date of creation are displayed. -

Page 20: Main Menu

Menu Sheet size Batch number for 5 seconds. Menu Speed Menu Fans Menu Job VIVID Menu Customer ser- vice / Info / Service Standardized format sheet length Paper thickness Unmodified jobs are displayed in a black font. -

Page 21: Menu Modifying Batch Size

Operating manual Omni-Flow 1-0-0 Menu Counter In this menu the coun- Set counters Total ters are set or reset. sheet, Batch size and Batch number to zero. This function cannot be undone using the Undo button. Menu Batch size Discard modifications and display the main Menu Batch number menu. -

Page 22: Menu Modifying Batch Number

Operating manual Omni-Flow 1-3-0 Menu Modifying batch number The batch number de- termines the number of stacks to be created. Discard modifications and display the menu Counters. Provisionally apply modifications and display the menu Counters. 1-4-0 Menu Modifying batch interval The batch interval de- termines the distance between stacks. -

Page 23: Menu Sheet Size

Operating manual Omni-Flow 2-0-0 Menu Sheet size Menu Sheet size for standard paper sizes Active paper stocks (highlighted green) Discard modifications display the main menu Modifications take over. If the paper size changed the menu en- try sequence is started otherwise, the main menu appears. -

Page 24: Menu Job

Operating manual Omni-Flow 5-0-0 Menu Job Menu Loading job VIVID Menu Saving job Menu Deleting job Display main menu Displayed fields with job details: Line 1: Can be used for order number. This field may be left blank (16 characters max.). -

Page 25: Menu Deleting Job, Selection Via Cursor Buttons

Operating manual Omni-Flow 5-1-0 Menu Loading job, selection via filter Display the menu with VIVID selection via cursor Deletes the last char- Switch between search acter in the search field line 1 or 2 (deletes field Button to delete the... -

Page 26: Menu Deleting Job, Selection Via Filter

Operating manual Omni-Flow 5-3-0 Menu Deleting job, selection via filter Functions and display Display the menu with are the same as in Load- VIVID selection via cursor ing job. Switch between search field line 1 or 2 (deletes the current search field). -

Page 27: Menu Fans

Operating manual Omni-Flow 9-0-0 Menu Fans Showing / hiding the Single sheet setting buttons for suc- tion feeder. Switches the function of the button with a dual Showing / hiding the function. setting buttons for blower feeder. Discard modifications and display the main menu. -

Page 28: Menu Information

Operating manual Omni-Flow 10-2-0 Menu Information Omni-Flow Menu Software infor- Machine type: mation Folding and creasing section IP address if connect- ed with active DHCP. Total counter not resettable NetBios name for ac- Display menu Custom- cess via Explorer er service / Info / Ser- vice. -

Page 29: Menu Modifying Vacuum Length

Operating manual Omni-Flow 10-4-2 Menu Modifying vacuum length The absolute vacuum distance is calculated from the vacuum length and the offset value. Discard modifications and display the menu Spacing. Apply modifications and display the menu Spacing. 10-4-3 Menu Modifying sheet distance Discard modifications and display the menu Spacing. -

Page 30: Menu Sheet Running Control (Optional)

Operating manual Omni-Flow 10-11-0 Menu Sheet running control (optional) When the Photo mode is Single sheet configured, an additional button is displayed Photo mode for insert Discard modification (marked in red = off) and display Customer service - Information service menu. Adopt modification and display Customer service - Information... -

Page 31: Menu Warnings

Operating manual Omni-Flow 10-5-0 Menu Warnings Error or malfunction in active or inactive state. Changes back to the menu Information. Warning symbols Active Inactive Description One or more motor temperatures are too high. 8-0-0 Menu Error display Error or malfunction in active or inactive state. - Page 32 Operating manual Omni-Flow The error must be manually acknowledged, in the state active - inactive: Paper jam Emergency stop active External emergency active Motor error Double sheet detected Feeder paper stack Setup data error Errors that are acknowledged automatically when the condition is inactive: Hood Error fan...

- Page 34 Operating manual Omni-Flow Notes Edition 1.0. 09/2017 32 / 32...

- Page 35 Your Matrix Laminator rollers are covered against manufacturing defects, the warranty does not cover against any damages caused by operator misuse. Your warranty will be void if the System has been modified by a third party not approved by the manufacturer (Vivid Laminating Technologies) to carry out such alterations.

Need help?

Do you have a question about the Matrix Omni-Flow and is the answer not in the manual?

Questions and answers