Table of Contents

Advertisement

Quick Links

Installation, Operation, and Maintenance Manual

Upon receiving unit, check for any interior and exterior damage, and if found, report it immediately

to the carrier. Also check that all accessory items are accounted for and are damage free. Turn the

blower wheel by hand to verify free rotation. Check the damper (if supplied) for free operation.

Installation of this unit should only be performed by a qualified professional who has read and

understands these instructions and is familiar with proper safety precautions. Improper

installation poses serious risk of injury due to electric shock, contact with rotating equipment,

and other potential hazards. Read this manual thoroughly before installing or servicing this

equipment. ALWAYS disconnect power prior to working on unit.

Save these instructions: This document is the property of the owner of this equipment and is required for

future maintenance. Leave this document with the owner when installation or service is complete.

RECEIVING AND INSPECTION

WARNING!!

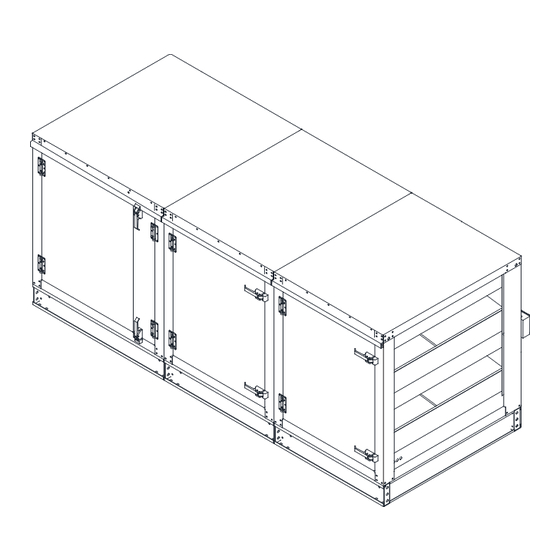

Pollution Control Unit

A0011036

June 2020 Rev. 42

Advertisement

Table of Contents

Summary of Contents for ThermoTek PCU

- Page 1 Pollution Control Unit Installation, Operation, and Maintenance Manual RECEIVING AND INSPECTION Upon receiving unit, check for any interior and exterior damage, and if found, report it immediately to the carrier. Also check that all accessory items are accounted for and are damage free. Turn the blower wheel by hand to verify free rotation.

-

Page 2: Table Of Contents

Installing Module in Field ........................9 Gasketing ............................9 Equipment Rails ..........................10 Air Pressure Switch Option .........................11 Advanced Filter Monitoring Option ...................... 12 PCU AFM LCD Menus ........................13 Electrostatic Precipitator (ESP) Module ....................14 Self-Cleaning ESP ..........................15 LCD Menu Tree ...........................17 Fire System ............................18 Climate Controlled Utility Cabinet .......................19... -

Page 3: Warranty

WARRANTY This equipment is warranted to be free from defects in materials and workmanship, under normal use and service, for a period of 2-years from date of shipment. This warranty shall not apply if: 1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation instructions shipped with the product. -

Page 4: Listings

This will ensure that the system maintains its integrity against fire conditions in the future. The manufacturer of this PCU cannot be responsible for grease duct systems that are not properly maintained or have been subjected to one or more grease fires. -

Page 5: Electrical

ELECTRICAL WARNING!! Disconnect power before installing or servicing unit. High voltage electrical input is needed for this equipment. A qualified electrician should perform this work. Before connecting power to the control, read and understand the entire section of this document. As-built wiring diagrams are furnished with each unit by the factory and are attached to the control module’s door or provided with paperwork packet. -

Page 6: Installation

5. Support unit above ground or at roof level high enough to prevent precipitation from being drawn into unit. 6. The PCU is designed to operate in a negative pressure environment. Be sure to install the PCU between the exhaust fan and hoods. This will also keep the fan cleaner during operation. -

Page 7: Joint Sealant

Joint Sealant The joint sealant used to seal all joint assemblies is a 3M product. 3M Fire Barrier 2000 + Silicone Sealant is a ready-to-use, gun-grade, one-component silicone elastomer that cures upon exposure to atmospheric humidity to form a flexible seal. 3M Fire Barrier 2000 + Silicone Sealant, when installed properly, will control the spread of fire before, during and after exposure to open flames. -

Page 8: Ductwork

When the is used in commercial grease ductwork, the ductwork connections must be FULLY WELDED to the inlet and discharge of the PCU. Ductwork must be listed or installed in accordance with the IMC. When the PCU is installed in grease rated ductwork, the clearance to combustible surfaces to this unit is 18 inches. -

Page 9: Installing Module In Field

QUANTITY (2) ON EACH SIDE Gasketing There are two types of gasket used in sealing the PCU, refer to Table 3. The orange gasket is used for weatherproofing the exterior seams between modules. It is rated at 450° F and has a PSA (Pressure Sensitive Adhesive) backing. -

Page 10: Equipment Rails

The unit should be installed on a curb and/or rail elevated not less than 14 inches above any roof surface. Secure PCU to rails through vertical portion of the PCU base assembly flange using 1/4”-14 x 1.5” long self-drilling screws with a minimum of 4 screws per rail. Shims may be required depending upon equipment rail installation and roofing material. -

Page 11: Air Pressure Switch Option

Air Pressure Switch Option Switches are preset from plant to 0.15” w.c. above the internal static pressure of the PCU with clean filters. An air pressure switch, refer to Figure 7, is located in the downstream filter module. Route wiring from hood control panel to PCU using 1/2” conduit through quick seal located near lower right area of filter module containing switch. -

Page 12: Advanced Filter Monitoring Option

PCU assembly. The following chart shows the port connections used for different PCU configurations. PORT 7 is used only if the PCU assembly has a blower installed. The unused ports remain exposed to the space in the cabinet. Port 8 (Atmospheric Port) is used to measure ambient pressure, external to the PCU. -

Page 13: Pcu Afm Lcd Menus

PCU assembly is entered followed by the filter type for each module. - PCU Number - The number for this PCU will be displayed in reverse video and is selected using the board buttons. This number allows for up to 8 PCUs to exist on one Modbus network. -

Page 14: Electrostatic Precipitator (Esp) Module

PCU door. If there are multiple cells, springs are located between cells. All spring contacts are placed on the front... -

Page 15: Self-Cleaning Esp

If the PCU is mounted outdoors, heat tape must be applied to all external piping for the ESP Self- Cleaning System (SCS). If a self-draining SCS package is used, heat tape is not necessary. - Page 16 Table 5, Table 6, and Table 7 are based on the self-cleaning ESP minimum operating pressure of 20 psi. 0.44 Total Flowrate = K Factor * Pressure Table 5 - Self-Cleaning Water Consumption Based on PCU Size in GPM # of ESP Modules PCU Size 1 Module...

-

Page 17: Lcd Menu Tree

PRESS ANY KEY ENTER PIN CAL. COMPLETE CALIBRATION (1234) PRESS ANY KEY ENTER PIN MODULE # CONFIGURATION CFG PCU MODULES MODULE COUNT 1-5 FILTER CONFIGS. SAVED (5678) FILTER TYPE RANGE: 1-8 PCU # SAVED PCU NUMBER DEFAULT: 1 PRESS ANY KEY... -

Page 18: Fire System

The water or chemical agent used in the fire system can cause the filters to fail prematurely. In the event that a fire occurs in the ductwork leading to the PCU or inside the PCU, the following must be completed. -

Page 19: Climate Controlled Utility Cabinet

Climate Controlled Utility Cabinet For outdoor installations, a climate controlled cabinet is available to house the fire system, refer to Figure 14. This box contains a heater, an exhaust fan, and thermostats to control the temperature inside the cabinet. The Utility Cabinet thermostats come preset to heat below 40°F and cool above 90°F. The climate controlled cabinet requires a dedicated 15 amp, 60 Hz, 115 volt, single phase electrical service. -

Page 20: Bolted Door Design

Last Module OPERATION Prior to starting up or operating the PCU, check all fasteners for tightness. In particular, check the module connection seal and the door seals. With power to the fan OFF, check the airflow direction of the filters as they must match the label on the filter. -

Page 21: Troubleshooting

Troubleshooting Table 8 and Table 9 lists causes and corrective actions for possible problems with the Pollution Control Units (PCU), Electrostatic Precipitator (ESP), and the fan attached to the unit. Review these lists prior to consulting manufacturer. Table 8 - PCU/Fan Troubleshooting Chart... - Page 22 Verify conical springs are installed on the front side of all cells. Check that the cell spring contacts align with the contacts on the PCU door. PCU is not calibrated Calibrate the unit. Fire Scenario If a fire is not present, check wiring.

-

Page 23: Pcuafm Faults

PCUAFM Faults NOTE: In order to prevent erroneous issuing of fault conditions, the monitoring system takes several minutes to issue a fault. Faults will not be detected if PCU is running outside normal hood operating conditions. Table 10 lists causes and corrective actions for possible faults shown on the LCD screen with the PCU. -

Page 24: Maintenance

MAINTENANCE To guarantee trouble free operation of this PCU, the manufacturer suggests following these guidelines. Most problems associated with PCU failures are directly related to poor service and maintenance such as not replacing or cleaning filters. Please record any maintenance or service performed on this unit in the documentation section located at the end of this manual. - Page 25 WARNING: Filter part numbers outlined in Table 11 through Table 15 are for use in the PCU. The use of any other filters will VOID the warranty, and affect unit performance. Table 11 - ESP Cell and Pre/Post-Filter Details Pre-Filter/Post-Filter...

-

Page 26: 2-Weeks After Startup

2. Record inspection and cleaning, keep a maintenance log with unit. 3. ESP cell(s) must be removed from the PCU every 3 months. Clean the cell(s) in warm soapy water. When re-installing cell(s), be sure to install with the airflow in the correct direction as indicated on the cell. -

Page 27: Start-Up And Maintenance Documentation

Fax Number Fax Number Contact Contact Purchase Date Start-Up Date PCU Information Reference the start-up procedure in this manual to complete this section. Name Plate and Unit Information Model Number Serial Number Pressure Switch Set Point Advanced Filter Pressure Monitoring Information... -

Page 28: Cleaning & Maintenance Record

Cleaning & Maintenance Record Date Service Performed As a result of our dedication to constant improvements and quality, the MANUFACTURER reserves the right to update specifications without notice. Please refer to MANUFACTURER’S website for up to date documentation. Scan QR Code for Online Manual Factory Service Department | Phone: 1-866-784-6900 | Fax: 1-919-516-8710...

Need help?

Do you have a question about the PCU and is the answer not in the manual?

Questions and answers