Table of Contents

Advertisement

Quick Links

INSTRUCTION MANUAL

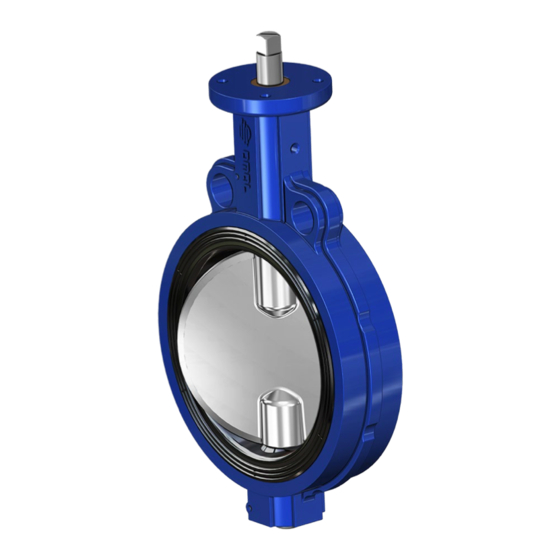

BUTTERFLY VALVES

ITEM 375 - 376 -377 , 385 - 386 - 387

OMAL S.p.A.

Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy •

Production Site:

Via Brognolo, 12 - 25050 Passirano (BS) Italy

Ph.

+39 030 8900145 •

Fax

+39 030 8900423 • info@omal.it •

www.omal.it

1

EN -

Rif. UMA0082W - 10/19

Advertisement

Table of Contents

Summary of Contents for omal automation 375

- Page 1 INSTRUCTION MANUAL BUTTERFLY VALVES ITEM 375 - 376 -377 , 385 - 386 - 387 OMAL S.p.A. Headquarters: Via Ponte Nuovo, 11 - 25050 Rodengo Saiano (BS) Italy • Production Site: Via Brognolo, 12 - 25050 Passirano (BS) Italy +39 030 8900145 •...

- Page 2 INSTRUCTION MANUAL BUTTERFLY VALVES ITEM 375 - 376 -377 , 385 - 386 - 387 INDEX: Pag. GENERAL FEATURES WORKING CONDISTIONS OPERATING INFORMATION SAFETY INFORMATION INSTALLATION INSTRUCTION MATERIALIAL AND THEIR DURABILITY MAINTENANCE VERSIONI SPECIALI STORAGE TROUBLE SHOOTING DISPOSAL OF PRODUCTS AT THE END OF LIFE...

-

Page 3: General Features

2.3 Working temperature The butterfly valves type 375 - 376 - 377 - 385 - 386 - 387 series (A 536 spheroidal cast iron body) are designed and tested for a continuous use keeping the PN value unchanged throughout the whole range of temperatures. Below the maximum and minimum working temperatures for seal material: NBR: - 23°C + 82°C... -

Page 4: Operating Information

INSTRUCTION MANUAL BUTTERFLY VALVES ITEM 375 - 376 -377 , 385 - 386 - 387 • Address of the manufacturer • Model / Product Code • Min./max. Temperature • Production date • Materials (body, disc and seal) • CE marking according to Directive 2014/68/EU 3. -

Page 5: Safety Information

INSTRUCTION MANUAL BUTTERFLY VALVES ITEM 375 - 376 -377 , 385 - 386 - 387 A) DIRECT MOUNTING Valve actuator direct mounting is the best solution to avoid plays between valve stem and actuator drive shaft. For a direct mounting you should have the same standard flange connection on valve and actuator as well as the valve stem dimensions that fit perfectly with the actuator drive. -

Page 6: Installation

INSTRUCTION MANUAL BUTTERFLY VALVES ITEM 375 - 376 -377 , 385 - 386 - 387 • A valve is a safe product provided that it is properly installed between flanges on a plant. If you want to test a valve at the bench, especially a pneumatically operated one, make sure there are protections enough to prevent objects and parts of your body to get caught between the butterfly and the valve body. -

Page 7: Maintenance

INSTRUCTION MANUAL BUTTERFLY VALVES ITEM 375 - 376 -377 , 385 - 386 - 387 6. MATERIALS AND THEIR DURABILITY To ensure the full reliability of the valve, it is recommended to carry out at least once a year, a check of the efficiency level of the plant, changing all the worn-out parts promptly where leakage or straining occur, both inside the pipeline and towards the outside of the valve. - Page 8 INSTRUCTION MANUAL BUTTERFLY VALVES ITEM 375 - 376 -377 , 385 - 386 - 387 Body Disc Liner Upper shaft Lower shaft Lower O-ring LUG BODY Upper bush Shaft bush Elastic pin 10* Shaft O-ring * Spare parts kit (KGF) DN 350 ÷...

-

Page 9: Special Version

INSTRUCTION MANUAL BUTTERFLY VALVES ITEM 375 - 376 -377 , 385 - 386 - 387 WARNING To make sure there is no pressure in the pipeline, before servicing a valve. If a dangerous or aggressive fluid flows through the pipe- line, always wash the pipeline as suggested by the manufacturer. -

Page 10: Troubleshooting

INSTRUCTION MANUAL BUTTERFLY VALVES ITEM 375 - 376 -377 , 385 - 386 - 387 10. TROUBLE SHOOTING POTENTIAL EFFECTS OF FAILURE POTENTIAL FAILURE MODE SOLUTIONS Check the maneuvering system Incomplete closing of the disc / Contact OMAL Replace worn parts as per instruction... -

Page 11: Declaration Conformity

INSTRUCTION MANUAL BUTTERFLY VALVES ITEM 375 - 376 -377 , 385 - 386 - 387 11. DISPOSAL OF PRODUCTS AT THE END OF LIFE The OMAL butterfly valves are designed so that when they are at the end of their life cycle they can be completely disassembled, separating the different materials for the proper disposal and/or recovery.

Need help?

Do you have a question about the 375 and is the answer not in the manual?

Questions and answers