Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Impacts Dustcom 4025

- Page 1 Operating Manual Impacts Filter-Unit DC4025...

- Page 2 DC4025 Bedienungsanleitung/Operating Manual Technische Daten/Technical Data Chapter 1 1.1 Rating PAGE: 1.2 Unit – specifications PAGE: 1.3 Operative range and correct usage PAGE: 1.4 Stand-by power supply ( generator) PAGE: 1.5 Advice for operators PAGE:...

- Page 3 Bedienungsanleitung/Operating Manual DC4025 Technische Daten/Technical Data 1.1 Rating Machine: IMPACTS FILTERUNIT Maschinen-Type : DC4025 Manufacturer: IMPACTS GmbH Zöllnerstr. 7 D-51105 Overath 1.2 Unit – specifications MACHINE DESIGNATION: DC4025 MACHINESERIES: FILTER TRACTIONDRIVE: MANUELL PERFORMANCE: up to 1400m³/h FILTRATION AREA: 44 m²...

- Page 4 This specific filter unit has been designed to vacuum dry dust .The dust collector DC4025 is exclusively designed to be used with IMPACTS machines. It is only allowed to vacuum dry dust. The manufacturer will not be liable for damage resulting from such incorrect usage.

- Page 5 Bedienungsanleitung/Operating Manual DC4025 Technische Daten/Technical Data 1.5 Advices for operators During the operation of the DC 4025 in combination with other equipment it may be possible to exceed the acceptable noice level of 85 dB(A). This is dependend on the different locations and the local circumstances.

- Page 7 DC4025 Operating Manual Safety Advices Chapter 2 2.0 Explanation of warnings and symbols PAGE: 2.1 Organisationel measures PAGE: 2.2 Personnel selection and qualification PAGE: 2.3 Safety precautions applicable to PAGE: different operating conditions 2.4 Repair work , maintenance activities, PAGE: and default repair on the job side 2.5 Definition of the Safety off position PAGE:...

- Page 8 Operating Manual DC4025 Safety Instructions 2.0 Warnings and symbols The following denominations and symbols are used in the Operating Instructions to highlight areas of particular importance: Symbol of operational safety. This symbol will be shown in these Operating Instructions next to all safety precautions that are to be taken in order to ensure prevention to life and injury.

- Page 9 DC4025 Operating Manual Safety Advices Warning against dangerous voltages. Indications relating to protective devices of electrical equipment. Indications where consultation with manufacturer is necessary Instructions relating to periodical checks Reference to important instructions contained in the Operating Instructions...

- Page 10 Operating Manual DC4025 Safety Instructions 2.1 Organisational measures The Oprerating Instructions are to be kept near the location where the filter is located and must be reachable all the time! In addition to the Operating Instructions general and legal regulations regarding accident prevention and environmental protection must be with and indicated every time.! Such duties may for example relate to the handling of hazardous substances or to the provision and wearing of personal protection...

- Page 11 DC4025 Operating Manual Safety Advices If safety-critical changes occur to the filter or its performance, the filter must be shut down immediately! The cause of the fault has to be established immediately and has to be repaired bevor starting the work again.

- Page 12 Operating Manual DC4025 Safety Instructions Specify clearly the operator. Define his responsibilities also regarding to traffic safety regulations and empower him to decline instructions from third parties which are not complying with the safety requirements. Personnel being trained or made acquainted with the equipment may onlyn be deployed under constant supervision of an experienced person.

- Page 13 DC4025 Operating Manual Safety Advices Default must be rectified immediately! Start up and switch off operations and control devices have to be handle in accordance with the Operating Instructions. All persons in the proximity of the filter must wear safety glasses with lateral protection as well as safety shoes.

- Page 14 Operating Manual DC4025 Safety Instructions Before starting any maintenance or repair work the operator of the filter has to be informed about it. During all work related to the use, the re-erection or the adjustment of the filter and of the safety devices as well as inspection, maintenance and repair, the start up and shut off procedures have to be done in accordance with the Operating Instructions.

- Page 15 DC4025 Operating Manual Safety Advices 2.5 Definition of the safety off position Definition: The safety off position is the position of the filter when it cannot generate any hazard. Putting the filter in the safety off position means: Switch off the machine that’s connected to the dust collector. Switch off the dust collector.

- Page 16 Call a skilled electrician or the IMPACTS customer service. If work on life parts is necessary, a second person must be deployed who can pull out the plug in an emergency. The working area must be sealed with a red and white safety chain and a danger sign.

- Page 17 DC4025 Operating Manual Safety Advices 2.8 For special attention Use only proper and default free tools for your work. Damaged tools have to be repaired immediately or to be replaced. Use during your work for your own safety the requitred safety equipment and safety cloths (e.g.

- Page 18 Operating Manual DC4025 Safety Instructions...

- Page 19 DC4025 Operating Instructions Generals Chapter 3 3.1 Operative Range PAGE: 3.2 Scope of supply PAGE: 3.3 Description of the filter unit PAGE: 3.4 Care and Maintenance PAGE:...

- Page 20 The IMPACTS filter unit DC 4025 is characterised by particularly high economy and simple handling. The IMPACTS filter unit DC 4025 is a compact, efficient filtering unit to operate from middle to larger surface treatment machines. Innovative details grant optimized operation on your building site.

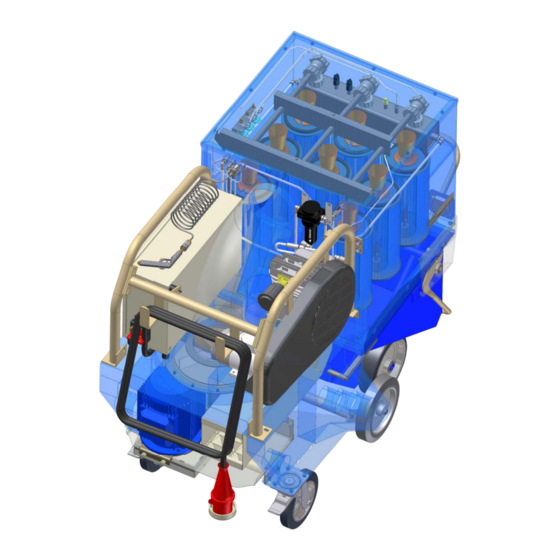

- Page 21 DC4025 Operating Instructions Generals 3.3 Description of the Filter Unit FILTERHOUSING CONTROL PANEL DUSTBIN HOSE CONNECTOR REAR FRAME OPTIONAL MULTI HOSE CONNECTORS BLOWER POWER SUPPLY FOR SUBSYSTEM PULSE CLEANING SYSTEM LIFTING SYSTEM FOR DUSTBIN FILTERHOUSING (1) In the filter housing are the filter cartridges as well as the automatic pulse air system. The filter cartridges separate the dust particles from air and thereby are contaminated, To clean the filter cartridges a pulse cleaning system blows air via valves into them.

- Page 22 Operating Instructions DC4025 Generals DUST BIN (2) and LIFTING (10) Underneath the filter housing is the dust bin, this bin takes up the particles separated by the filter cartridges. The binr seizes approx. 200Ltr and is equipped with two wheels as well as a supporting swivel roller to the light procedure.

- Page 23 DC4025 Operating Instructions Generals Pulse Air Sytem (5) The Pulse Air System is used to clean the filter cartridges while the blower unit is in operation. Conventional Cleaning systems do not allow a cleaning during blower operation. The system essentially consists of three components, the compressor, the pneumatic manifold and the electrical controlling of the pneumatic manifold.

- Page 24 Operating Instructions DC4025 Generals Hose Connectors (7) The Dust Hose (1) will be connected via a Connector (2) being pushed into the side opening and secured by a notched pin (3). Beside the standard hose adapter, optionally multiple connectors are available. Different hose diameters over multiple connectors (4) can be attached.

- Page 25 DC4025 Operating Instructions Generals 3.4 PFLEGE und WARTUNG Careful servicing and regular maintenance of the filter unit is essential for function and safety. Consider unusual noises and examine each change of the operational behaviour of the unit. Call a technician if doubts about the cause exist or a normal remedy without technician doe´s not appear possible.

- Page 26 Operating Instructions DC4025 Generals Notes Date...

-

Page 27: Table Of Contents

DC4025 Operating Manual Transport Chapter 4 4.1 General Notes PAGE: 4.2 Dimensions and Weight PAGE: 4.3 Transport PAGE: 4.4 Transport by Lifting Devices PAGE: 4.5 Transport of the filter by vehicle PAGE: 4.6 Transport during Machine operation PAGE:... -

Page 28: General Notes

We are not liable for damage caused by incorrect use of the filter by personnel not being trained by IMPACTS. 4.2 Dimensions and Weight Model... -

Page 29: Transport By Lifting Devices

DC4025 Operating Manual Transport 4.4 Transport with Lifting Devices When transporting the filter with hoisting equipment like a crane or a lift, check the total weight permitted. (Chapter 1.dimensions) Please use only appropriate, allowed and qualified hoisting equipment as well as roaps and chains . You will find the weight of the equipment in chapter 1 or on the serial plate of the machine. -

Page 30: Transport Of The Filter By Vehicle

Operating Manual DC4025 Transport 4.5 Transport of the filter by vehicle When transporting the machine with vehicles, proceed in such a manner that damage due to the effects of use of force or incorrect loading and unloading is avoided. Use straps and fix them to the intended points (A) to tighten the filter to the cabin of the vehicle. - Page 31 DC4025 Operating Manual Start Up Chapter 5 5.1 Preparing Start Up PAGE: 5.2 Start Up PAGE:...

- Page 32 Operating Manual DC4025 Start Up 5.1 Preparing Start Up Before Start-Up of the filter, operating personnel must have made itself familiar with the safety regulations, which are treated in this manual . Bring the filter on the job side near to the machine to be connected.

- Page 33 DC4025 Operating Manual Start Up 5.2 Start Up After the preparing proceed as follows to Start Up the Equipment. (1) Connect Hose Connector (1) or optional Multiple Connector (2A) with the Dust Hose (2). (2) Push Connector (1) into the port on the filter and lock with the Notched that’s located on...

- Page 34 Operating Manual DC4025 Start Up (8) Switch ON the blower first (7) afterwards switch ON the compressor (6) am by pushing the ON button (7) a. (6). (9) To adjust the airflow to the requirements of the machine that`s connected the filter is equipped with a butterfly valve.

- Page 35 DC4025 Operation Manual Operation Chapter 6 6.1 Operation of the Filter Unit PAGE: 6.2 Dust Bin Dumping PAGE: 6.3 Switch off the filtering unit PAGE: 6.4 Behavior on disturbances PAGE: 6.5 Safety Switch Off PAGE: 6.6 Start Up after Safety Switch Off PAGE: 6.7 Measures before and after lengthy downtimes PAGE:...

-

Page 36: Operation Of The Filter Unit

Operation Manual DC4025 Operation 6.1 Operation of the Filter Unit Start Up and operation of the filtering unit DC4025 do not differ from the proceeding described in chapter 5 “start-up”. Consider however following notes for continuous operation. Daily open the exhaust valve (5) of the compressed air system to discharge condensation. -

Page 37: Dust Bin Dumping

DC4025 Operation Manual Operation 6.2 Dust Bin Dumping The dust bin of the filter unit should be checked regularly for its level. The time intervals depend on the attached machine as well as the surface to be treated. To emptying the Dust Bin place the handle (2) into the desired position. -

Page 38: Switch Off The Filtering Unit

Make sure that all turning parts of the filter unit have stopped e stopped, before any inspection or maintenance work is made. If the IMPACTS filter unit DC4025 is taken for longer time out of operation proceed as follows: Disconnect from Power Supply. -

Page 39: Start Up After Safety Switch Off

DC4025 Operation Manual Operation 6.6 Start Up after Safety Switch Off See Chapter 5.Start Up 6.7 Measures before and after lengthy downtimes Stop of the filter unit over several weeks. Before lengthy downtimes: Clean the filter cartridges again thoroughly starting with a fan completely throttled and the compressor running. - Page 40 Operation Manual DC4025 Operation Notes Date Remarks...

- Page 41 DC4025 Operating Manual Maintenance Chapter 7 7.1 Notice to the DC4025 Dust Collector PAGE: 7.2 Maintenance and Inspection List PAGE: 7.3 Corrective maintenance PAGE: 7.4 Belts PAGE: 7.5 Dismantle and mounting of belts PAGE: 7.6 Belt-tension PAGE: 7.7 Taper-Lock Bushes PAGE: 7.8 Changing Filter-cartridges PAGE:...

-

Page 42: Notice To The Dc4025 Dust Collector

Operating Manual DC4025 Maintenance 7.1 Notice to the DC4025 Dust Collector Prior to any repair work on the machine and its drives, secure the machine against unintentional switch-on. Put the machine to its Safety Off Position as described in chapter 2 Failures due to inadequate or incorrect maintenance may generate very high repair costs and long stoppage periods of the machine. -

Page 43: Maintenance And Inspection List

DC4025 Operating Manual Maintenance 7.2 Maintenance and Inspection List Operating hours/ Inspection points, maintenance instructions time period 12 h after repairing Check function of all safety devices. Check all accessible screw connections for tight seat. Daily and prior Start Check Ground-failure Protection Switches functions Check all Dust Hose Connections to be gastight and secured fitting. -

Page 44: Corrective Maintenance

As already mentioned in Chapter 5 “Initial operation” we recommend to accomplish the first repair works on the machine with the help of IMPACTS personnel.Using this option, your maintenance personnel will have the opportunity to get an intensive training. Only those repair works are described which occur within the context of maintenance or which are required to replace wear parts. -

Page 45: Dismantle And Mounting Of Belts

DC4025 Operating Manual Maintenance 7.5 Dismantle and mounting of belts Remove the belt guard only after the drive motor is at a standstill , the main switch of the filter is OFF and the machine is in Safety Off Position as described in chapter 2. Remove the belt guard. -

Page 46: Taper-Lock Bushes

Operating Manual DC4025 Maintenance 7.7 Taper-Lock Bushes Taper locks are used to shrink-fit hubs on shafts. Mounting and demounting only requires a screw driver DIN 911 (Allan key). Tightening and loosening is effected with the same threaded pins or screws. Taper locks are cylindrical on the inside, tapered on the outside and slit longitudinally. -

Page 47: Changing Filter-Cartridges

DC4025 Operating Manual Maintenance 7.8 Changing Filter-cartridges Before you start changing the cartridges you should clean down as described in Chapter 6.3, afterwards remove the dust-bin. Unpack the new cartridges and place them at side, use the packing for a dust free transport and storing of the older cartridges. -

Page 48: Drive Motors

If the malfunction cannot be repaired, inform please the IMPACTS - customer service. TEL: 0049 2204 4020 0 7.10 Spare Parts Stock To avoid longer down time of the dust collector IMPACTS recommends to stock following parts and quantities. Artikel Nr. Bezeichnung Stk. - Page 49 DC4025 Bedienungsanleitung/Operating Instructions Elektrik / Electrics Chapter 8 8.1 Hint s for the Electrics Page: 8.2 Circuit Diagramm DC4025 (32 Amp) Page: 3-10 Circuit Diagramm DC4025 (63 Amp) Page: 11-18...

- Page 50 VBG 4 or other local regulations. Defects such as loose connections or scorched cables must be rectified immediately. Call a skilled electrician or the IMPACTS customer service. Work on the electrical parts of the equipment have to be undertaken...

- Page 51 DC4025 Bedienungsanleitung/Operating Instructions Elektrik / Electrics 8.2 Electric Wiring 32 Amp...

- Page 52 Betriebsanleitung/Operating Instructions DC4025 Elektrik / Electrics...

- Page 53 DC4025 Bedienungsanleitung/Operating Instructions Elektrik / Electrics...

- Page 54 Betriebsanleitung/Operating Instructions DC4025 Elektrik / Electrics...

- Page 55 DC4025 Bedienungsanleitung/Operating Instructions Elektrik / Electrics...

- Page 56 Betriebsanleitung/Operating Instructions DC4025 Elektrik / Electrics...

- Page 57 DC4025 Bedienungsanleitung/Operating Instructions Elektrik / Electrics...

- Page 58 Betriebsanleitung/Operating Instructions DC4025 Elektrik / Electrics...

- Page 59 DC4025 Bedienungsanleitung/Operating Instructions Elektrik / Electrics 8.3 Electric Wiring 63 Amp...

- Page 60 Betriebsanleitung/Operating Instructions DC4025 Elektrik / Electrics...

- Page 61 DC4025 Bedienungsanleitung/Operating Instructions Elektrik / Electrics...

- Page 62 Betriebsanleitung/Operating Instructions DC4025 Elektrik / Electrics...

- Page 63 DC4025 Bedienungsanleitung/Operating Instructions Elektrik / Electrics...

- Page 64 Betriebsanleitung/Operating Instructions DC4025 Elektrik / Electrics...

- Page 65 DC4025 Bedienungsanleitung/Operating Instructions Elektrik / Electrics...

- Page 66 Betriebsanleitung/Operating Instructions DC4025 Elektrik / Electrics...

- Page 67 DC4025 Operating Manual Diagnosis Chapter 9 9.1 Fault Diagnosis Dust Collector PAGE: 9.2 Fault Diagnosis Electrical System PAGE:...

- Page 68 Operation Manual DC4025 Diagnosis 9.1 Fault Diagnosis Dust Collector Prior to any repair works on the equipment or its drives the equipment must be secured against unintentional switching- on. Put the machine to its Safety off position. Fault Possible cause Failure Corrective Actions Filter gives off dust...

- Page 69 DC4025 Operating Manual Diagnosis 9.2 Fault Diagnosis Electrical System Prior to any maintenance or repair work on the equipment or its drives the equipment must be secured against unintentional switching-on. Put the machine to its Safety off position. Work on electrical equipment or operating materials may only be undertaken by a skilled electrician or by trained persons under the guidance and supervision of a skilled electrician as well as in accordance with the electrical engineering regulations.

- Page 70 Operation Manual DC4025 Diagnosis...

- Page 71 DC4025 Operating Manual Spares Chapter 10 Overview PAGE: Pipe Assembly PAGE: Dust Bin Assy PAGE: Blower Assembly PAGE: Air System PAGE: Notes PAGE:...

- Page 72 Operating Manual DC4025 Spare Parts Overview:...

- Page 73 DC4025 Operating Manual Spares PIPE ASSEMBLY:...

- Page 74 Operating Manual DC4025 Spare Parts DUST BIN ASSY:...

- Page 75 DC4025 Operating Manual Spares BLOWER ASSEMBLY:...

- Page 76 Operating Manual DC4025 Spare Parts AIR SYSTEM: BEZEICHNUNG DESCRIPTION BEST.NR./PT No. FILTERPATRONE C FILTER CARTRIDGE CLASS C 306000002 LUFTVERTEILER ZU DC4025 AIR MANIFOLD DC4025 N300076 DREHSTROMMOTOR COMP. MOTOR 601000020 KOMPRESSOR COMPRESSOR 305000006 RIEMENSCHUTZ DC4025 BELT GUARD COMPLETE N300105 VENTILATOREINHEIT BLOWER UNIT BM N300107 VERSTELLHEBEL ZU DC 4025 ADJ LEVER THROTTLE DC4025...

- Page 77 DC4025 Operating Manual Spares...

- Page 78 Operating Manual DC4025 Spare Parts Notes Date...

Need help?

Do you have a question about the Dustcom 4025 and is the answer not in the manual?

Questions and answers