Table of Contents

Advertisement

P.O. Box 2758

Windsor, Nova Scotia, B0N 2T0

Ph. 902-798-2261

Fax: 902-798-2557

www.nu-airventilation.com

E-mail: nuair@nu-airventilation.com

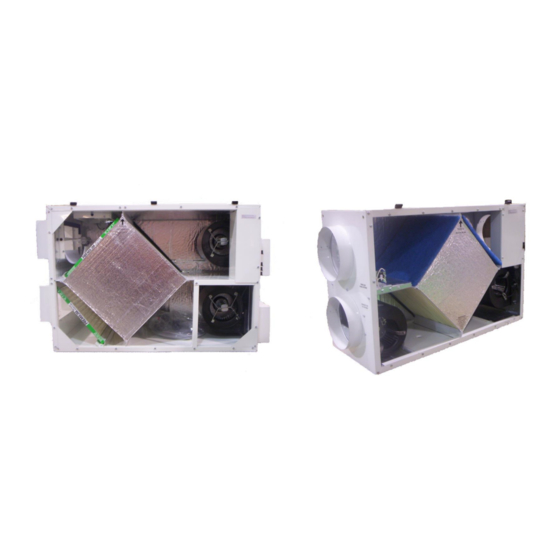

OPERATING, MAINTAINING & INSTALLING YOUR LIGHT COMMERCIAL

HEAT RECOVERY VENTILATOR

IMPORTANT – READ AND SAVE THESE INSTRUCTIONS

* LEAVE THIS DOCUMENT WITH THE BUILDING OWNER

Specifications, dimensions and ratings may change without notice

.

due to ongoing product development and improvements

For products using controller NU-HRV Rev F manufactured April 2013 or later

NU0103, NU0305, NU0406, NU0508, NU0912, NU1316

NU305, NU500, NU600, NU800, NU1200, NU1600

INSTALLATION AND WIRING MUST BE IN ACCORDANCE WITH CEC, NEC AND

LOCAL ELECTRICAL CODES.

Advertisement

Table of Contents

Summary of Contents for Nu-Air NU0103

- Page 1 For products using controller NU-HRV Rev F manufactured April 2013 or later NU0103, NU0305, NU0406, NU0508, NU0912, NU1316 NU305, NU500, NU600, NU800, NU1200, NU1600 INSTALLATION AND WIRING MUST BE IN ACCORDANCE WITH CEC, NEC AND...

- Page 2 NEVER attempt to repair or service any internal component of this H/ERV while the unit is plugged in or running. DO NOT use your ventilation system to exhaust flammable fumes or gasses. ALWAYS contact your Nu-Air representative if you have any questions or comments about the operation or maintenance of your Nu-Air H/ERV—we are here to help you! ALWAYS contact your Nu-Air representative if you have any questions or comments about the operation or maintenance of your Nu-Air H/ERV—we are here to help you!

-

Page 3: Table Of Contents

Selectable Furnace/Air Handler Interlock ................... 16 Furnace/Air Handler Interlock Wiring ..................17 Defrost Operation ..........................18 Balancing the System ........................19 10.1 Balancing Procedure: NU0103/NU305, NU0305/NU500, NU0406/NU600 ........ 20 10.2 Balancing Procedure: NU0508/NU800, NU0912/NU1200, NU1316/NU1600 ......21 Maintenance ............................ 21 Troubleshooting ..........................23 Electrical Schematics ........................ -

Page 4: How The Nu-Air System Works

Intelligent defrost. Self-resetting fuse to protect the board against mis-wiring. Motor speed control (NU0103, NU0305, NU0406 only) – Motors can be independently adjusted in HRV high and low speeds. Optional setting for 220V/50Hz geographic areas. Fan interlock 3 Installation Instructions Installer’s Responsibilities... -

Page 5: Ductwork

1. Standard Issue Items The HRV comes equipped with: Filters Heat/Energy Recovery Core Drain Kit Anti-Vibration straps (NU0103, NU0305) Anti-vibration Springs, chain & hanging brackets (NU0406) 2. Other Basic Needs Control Package Galvanized Duct Flexible Duct Connector Outside Hoods (2) -

Page 6: Weather Hoods

Weather Hoods Locating the Weather Hoods (Commercial Installations) Designers should try to locate the hoods in such a way that there is easy access for cleaning purposes. The H/ERV should be located close to the outside wall(s) containing the hoods, the resulting short duct lines will minimize airflow losses. -

Page 7: Port Configurations

3 - FROM SPACE 4 - TO OUTSIDE 1 & 4 Insulated 2 & 3 Non-Insulated C or G for NU0103, NU0305, NU0608, NU0912, NU1316 (NU305, NU500, NU800, NU1200, NU1600) A or E for NU0406 (NU600) Collar Sizes (inches) NU0103/NU305... -

Page 8: Mounting And Noise Control

Avoid hanging the HRV directly below a bedroom or other quiet area. Nu-Air EZ System Features: EZ Level, EZ Balance Included in orders shipped after November 1, 2016... - Page 9 NU0406 – NU1316 & NU600-NU1600: The H/ERV is designed to be hung from the ceiling by way of the anti-vibration springs and chain supplied. You will also need bolt cutters or snips and self-tapping screws. The following items are included with the H/ERV: ...

-

Page 10: Drain Connections

For electrical hook-up, the H/ERV should be connected to its own circuit using electrical wire and conduit in accordance with code requirements. Nu-Air H/ERVs are equipped for remote controls. Options include occupancy, humidity and gas sensors, timers, off/on/intermittent-on, and low-high switching. -

Page 11: Unit Controls: Operation And Wiring

6 Unit Controls: Operation and Wiring Your unit is equipped with 12 VDC and 24 VAC removable terminal blocks. The control logic of the unit circuit board is such that the most recently used remote control will control the unit. If desired, 12 VDC and 24 VAC controls may be used in the same installation. - Page 12 Rec.: Unit operates in full-time recirculation with no outdoor air exchange.4 Low and circulation cycles are overridden by a high speed signal from another control. M4 can only be used with HRV equipped with recirculation capability: NU0103, NU0305, NU0406, NU0508, NU0912, NU1316 with circulation defrost.

-

Page 13: Control Wiring - Applicable To All Es Series Controls

See “Lumina Wall Control and Installation Guide” for details. ES Control Wiring – applicable to all ES series controls 6.1.1 Crossing the +12V/12 and ground (G) wires might short-circuit and destroy the ES wall control processor. Note: If you are using ONLY an ES-T1 to control your unit, you must connect a jumper wire between R and SB on the 24V (10-wire) removable terminal block. -

Page 14: Standard Dehumidistat (Part # Dstat-1) & 2-Wire Switches

Where required, C terminal may be used for controls requiring external 24 VAC power source. PURPLE For two-wire switching, and where local building regulations permit, PURPLE Nu-Air recommends a jumper wire between R and SB to engage the unit in standby mode. DSTAT-1 6.2.4 Windsor Control (Part # WIN-1) - Page 15 Win-20 Timer Up to 6 Win-20 timers may run off of one system. PWR (red) If using only the Win-20 timer as a means of remote LED (yellow) control, connect jumper wire between R and SB. SWITCH (black) WIN-20 Rev 2.3 July 17, 2017...

-

Page 16: Control Board Status Leds

7 Control Board Status LEDs The control board is equipped with LEDs which indicate the unit’s current state of operation. CONDITION LED AND STATUS NO LED UNIT/TRANSFORMER IS NOT POWERED UNIT OFF Red is off, Green is blinking slow, every 1 s. Also indicates processor is programmed and running. -

Page 17: Furnace/Air Handler Interlock Wiring

Furnace/Air Handler Interlock Wiring THERMOSTAT TERMINALS THERMOSTAT TERMINALS COOLING SYSTEM COOLING SYSTEM ALTERNATE FURNACE INTERLOCK STANDARD FURNACE INTERLOCK If the standard interlocking method has the unwanted effect of bringing on the AC, i.e. thermostats that do not isolate “G” from “Y”, use the alternate method shown above. -

Page 18: Defrost Operation

9 Defrost Operation Proportional Defrost Cycles Your unit will adjust defrost frequency and duration, based on outdoor temperature: -5º C (23º F) -15º C (5º F), -20º C (-4º F) and -27º C (-17º F). Circulation Defrost: When outdoor temperature is below -5º C (23º F), a defrost cycle is initiated for a fixed duration. The fresh air motor will run and the exhaust air motor will shut down. -

Page 19: Balancing The System

10 Balancing the System Once the H/ERV system is installed, do the following: 1. Close all windows and doors. 2. Turn off any exhaust only systems. 3. To balance the H/ERV, set the machine on high speed. 4. Make a small hole in the supply duct at least 2 feet down stream of the motor. Insert a Pitot tube in the cross sectional center of the duct. -

Page 20: Balancing Procedure: Nu0103/Nu305, Nu0305/Nu500, Nu0406/Nu600

6. To convert pressure readings to airflow (cfm or L/s) refer to the instructions and table included with the air meter. 10.1 Balancing Procedure: NU0103/NU305, NU0305/NU500, NU0406/NU600 Balanced air flow between the supply and exhaust air streams is essential to the performance of an HRV or ERV. -

Page 21: Balancing Procedure: Nu0508/Nu800, Nu0912/Nu1200, Nu1316/Nu1600

Low-Speed Adjustment/Balancing. If low speed adjustment is desired, follow the same process to adjust high speed, but use a jumper wire or remote control to put the unit into low speed to make low speed adjustments 10.2 Balancing Procedure: NU0508/NU800, NU0912/NU1200, NU1316/NU1600 For units with the larger, fractional horsepower motors, electronic speed adjustment using the method described above has been disabled. - Page 22 Diffusers and Ductwork Clean the diffusers with soap and water when they are dusty or otherwise noticeably dirty. Exhaust diffusers require more frequent cleaning than supply diffusers. ANNUAL SERVICING Your H/ERV should undergo annual general servicing by an accredited contractor. This servicing should include the following: The six maintenance items above.

-

Page 23: Troubleshooting

12 Troubleshooting SYMPTOM EXPLANATION ANSWER Frosting up of HRV and/or HRV air flows incorrectly balanced. Balance HRV. Duct(s). HRV defrost system is not working. Install dampers. Check defrost system. Note minimal frost build up is expected on cores before unit initiates defrost cycle function. -

Page 24: Electrical Schematics

13 Electrical Schematics There are a number of configurations and options available for these products. The schematic specific to your unit was supplied with the equipment. The following pages illustrate typical, generic, schematics. Your equipment may vary. Rev 2.3 July 17, 2017... - Page 25 Rev 2.3 July 17, 2017...

- Page 26 Rev 2.3 July 17, 2017...

- Page 27 Rev 2.3 July 17, 2017...

- Page 28 Rev 2.3 July 17, 2017...

- Page 29 Rev 2.3 July 17, 2017...

- Page 30 Rev 2.3 July 17, 2017...

- Page 31 Rev 2.3 July 17, 2017...

- Page 32 Rev 2.3 July 17, 2017...

- Page 33 Rev 2.3 July 17, 2017...

- Page 34 Rev 2.3 July 17, 2017...

- Page 35 Rev 2.3 July 17, 2017...

- Page 36 Rev 2.3 July 17, 2017...

- Page 37 Rev 2.3 July 17, 2017...

- Page 38 Rev 2.3 July 17, 2017...

-

Page 39: Warranty

Core Warranties If the polypropylene core in your NU-AIR Heat Recovery Ventilator (HRV) fails due to a defect in material or workmanship within fifteen (15) years NU-AIR Ventilation Systems Inc. will supply a new core FOB Factory to replace the defective part. Delivery and labour costs are customers responsibility. - Page 40 Windsor, Nova Scotia 16 Nelson St. P.O Box 2758 B0N 2T0 Canada Ph: 902-798-2261 Fax: 902-798-2557 Email: nuair@nu-airventilation.com Web: www.nu-airventilation.com Email: nuair@nu-airventilation.com Website: www.nu-airventilation.com Rev 2.3 July 17, 2017...

Need help?

Do you have a question about the NU0103 and is the answer not in the manual?

Questions and answers