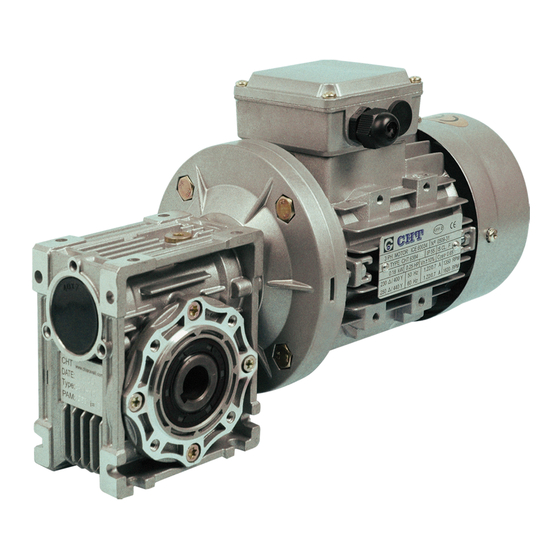

Summary of Contents for Chiaravalli CHM Series

- Page 1 CHM Wormgear Maintenance List Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, Tel. 02261-40970, Fax: 41309, www.stoewer-getriebe.de...

-

Page 2: How To Use This Manual

Safety and commissioning instructions 1 -How To Use This Manual Take attention to the following safety and warning signs for proper understanding and quick reference. Electric Hazard; Can cause severe or fatal injuries. Mechanical Hazard; Can cause severe or fatal injuries. Likely to be Hazardous;... - Page 3 Installing b) Transportation When the goods arrive, first check for any damage. If some damage observed, immediately contact the transport company and inform about the damage. Contact STOEWER for the damage and do not start to install the unit until it is agreed that the damage has no affect of operation.

-

Page 4: Preparing For Installation

Installation Preparing for installation The drive unit must be inspected and may only be installed if no transportation damage or leaks are visible. In particular the radial seals and the sealing caps must be inspected for damage. All bare metal surfaces and shafts of the gear unit are protected against corrosion with oil, grease or corrosion protection agents before shipping. -

Page 5: Installing The Gear Unit

Installation 5- Installing The Gear Unit a) Before you start; - Observe the gear unit for damages of storage or transportation. If any damage please contact Stoewer Antriebstechnik GmbH - Be sure that you have all the equipment necessary for installing like; Spanners, torque tance rings, fixing devices for input and output elements, lubricant, bolt adhe- wrench, shims and dis sive/locktide etc. - Page 6 Lubrication LUBRICATION CHM 025/090 CHM 110/150 CHPC Lubricant Synthetic Mineral Mineral Mineral Synthetic °C ambient -25°C/+50°C -25°C/+50°C -5°C/+40°C -15°C/+25°C -25°C/+50°C VG320 VG320 VG460 VG220 VG320 AGIP TELIUM BLASIA 320 BLASIA 460 BLASIA 220 TELIUM VSF 320 VSF 320 SHELL TIVELA OMALA OMALA OMALA...

- Page 7 Lubrication & Mounting Position Posizioni di montaggio - Positions de montage - Einbauposition - Mounting positions Tappo sfiato Tappo carico Tappo livello Tappo scarico Vent plug Filling plug Level plug Drain plug Bouchon a event Bouchon remplissage Bouchon jauge Bouchon vidange Entlüftungsstopfen Einfüllstopfen Ölstandsstopfen...

- Page 8 Mounting Position CHM / CHM Series The execution determines the mounting position of the first gear in relation to the second gear. If not otherwise specified at the time of order, the group will be supplied in the OBS execution. The placing position refers to the second gear.

-

Page 9: Troubleshooting

Troubleshooting Problemi durante il funzionamento Troubleshooting Se durante le fasi di avviamento o le prime ore di funziona- If any problems should arise when starting the unit or mento sorgessero problemi di vario during its first few hours of operation, contact the after genere contattare il servizio di assistenza post vendita presso sales service dept. - Page 10 Sparepart Table Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, Tel. 02261-40970, Fax: 41309, www.stoewer-getriebe.de...

- Page 11 Sparepart list / Input site Pos Spareparts Housing PAM-Flange Gear unit cover Double ext. PAM worm Double ext. RV worm 01 N Screw DIN 912 02 N Screw DIN 912 03 N Key DIN 6885 04 N Circlip DIN 472 05 N Spacer DIN 06 N Oil Seal DIN 3760 07 N End cap...

- Page 12 Sparepart list / Connections Pos Spareparts Output flange F Torque arm Single output shaft Double output Shaft Saftey cover 01 N Srew DIN 912 02 N Srew DIN 912 03 N Srew DIN 912 04 N Key DIN 6885/1 05 N Key DIN 6885/1 06 N Key DIN 6885/1 07 N Circlip DIN 471 08 N Circlip DIN 471...

- Page 13 Sparepart list / Double Wormgear Pos Spareparts 1 Combination flange 2 Connection shaft Saftey Cover 01 N Srew DIN 931 02 N Srew DIN 931 03 N Srew 04 N Key DIN 6885/1 05 N Key DIN 6885/1 06 N Key DIN 6885/1 07 N Oil seal DIN 3760 08 N O-Ring Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, Tel.

- Page 14 Sparepart list / Wormgear with Pre-Stage Module Pos Spareparts Pre-stage unit casing Cover Low speed shaft Hollow pinion Gear Bush Washer Stop ring 01 N Srew DIN 7991 02 N Srew DIN 931 03 N Srew DIN 931 04 N Srew DIN 916 05 N Nut DIN 934/6 06 N Nut DIN 934/6 07 N Circlip DIN 3760...

- Page 15 Safety and commissioning instructions Safety and commissioning instructions Warning symbols in these instructions The symbols are used in these operating instructions to point out to particular dangers. This symbol refers to a dangerous situation which can cause fatal or serious injuries or considerable damage to property.

-

Page 16: Electrical Connection

Safety and commissioning instructions Installation Take care of an even ground, suitable fastening of feet or flange and an exact alignment for direct coupling. Avoid that structure–dependent natural frequencies occur within the rotary frequency and the double mains fre- quency. - Page 17 Installation ans commissioning Installation and commissioning A most careful mounting and alignment of the motors on an absolutely even surface is impera- tive to avoid distortions when the screws are being tightened. For machines which are to be coupled it must be paid attention to a careful alignment.

- Page 18 Installation ans commissioning Connection, insulation resistance Connection must only be made by an expert and in accordance with the valid safety regulations. The relevant installation– and operating instructions as well as national and international rules have to be observed.

-

Page 19: Check Before Commissioning

Installation ans commissioning Change of rotational direction: For DOL (direct on–line) starting and in pole–changing motors with separate windings the di- rection of rotation can be reversed by exchanging two mains conductors on the terminal board of the motor. For motors with star/delta starting and pole–changing motors with Dahlander winding, 2 (two) mains conductors at the input to the motor switch have to be exchanged. - Page 20 Installation ans commissioning Motorconnection Anschließen des Motors All work is only allowed to be done by qualified personnel with the low voltage motor and driven machine at stand still, electrically dead and locked against restart. The design acc. DIN VDE 0530 Teil 8. Schaltbild / Wiring diagram Käfigläufer mit einer Käfigläufer mit einer...

- Page 21 Installation ans commissioning Maximum radial force (FR) ( N) X1/2 Xmax Größe Polzahl Radiallasten Permissible radial loads for horizontal and vertical The following table give the permissible radial forces in Newton, assuming zero axial force ** force" and standard ball bearings. In case of higher radial force than given in the table an enforced bearing should be ordered.

- Page 22 Axial loads Inbetriebnahme Maximum radial force (FR) ( N) Größe Polzahl F zug F zug F druck F druck Axiallasten Permissible axial loads for horizontal and vertical The following table gives the permissible axial forces in Newton, assuming radial force**. In this case motor should be ordered with standard ball bearings. case of higher axial force than given in the table an angular contact bearing be ordered.

-

Page 23: Motor Connection

Motor connection connection drwaings for brakemotor connection drwaings for brakemotor Die Montage und Inbetriebnahme darf nur vom geschulten Fachpersonal durchgeführt werden Das Getriebe und der Motor müssen beide getrennt geerdet werden. Faststop (380 V) Normal stop ( 380 V ) R S T R S T Bremsspule... - Page 24 Brakemotors “AC” TYPE BRAKE BREMSENTYP “AC” This is an electromechnical spring brake powered by alternating Hierbei handelt es sich um eine elektromechanische Federbremse mit current. It serves to stop rotation of the drive shaft. Wechselstromantrieb. Ihr Zweck besteht darin, die Drehung einer Motorwelle The main characteristics are: anzuhalten.

- Page 25 Brakemotors “K” TYPE BRAKE BREMSENTYP “K” Diese elektromechanische Federbremse wird mit Gleichstrom betrieben. This is an electromechnical spring brake powered with direct current. Ihr Zweck besteht darin, die Drehung einer Motorwelle anzuhalten, sobald It serves to stop rotation of the drive shaft as soon as the power die elektrische Stromversorgung ausfällt.

- Page 26 Brakemotors BREMSENTYP “S” “S” TYPE BRAKE This is an electromechnical spring brake powered with direct current. Diese elektromechanische Federbremse wird mit Gleichstrom betrieben. Ihr Zweck besteht darin, die Drehung einer Motorwelle anzuhalten, sobald It serves to stop rotation of the drive shaft as soon as the power supply is cut off.

- Page 27 Brakemotors EINSTELLUNG DER BREMSE BRAKE REGULATION The measurement of the gap must be checked occasionally because the disk Von Zeit zu Zeit muss die Abmessung des Eisenspalts üfberprüft werden, lining is subject to wear. da sich der Bremsbelag der Bremsscheibe abnutzt. Wenn dieser Wert erhöht If this gap is great the electromagnet is heated further and the minimum ist, wärmt sich der Elektromagnet stärker auf, und die für die Anziehung des voltage needed to engage the armature can increase to the point where the...

- Page 28 RETARDER DECELLERATOR BREMSE C.A. C.A. BRAKE 1 - Wellengehäuse 2 - Keil 3 - Lagerschild 4 - Ausgleichsspannring 5 - Lager 6 - Motorwelle 7 - Läufer 8 - gewickelter Stator 9 - Gehäuse 10 - Öfnung Kabeleinführung 11 - Klemmenbrett für Netzanschluss 26 26 12 - Dichtung IP55 13 - Klemmendose - Unterbau...

- Page 29 RETARDER DECELLERATOR 1 - Wellengehäuse 2 - Keil 3 - Lagerschild 4 - Ausgleichsspannring 5 - Lager 6 - Motorwelle 7 - Läufer 8 - gewickelter Stator 9 - Gehäuse 10 - Öfnung Kabeleinführung 11 - Klemmenbrett für Netzanschluss 26 26 12 - Dichtung IP55 13 - Klemmendose - Unterbau 14 - Dichtung IP65...

- Page 30 BREMSE C.A. C.A. BRAKE 26 26 26 BREMSE C.C. C.C. BRAKE Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, Tel. 02261-40970, Fax: 41309, www.stoewer-getriebe.de...

-

Page 31: Faults And Remedies

Faults and remedies Faults and remedies Fault Possible causes Remedy Bearing is too hot Bearing noise*) Motor runs unevenly Too much grease in bearing Remove excess grease Bearing dirty Replace bearing Belt tension too high Reduce belt tension Coupling forces are pulling or Realign motor, correct coupling pushing... - Page 32 Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, Tel. 02261-40970, Fax: 41309, www.stoewer-getriebe.de...

Need help?

Do you have a question about the CHM Series and is the answer not in the manual?

Questions and answers