Summary of Contents for Rodwell GEMINI-MP25 with SmartCard

- Page 1 Operators Manual GEMINI - MP25 with SmartCard Serial number 2140 Rodwell Scientific Instruments, Bentalls, Basildon, Essex. England. Tel: + 44 (0) 1268 286646 Fax: +44 (0) 1268 287799 Manual issue 14-12-10...

-

Page 2: Table Of Contents

CONTENTS SECTION INTRODUCTION---------------------------------------------------- INSTALLATION ---------------------------------------------------- MACHINE OPERATION & MP25 CONTROLS AND INDICATORS----------------------- NORMAL OPERATION PROCEDURE QUICK GUIDE -- BASIC FAULT FINDING----------------------------------------- ROUTINE MAINTENANCE-------------------------------------- TECHNICAL INFORMATION------------------------------------ RISK ASSESSMENT AND SAFETY----------------------------- USER REPONSIBILITES------------------------------------------- A GUIDE TO THE PLANNING AND IMPLEMENTATION OF YOUR HEALTH AND SAFETY CONTROL MEASURES ---------------------------------------------------------- DISPOSAL –... -

Page 3: Introduction

80˚C and a means of breaking the pressure seal with the door restrained. The development of the Rodwell ‘GEMINI’ has resulted in a unit that is both easy to use and service. -

Page 4: Installation

(A water treatment device can be supplied and fitted by Rodwell Scientific Instruments). Sodium Chloride within the water supply should not exceed a level greater than 30 parts per million. Failure to comply may result in damage to the autoclave and the invalidation of any warranty. - Page 5 If condense collector vessel is used then this is not suitable for Instrument cycles or extended time Free Steaming cycles. A portable condense collector should always be positioned in a safe place. As an option an autoclave mounted fan cooled condense outlet can be supplied. INITIAL CHECK OPERATION PROCEDURE ...

-

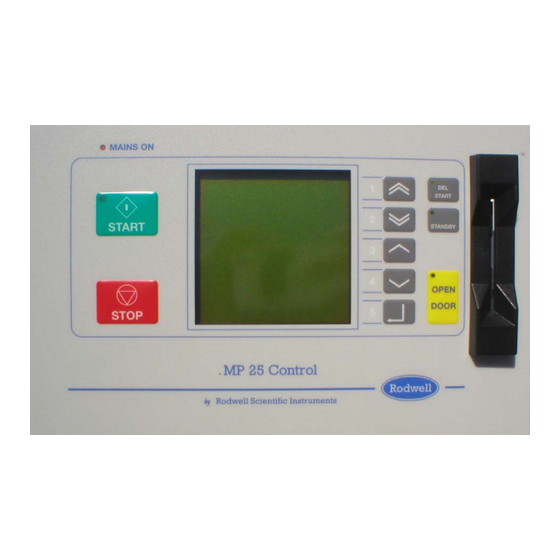

Page 6: Machine Operation

SECTION THREE MACHINE OPERATION Operating Instructions When the System is first switched on the display will show the welcome message. This message also contains the current time and date, check that it is correct. After about ten seconds the welcome message will be replaced by the current system status on the top line with the chamber and load temperatures below this, some machines will also display the pressure. - Page 7 Operating the machine Select prog The machine should be showing the screen. If the door is not open press the door open button to release the door. If it is safe to open the door then the door open indicator door is released will light and the display shows .

- Page 8 If any other messages appear then press the door open button and carry out the required operation before pushing the start button again. Pressing the door open or the stop button will stop the process cycle until the temperature reaches 80C. Once the temperature reaches this figure the process cannot be stopped other than by use of the stop button.

- Page 9 The machine will go through an automatic test process and if it is fitted with autofill, will fill with water. Provided all is correct the machine will display the current time and the message 'Waiting for start'. The machine will start when the preset time is reached. If the delayed start is pressed accidentally, press it again to turn the function off.

- Page 10 minutes for the machine to heat up then there is no point in selecting values below 10 minutes). Sterilise time: Set the required sterilise time in hours and minutes Sterilise temperature: Set the required temperature Ramp down time: This operates in a similar manner to the Ramp up time allowing the machine to cool sensitive loads slowly.

- Page 11 Set sounder Volume: Press the up and down buttons to set the required volume level for the sounder and press enter to save this and return to the menu. Note that the volume control effects only the beep when the buttons are pressed and the cycle complete alert, if the machine develops a fault the alarm will be at a louder level.

- Page 12 If the smart card function has been switched off or you require specific card functions contact Rodwell Scientific or your machine supplier for further details. Supervisors Card for Programming of MP25.

- Page 13 Rodwell Scientific have tested and configured the ‘memory stick’ supplied to operate with the MP25 controller and to provide ease of operation. Rodwell scientific do not advise the use of other memory devices with their controllers. Once files are backed up to a secure device...

-

Page 14: Normal Operation Procedure Quick Guide

SECTION FOUR ‘NORMAL’ OPERATING PROCEDURE QUICK GUIDE With autoclave door open ‘LOAD’ Chamber with items to be sterilised and place the Load temperature probe into centre of the machine, into the largest load or into a suitable load simulator as best suits the application ... -

Page 15: Basic Fault Finding

SECTION FIVE BASIC FAULT FINDING The sterilising cycle is continually monitored to ensure correct progress. Should the system fail to sterilise for any reason or should a fault develop that could prevent correct operation the machine will lock out. The screen messages will help you or an engineer to determine the cause of the fault. - Page 16 Thermal overheat There is a thermal safety switch fitted to the boiler. If this switch operates then this message is displayed. You will need to call a service engineer to reset this safety device. Some conditions can occur when attempting to open the door. In order to maintain safety and prevent possible damage to the machine there are a number of conditions that prevent the door being opened.

- Page 17 FAULT FINDING CHART FAULT CAUSE REMEDY ============================================================= No mains power Switch on/Check fuses Door will not open Temperature too Allow more time high. to cool. Malfunction of Safety Locks Release (Call Service Department) ============================================================= No power supply. Check fuses. Push reset button Cycle fails to start Door not closed.

-

Page 18: Routine Maintenance

SECTION SIX ROUTINE MAINTENANCE Replacing printer paper roll Access to the printer for changing the paper roll is provided by a hinged front panel. The spring-loaded catch on the left hand side of the printer front panel should be depressed to release the front panel. - Page 19 Main door release catch Figure 1 Printer release catch Correct paper path Figure 2 Figure 3 Ribbon above paper Feed paper between ribbon and cartridge Figure 4...

- Page 20 Daily Maintenance by Operator Ensure that all safety interlocks are operating correctly. In the event of failure DO NOT use the autoclave. Call a person in authority. Check that the Load temperature probe is not damaged or defective before each cycle. (If the probe is damaged the autoclave must NOT be used, Call a person in authority).

- Page 21 Your maintenance engineers should be fully conversant with the function of the Autoclave, so that notwithstanding any service contract, emergency maintenance can be affected if necessary. In the event of a major breakdown, the Rodwell Scientific Instrument service engineer (or their recognised Distributor service engineer for your area) should be called A log book should be kept adjacent to each Autoclave.

-

Page 22: Technical Information

SECTION SEVEN TECHNICAL INFORMATION MODEL: GEMINI 316 AUTOCLAVE WEIGHT: 740 kg. SIZE: 142cm D. x 70 cm W. x 198 cm H. SAFE DESIGN OPERATING LIMITS. Maximum Working Temp. 138° C. Minimum Working Temp. 7° C. Maximum Hydraulic Pressure 4.14 Bar. Maximum Working Pressure 2.26 Bar. -

Page 23: Risk Assessment And Safety

SECTION EIGHT RISK ASSESSMENT AND SAFETY HAZARDS COMMENTS Burns and Scolds from Liquid Loads. Protective Clothing must be worn. Back injury through loading and unloading Use Loading Hoist or Loading Trolley. Burns and Scolds from opening the autoclave Locks fitted. However care should always be before cycle complete. - Page 24 SECTION NINE USERS RESPONSIBILITIES The User is responsible for ensuring that • the load contents will be compatible with the materials used to construct this vessel • the chamber is free from stress corrosion cracking, this is foreseen by the use of sodium chlorides, from the load or from the water used in filling the vessel.

-

Page 25: A Guide To The Planning And Implementation Of Your Health And Safety Control Measures

Are the following Control Measures in place? • Method Statements. • Autoclave Risk Assessment. • Operator Risk Assessment • Periodic Maintenance, by an authorised Rodwell Scientific Engineer. • Operator Training. • Pressure Vessel annual Inspection. • Autoclave Log Book for Daily Records. •... -

Page 26: Disposal - Caring For The Environment

SECTION ELEVEN DISPOSAL – CARING FOR THE ENVIRONMENT Please consider the environment when disposing of your Autoclave. Disposal of the Autoclave should be carried out by a professional disposal company, after decontamination of any bacteriological or microbiological waste. A clearance note must be issued by the end user. -

Page 27: Disclaimer

Whilst every effort has been made to ensure the information in this manual is correct and relevant. Rodwell Scientific Instruments and its associated companies will not accept any liability for errors omissions or inaccuracies. - Page 28 SECTION THIRTEEN Recommended Gemini spare parts for 2 years 2 off 312-0009 Door Seal 6 off 315-0201 Heater Element (277V) 4 off 309 - 5038 Heater Glands 6 off 836 - 0180 PT100 Black Probes 2 off 820 - 0067 Bolt Safety Switch 2 off 309 - 0763...

-

Page 29: Service Record

Always use manufacturers specified spare parts only. Service 1 Date: Service 2 Date: Machine cycle count: Machine cycle count: Engineer’s Name: Engineer’s Name: Company Name: Company Name: Rodwell certification No.: Rodwell certification No.: Certification expiry date: Certification expiry date: Comments: Comments: Signature: Signature: Service 3 Date:... - Page 30 Service 9 Date: Service 10 Date: Machine cycle count: Engineer’s Name: Machine cycle count: Company Name: Engineer’s Name: Rodwell certification No.: Company Name: Certification expiry date: Rodwell certification No.: Comments: Certification expiry date: Comments: Signature: Service 11 Date: Service 12 Date:...

- Page 31 HSE Guidance Note PM 73 Safety at autoclaves Health & from the Safety Health and Safety Executive of vertical autoclaves are secured in the pressure tight position Plant and Machinery Series PM73 (August 1990) by bolts, swing bolts or swivelling locking stirrups, or by a mechanism which permits rapid opening, usually referred to as This Guidance Note incorporates relevant parts of 'quick-opening doors';...

- Page 32 on the pressure gauge but which, acting over the surface area vessels be used to establish minimum requirements. of the door, may exert considerable force. For example a Recognised Standards should be used for the pressure of 0.1 bar acting on a door of 2 m diameter would design and construction of autoclaves.

- Page 33 arrangement incorporating a temperature sensing device located in that part of the vessel which is expected to remain at the highest temperature at the end of the cycle. Autoclaves with quick‐opening doors Written procedures for operating the door securing mechanism should be permanently and prominently displayed at or near the operating point.

- Page 34 Adjustment they could allow premature operation of a following sequence with dangerous consequences. Useful guidance on the principles of application of interlocking Common drain, blown-down and transfer lines devices is given in BS5304: Safety of machinery. A properly trained and authorised person should Independent drain lines and blow-down lines should be check at regular intervals that the interlocks function correctly provided.

-

Page 35: Appendix 1 Hse Guidance Note

Periodic examination pressure, including air and hot water kept above its boiling point, at a pressure greater than 0.5 bar. In addition 'relevant fluid' covers steam at any pressure. All autoclaves should be examined at least once in every 26 months by a person who is competent to assess This Guidance Note gives advice which is their suitability for continued safe use.

Need help?

Do you have a question about the GEMINI-MP25 with SmartCard and is the answer not in the manual?

Questions and answers