Table of Contents

Advertisement

Fisher Engineering

50 Gordon Drive, Rockland, Maine 04841-2139 • www.fi sherplows.com

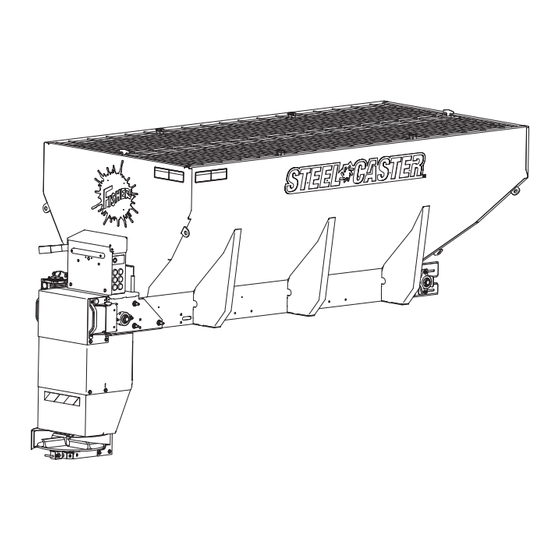

STEEL-CASTER™ Hopper Spreader

This manual is for FISHER

with serial numbers beginning with 170711 and higher.

This document supersedes all editions with an earlier date.

with Electric Motors

Installation Instructions

CAUTION

Read this document before installing or

operating the spreader.

STEEL-CASTER Hopper Spreaders

®

99000-1, 99001-1

99005-1, 99009-1

August 1, 2018

Lit. No. 43765, Rev. 02

Advertisement

Table of Contents

Summary of Contents for Fisher Engineering STEEL-CASTER Series

- Page 1 99000-1, 99001-1 Fisher Engineering 99005-1, 99009-1 50 Gordon Drive, Rockland, Maine 04841-2139 • www.fi sherplows.com August 1, 2018 Lit. No. 43765, Rev. 02 STEEL-CASTER™ Hopper Spreader with Electric Motors Installation Instructions CAUTION Read this document before installing or operating the spreader.

-

Page 3: Safety Definitions

SAFETY SAFETY DEFINITIONS WARNING/CAUTION LABELS Become familiar with and inform users about the WARNING warning and caution labels on the spreader. Indicates a potentially hazardous situation that, if not avoided, could result in death or NOTE: If labels are missing or cannot be read, see serious personal injury. -

Page 4: Safety Precautions

SAFETY SAFETY PRECAUTIONS CAUTION • Do not operate a spreader in need of Improper installation and operation could cause maintenance. personal injury and/or equipment and property damage. • Before operating the spreader, reassemble Read and understand labels and the owner's manual any parts or hardware removed for cleaning before installing, operating, or making adjustments. - Page 5 SAFETY FIRE AND EXPLOSION NOISE Airborne noise emission during use is below 70 dB(A) WARNING for the spreader operator. Gasoline is highly fl ammable and gasoline vapor is explosive. Never smoke while VIBRATION working on vehicle. Keep all open fl ames away from gasoline tank and lines.

-

Page 6: Load Volume

LOADING LOAD VOLUME This document covers vehicles that have been recommended for carrying the hopper spreader. Please see your local dealer for proper vehicle applications. Load Volume ( Hopper Model WARNING 7 ft (1.7 yd Overloading could result in an accident or 8 ft (2.0 yd damage. -

Page 7: Mounting The Spreader

MOUNTING THE SPREADER INSTALL TOP SCREEN BRACKETS NOTE: Periodically throughout the snow and ice control season, verify that mounting devices 1. Install a top screen bracket at each end of are secure. the spreader cross beams using the supplied 1/4" x 3/4" carriage bolts, 1/4" washers, and INSTALL INVERTED V 1/4"... - Page 8 MOUNTING THE SPREADER INSTALL HOPPER IN TRUCK BED CAUTION Before drilling holes, check to be sure that no 1. Remove the vehicle tailgate. vehicle wiring or other components could be damaged. 2. Remove the wood shipping rails from the hopper legs.

- Page 9 MOUNTING THE SPREADER INSTALL CHUTE 8. Install the top screens, using the retained linch pins to secure the screens to the previously installed brackets. The chute comes in two lengths. • 7' and 8' Hoppers: Short chute confi guration is Construct Sill Spacer standard.

- Page 10 MOUNTING THE SPREADER Install Chute to Spreader INSTALL TIE-DOWN STRAPS Before installing the chute to the hopper, confi rm that Install tie-down straps from the tie-down loops on the the spinner turns freely. If it does not, refer to "Spinner spreader body to the truck frame.

-

Page 11: Wiring Instructions

WIRING AND HARNESS INSTRUCTIONS WIRING INSTRUCTIONS Vehicle Battery Cable Installation Spreaders are shipped from the factory with the 1. Remove the battery cables from the vehicle spreader harness wired to the motor and spreader battery. module. 2. Using the 1/4" x 3/4" cap screws, 1/4" fl at washers, To properly wire the hopper spreader, follow this and /1/4"... - Page 12 WIRING AND HARNESS INSTRUCTIONS Vehicle Control Harness Installation 5. Insert a rubber grommet into the hole. 6. Route the harness as laid out in Step 2. 1. Plug the vehicle harness into the spreader harness. Secure the vehicle control harness to the truck. 2.

- Page 13 WIRING AND HARNESS INSTRUCTIONS CENTER HIGH-MOUNTED STOPLIGHT 4. Install the control side of the bracket to the vehicle side using 1/4" x 1/2" Phillips head machine (CHMSL) screws, 1/4" nylon shoulder washers, 1/4" lock washers, and 1/4" hex nuts. An LED center high-mounted stoplight is standard equipment on all stainless steel hopper spreaders.

-

Page 14: Electrical Components

ELECTRICAL COMPONENTS VEHICLE HARNESS DIAGRAM Cab Control 18 ga Red 4-Way Connector To Vehicle Switched Accessory To Vehicle CHMSL Signal (tap located in cab) Connectors 18 ga Shielded Twisted-Pair Cable 6 ga Red 100A Fuse 4 ga Red 18 ga Black 4 ga Black To Vehicle CHMSL Signal (tap located in rear of vehicle) -

Page 15: Final Adjustments

FINAL ADJUSTMENTS CONVEYOR PINTLE CHAIN TENSION SPINNER BELT ALIGNMENT To check the conveyor chain tension, see whether the If the spinner does not turn freely, check the spinner chain is visible in the chain tension port. If the chain is belt alignment. - Page 16 Fisher Engineering reserves the right under its product improvement policy to change construction or design details and furnish equipment when so altered without reference to illustrations or specifi cations used. Fisher Engineering or the vehicle manufacturer may require or recommend optional equipment for spreaders. Do not exceed vehicle ratings with a spreader. Fisher Engineering offers a limited warranty for all spreaders and accessories.

Need help?

Do you have a question about the STEEL-CASTER Series and is the answer not in the manual?

Questions and answers