Table of Contents

Advertisement

Quick Links

Owners Manual

Head Office:

PO Box 2018

Hilton Highway, Washdyke

Timaru, New Zealand

Telephone (03) 688 2029

Facsimile (03) 688 2821

920 Maxi-Till

Cultivator

Australian Branch

4B Silverton Close

Laverton North 3026

Melbourne, Australia

Telephone (03) 9314-9666

Facsimile (03) 9314-6810

Pt. No. 67202

Issue 0806

Advertisement

Table of Contents

Summary of Contents for Duncan Maxi-Till 920

- Page 1 Owners Manual 920 Maxi-Till Cultivator Head Office: Australian Branch PO Box 2018 4B Silverton Close Hilton Highway, Washdyke Laverton North 3026 Timaru, New Zealand Melbourne, Australia Telephone (03) 688 2029 Telephone (03) 9314-9666 Facsimile (03) 688 2821 Facsimile (03) 9314-6810 Pt.

-

Page 3: Table Of Contents

Contents 920 Maxi-Till Cultivator Page Introduction ....... Acquisition & Warranty . -

Page 4: Introduction

The Owner’s Manual without notification. Your new Duncan Maxi-Till will give long and efficient service if The Company will not be given normal care and operated properly. responsible for any damage or consequential loss arising out of This owner’s manual is provided so that you can become... -

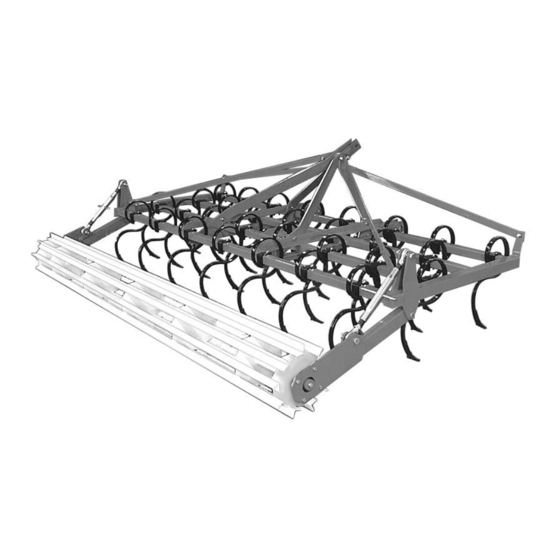

Page 5: Description Of Machine

Description of Machine The Duncan 920 Maxi-Till Cultivator is a strong, durable low maintenance implement. The ‘S’ tine concept is undeniably here to stay with its savings in fuel and time. The crumbler size and placement has been developed through field work to give the farmer the maximum benefit from this concept. - Page 6 ATTENTION On the machine important safety information is indicated by these symbols. These highlight general safety aspects in regard to the machine rather than specific hazards. Do not ride or allow passengers on the machine. Under no circumstances are passengers to be permitted on the machine while it is in operation or being transported.

-

Page 7: Safety - General

SAFETY - General This section of the manual offers general guidelines N.B. Throughout this for the safe operation of machinery. It does not replace manual important safety local safety regulations. These guidelines were current at information is indicated the time of publication, but may be superseded by later regulations. - Page 8 SAFETY - General (continued) Appropriate Dress Wear close fitting clothing and avoid rings or other forms of jewellery which could become caught in the machinery. People with long hair must have it securely fixed and confined close to the head. Refer to local safety standards for protective clothing and recommended safety equipment.

-

Page 9: Handle Agricultural Chemicals Safely

SAFETY -General (continued) Handle Agricultural Chemicals Safely All farm chemicals should be stored, used, handled and disposed of safely and in accordance with the supplier’s/manufacturer’s recommendations. Read the product label before using, noting any warnings or special cautions, including any protective clothing or equipment that may be required, ie. -

Page 10: Practice Safe Maintenance

SAFETY - General (continued) Practise Safe Maintenance Keep the machine in safe working condition. Routine maintenance and regular servicing will help reduce risks and prolong the life of the machine. General Maintenance Accidents occur most frequently during servicing and repair. The following general rules must be followed when maintaining or working with machinery: •... -

Page 11: Hazard Points On The Maxi-Till

SAFETY - Machine Specific This section gives specific guidelines for safe operation of the Maxi-Till. These guidelines were current at the time of publication but may be superseded by later circumstances. They do not necessarily cover every possible hazard and must be read with the SAFETY - General section (Pages 4-8). - Page 12 Transport Raise the three point linkage as high as possible to maximise ground clearance. Ensure that ground clearance is sufficient. Ensure that all linkage pins and security clips are fitted and operate correctly. Ensure lighting and oversize warning requirements meet recommendations published by the Land Transport Authority or equivalent.

- Page 13 920 Maxi-Till Cultivator Operator Notes Pt. No. 67202 Issue 0806...

-

Page 14: General Safety & Accident Prevention

Maintenance & Care General Safety and Accident Prevention Make sure that if the tractor remains attached to the drill that the ignition key is removed. During maintenance the implement should be supported in such a manner that if hydraulic failure was to occur the machine would still be adequately supported. -

Page 15: Maintenance Schedule

Maintenance & Care (Continued) Your new Maxi-Till Cultivator will give long and efficient service if given normal care and maintained properly. Maintenance Schedule Bolted Connections All bolted connections on the machine should be checked after the first use (or 50Ha) and retightened if necessary. Thereafter, check the connections at regular intervals to minimise equipment damage and accidents resulting from loosening of the fasteners. - Page 16 920 Maxi-Till Cultivator Maintenance Notes...

- Page 17 Parts List 920 Maxi-Till Cultivator Head Office: Australian Branch PO Box 2018 4B Silverton Close Hilton Highway, Washdyke Laverton North 3026 Timaru, New Zealand Melbourne, Australia Telephone (03) 688 2029 Telephone (03) 9314-9666 Facsimile (03) 688 2821 Facsimile (03) 9314-6810 Pt.

- Page 18 Bottom Link Detail 37 38 Top Link Detail 13 32 RH Crumbler Bearing Adjustable LH Crumbler Arm Bearing Detail 22 20 Endcap & Spacer Endcap Only When When Arm Retracted Arm Extended...

- Page 19 920 Maxi-Till Cultivator Complete Assembly Item Part No. Description Qty. Refer Below Main Frame Assembly 43061 FY 508M Bearing Housing Refer P 4 Triple K Tine Complete with K25 Point (Refer Table for Quantities) 43145 YAR208-108-2F Y Bearing 1 ” Refer P 4 Tine Clamp (Refer Table for Quantities)

- Page 20 920 Maxi-Till Cultivator S Tine Assembly Item Part No. Description Qty. 43125 Triple K Tine Complete with K25 Point 43130 K25 x 5mm Point Only 4920075 Standard Maxi-Till Tine Clamp 43131 K45 100mm Row Crop Point (Optional) 45444 M12 x 90 Class 4.6 Zinc Plated Bolt 45131 M12 Class 8.8 Zinc Plated Hex Nut 45200...

Need help?

Do you have a question about the Maxi-Till 920 and is the answer not in the manual?

Questions and answers