Table of Contents

Advertisement

Quick Links

EFFECTIVE: September 23, 2019

HPC500

Series

Top Running

and

Underhung

End Trucks

½ Ton, 1 Ton, and 2 Ton Capacity

Code and Serial No.

This equipment should not be installed, operated or

maintained by any person who has not read and understood

all the contents of this manual. Failure to read and comply

with the contents of this manual can result in serious bodily

injury or death, and/or property damage.

Advertisement

Table of Contents

Summary of Contents for KITO HARRINGTON HPC500 Series

- Page 1 EFFECTIVE: September 23, 2019 HPC500 Series Top Running Underhung End Trucks ½ Ton, 1 Ton, and 2 Ton Capacity Code and Serial No. This equipment should not be installed, operated or maintained by any person who has not read and understood all the contents of this manual.

-

Page 2: Table Of Contents

Table of Contents Section Page Number 1.0 Important Information and Warnings………………………………………………….………………….4 Terms and Summary Warning Tags and Labels 2.0 Technical Information………………………………………………………………………..…..…….…..7 Specifications Part Names 3.0 Pre-operational Procedure…………………………………………………..…….........11 Runway Bridge Beam End Trucks Pre-operational Checks and Trial Operation 4.0 Operation………………………………………………………………………………………………….19 Introduction Important Information about Operation 5.0 Inspection………………………………………………………………………………………….……...20 General... - Page 3 6.0 Lubrication……………………………………………………………………….……..…..…...……25 HPC500 End Trucks Other Equipment Maintenance & Handling……………………………………………………………………………26 General Storage Outdoor Installations Troubleshooting ……………………………………………………………………..…….….…….27 Warranty………………………………………………………………………………...……...……28 10.0 Parts List……………………………………………………………………………...……….……..29...

-

Page 4: Important Information And Warnings

1.0 Important Information and Warnings 1.1 Terms and Summary This manual provides important information for Warning indicates an imminently personnel involved with the installation, operation, and hazardous situation which, if not maintenance of this product. Although you may be avoided, could result in death or familiar with this or similar equipment, it is strongly serious injury, and property... -

Page 5: Warning Tags And Labels

Equipment described herein is not designed for and MUST NOT be used for lifting, supporting, or transporting people, or for lifting or supporting loads over people. Equipment described herein should not be used in conjunction with other equipment unless necessary and/or required safety devices applicable to the system, crane, or application are installed by the system designer, system manufacturer, crane manufacturer, installer, or user. - Page 6 Conformance Statement In order to meet requirements of the Crane Manufacturers Association of America (CMAA), the National Electric Code (NEC) and the American National Standards Institute (ANSI/ASME) Harrington components include: Thermal motor protection for all motors. Rubber bumpers. ...

-

Page 7: Technical Information

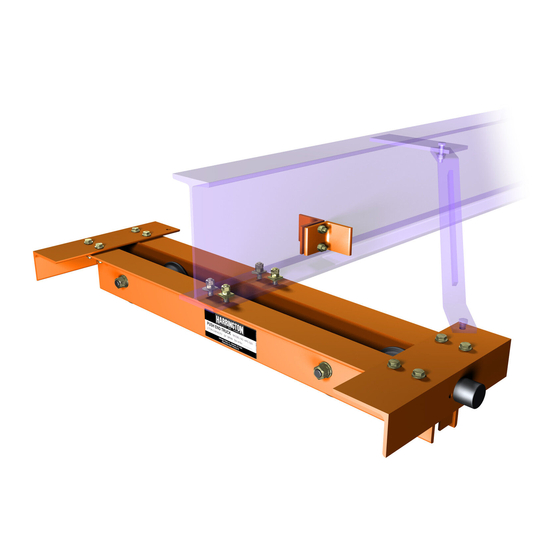

2.0 Technical Information Specifications 2.1.1 Product Codes (a) HPC505 up to ½ Ton capacity (b) HPC510 up to 1 Ton capacity (c) HPC520 up to 2 Ton capacity 2.1.2 Description The HPC500 Series End Truck Kit includes two 4-wheeled end trucks with rubber bumpers, bridge beam end stops, bridge beam fastener hardware, bridge beam assembly drawing, and this Owner’s Manual &... - Page 8 Underhung Top Running Figure 2-1 HPC500 End Truck Dimensions (refer to Table 2-1)

-

Page 9: Part Names

Part Names END TRUCK TOP RUNNING RUNWAY RAIL BRIDGE BEAM BRACE RUNWAY BEAM UNDERHUNG END TRUCK BRACE BRIDGE BEAM Figure 2-2 Part Names – Crane System... - Page 10 UNDERHUNG SWEEP FRAME WHEEL BRACKET B BRACKET A BUMPER TOP RUNNING BRACKET B WHEEL BRACKET A FRAME BUMPER SWEEP Figure 2-3 Part Names – End Truck...

-

Page 11: Pre-Operational Procedure

3.0 Pre - operational Procedures Runway 3.1.1 Crane systems must be intalled on runways that are properly designed, fabricated, installed, and supported. The runway must meet the requirements of CMAA Specification 74. 3.1.2 Read through all steps completely before proceeding with installation. ... - Page 12 Table 3-1 Bridge Beams for a MANUAL or E on an HPC500 Crane LECTRIC OIST Important information about this table: Includes 15% Allowance for Electric Hoist Load Factor. Based on Harrington’s manual chain hoist product. For spans greater than 10 ft., braces between end truck & bridge beam should be used. Cap.

- Page 13 SPAN BEAM FLANGE HOLES (from Fig. 3-1) Figure 3-3 Bridge Beam Web Holes – T UNNING End Stop Installation – This step covers the installation of the end stops onto the bridge beam. 3.2.5 Locate the holes that were installed in the web of the bridge beam (step 3.2.4 above). These are the holes for attaching the end stops to the bridge beam.

-

Page 14: End Trucks

End Trucks 3.3.1 Read through all steps completely before proceeding with installation. 3.3.2 All operations associated with the assembly and installation of the end trucks and/or the crane system should be performed under the supervision of a Qualified Person (see Section 5 for the definition of Qualified Person). - Page 15 FLAT WASHER FLAT WASHER HEX NUT (HPC 505 ONLY) *NOTE: DROP STOP NOT SHOWN FOR CLARITY. WHEEL LOCK FRAME* ASSEMBLY WASHER Figure 3-6 Wheel Assembly Installation Underhung Top Running Figure 3-7 Wheel Mounting Locations Verify “H” Dimension – The “H” dimension is the End Truck Frame Spacing (see Table 2-1 and Figure 3.3.5 2-1).

- Page 16 RUNWAY BEAM FRAME APPROX. APPROX. END BRACKET UNDERHUNG Figure 3-8 Verify “H” Dimension RUNWAY BEAM HEX-HEAD CAP HEX NUT SCREW HEX NUT FLAT WASHER FLAT WASHER FLAT WASHER HEX NUT HEX NUT FLAT WASHER HEX-HEAD RUNWAY RAIL TO P R U N N IN G UNDERHUNG SCREW Figure 3-9 End Truck Assembly &...

- Page 17 Ensure that the “H” dimension is correct as determined in step 3.3.5 above, and tighten the fasteners by applying 75 ft-lb of torque. Top Running – apply the following steps for each end truck: Ensure that the “H” dimension is correct as determined in step 3.3.5 above, and tighten the fasteners by applying 75 ft-lb of torque.

-

Page 18: Pre-Operational Checks And Trial Operation

TRUCK 90° BRIDGE 90° BEAM Figure 3-11 Crane Squareness Pre-operational Checks and Trial Operation Record the end trucks’ Code and Serial No. from the nameplate (see Figure 10-1) in the space 3.4.1 provided on the cover of this manual. 3.4.2 Ensure that the end trucks are properly installed on the runway beams/rails. -

Page 19: Operation

Operation Introduction Specific operation instructions are not provided herein because the HPC500 series end trucks are used in systems not covered by this Owner’s Manual. Nevertheless, operation of systems using the HPC500 end trucks issue – following is important information about operation. is an E XTREMELY MPORTANT... -

Page 20: Inspection

5.0 Inspection General 5.1.1 The inspection instructions herein are limited to the HPC500 Series End Trucks and Harrington- designed HPC500 Cranes, and are based on the use of these products for overhead cranes and monorails as defined by the following standards. ... -

Page 21: Frequent Inspection

Severe service - quarterly Special or Infrequent Service – as recommended by a Qualified Person Frequent Inspection 5.3.1 Use the following as guidance for inspections to be made on a FREQUENT basis. Inspect all functional operating mechanisms for: Proper Operation Proper Adjustment Unusual Sounds... -

Page 22: Occasionally Used End Trucks

Occasionally Used End Trucks and Cranes 5.5.1 End Trucks and cranes that are used infrequently shall be inspected as follows prior to placing in service: Idle More Than 1 Month, Less Than 1 Year: Inspect per FREQUENT Inspection criteria of Section 5.3 above. - Page 23 Table 5-2 Inspections Methods and Criteria Component Item Method Criteria Corrective Action Fasteners must be sufficiently tight. Check tightness Fasteners Refer to torque values listed in Tighten Measure torque Section 3. The surfaces on which the end Wheel Running Clean/remove Visual truck wheels run must be free of oil, Surfaces...

- Page 24 Table 5-3 Wheel Tread Diameter Min. Value for Standard Value Replacement End Truck Code (in) (in) HPC505 3.12 2.97 HPC510 4.00 3.81 HPC520 4.88 4.66...

-

Page 25: Lubrication

6.0 Lubrication HPC500 End Trucks 6.1.1 There are no lubrication requirements for the HPC500 Series End Trucks for the following reasons. The wheel bearings are sealed and permanently lubricated. There are no other components that are lubricated or which require lubrication. Other Equipment 6.2.1 If a hoist/trolley (or some other type of equipment) is used in the system, then perform lubrication of the... -

Page 26: Maintenance & Handling

7.0 Maintenance and Handling General 7.1.1 The HPC500 Series End Truck is designed to be M AINTENANCE If a hoist/trolley (or some other type of equipment) is used in the system, then perform maintenance and handling of the hoist/trolley (or other equipment) in accordance with the manufacturer’s requirements and recommendations. -

Page 27: Troubleshooting

8.0 Troubleshooting Use Table 8-1, “Troubleshooting Guide” below to troubleshoot any problems you may encounter with the HPC500 Series End Truck or Crane. Table 8-1 Troubleshooting Guide Trouble Cause Remedy Make sure the span of the runway system is within the allowable tolerance of CMAA Spec 74. -

Page 28: Warranty

Warranty All products sold by Harrington Hoists, Inc. are warranted to be free from defects in material and workmanship from date of shipment by Harrington for the following periods: 1 year – Electric and Air Powered Hoists (excluding (N)ER2 Enhanced Features Models and EQ/SEQ Models), Powered Trolleys, Powered Tiger Track Jibs and Gantries, Crane Components, Below the Hook Devices, Spare / Replacement Parts 2 years –... -

Page 29: Parts List

10.0 Parts List When ordering Parts, please provide the Code number located on the end truck nameplate (see Figure 10-1 below). Reminder: Per Sections 1.1 and 3.4.1, to aid in ordering Parts and Product Support, record the end trucks’ Code and Serial No. - Page 30 Table 10-1 Parts List for HPC500 Series End Trucks Figure Qty/Pr HPC505 HPC510 HPC520 PART NAME Number 52391 52390 62674 Frame Assembly End Bracket A – Standard Flange Range 62675 End Bracket A – Extended Flange Range 62678 End Bracket B – Standard Flange Range 62676 End Bracket B –...

- Page 31 NOTES...

- Page 32 Harrington Hoists, Inc. Toll Free: 800-233-3010 www.harringtonhoists.com 401 West End Avenue Phone: 717-665-2000 Manheim, PA 17545 Fax: 717-665-2861 HPC500OM-ENG...

Need help?

Do you have a question about the HARRINGTON HPC500 Series and is the answer not in the manual?

Questions and answers