Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Atosa ATO-4B-F

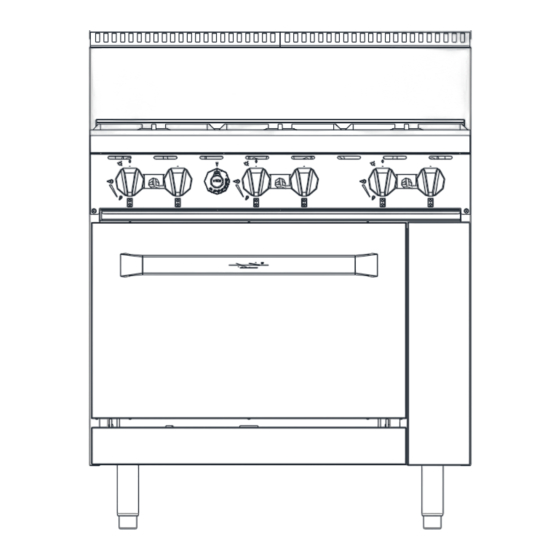

- Page 1 Gas Restaurant Ranges Operating Instructions (Flame out protection) Before you begin, please read these instructions carefully to use this product correctly, to make the product perform ideally, and to avoid hazards. Models: ATO-4B-F/ ATO-6B-F / ATO-8B-F...

- Page 2 Dear customers and users: Thank you for purchasing our products. In order to be able to better use this product, please read these instructions carefully before any operation, and follow the guide, to avoid any unnecessary trouble during using. Please keep this instruction manual in a safe place for convenient reference and operation.

-

Page 3: Table Of Contents

Gas Restaurant Ranges The Installation, Operation and Maintenance Guide Contents 1. Safety Protection ……………………………………………………3 2. Brief Introduction……………………………………………………3 3. Manufacturer's Authority and Responsibility……………………3 4. Parameter Specifications……………………………………………4 5. Transport and Storage…………………………………………………8 6. Installation and Debugging …………………………………………8 7. Safety Notices and Precautions……………………………………11 8. Operating Instructions…………………………………………… 12 9. -

Page 4: Safety Protection

1、Safety Protection Please make sure that the operator is an authorized and licensed technician before you allow him/her to install and operate the products. Be sure to strictly follow this instruction guide during installation and using. The manufacturer is not responsible for any dangers or accidents caused by improper operation or maintenance. -

Page 5: Manufacturer's Authority And Responsibility

Be repaired or changed by unauthorized technicians; Use the spare parts or accessories provided by non-manufacturers; Accidents caused by force majeure; Not strictly comply with related guide of this instruction by any reason. 4、Parameter Specifications 4.1、Outline Dimensions(mm) ATO-4B-F - 4 -... - Page 6 ATO-6B-F - 5 -...

- Page 7 - 6 -...

- Page 8 ATO-8B-F 4.2:Size and package parameter information - 7 -...

- Page 9 Packing size Model dimensions dimensions er of L x W x H L x W x H L x W x H oven 610*790*116 508*660*35 ATO-4B-F 675*990*1050 914*790*116 673*660*35 ATO-6B-F 980*990*1050 508*660*35 ATO-8B-F 1219*790*1165 1285*990*1050 4.3:Information of Gas Supply and Burner The minimum supplied gas pressure regulator is factory set at 1.13kPa for...

- Page 10 L.P. Gas ULPG Natural ATO-6B- L.P. Gas ULPG Natural ATO-8B- L.P. Gas ULPG Gas Connection: NOTE: ALL GAS FITTING MUST ONLY BE CARRIED OUT BY AN AUTHORISED PERSON. The appliances do not require an electrical connection, as they function totally on the gas supply only. It is essential that th ly is correct for the appliance to be e gas supp...

-

Page 11: Transport And Storage

Particular note should be taken if the appliance is being added to an existing installation NOTE : It is important that adequately sized piping runs directly to the connection joint on the appliance with as few tees and elbows as possible to give maximum supply volume. - Page 12 Please dispose of all packaging materials and residues after unpacking; Check the equipment. If it is damaged, please keep wrappers and receipts which must be signed by the carrier representative (Driver), and contact the carriers to pursue a claim within 15 days after receiving; Be sure to install supporting legs before using, and do not tear up any label or logo before normal using;...

- Page 13 bottom, in order to avoid influencing combustion and air circulation; Leave enough distance in front of the equipment to take apart the control panel. All major parts, in addition to the burner remove from the front intake-tube; It may be necessary to adjust the balance of air input by authorized and licensed technicians;...

-

Page 14: Safety Notices And Precautions

6.2 Debugging It’s very important to debug the new stove. Through the comprehensive system test of equipment, we can ensure function and safety performance of products. Discovering any potential problems before use (such as equipment’s placement, ventilation, operation, etc), can avoid costly losses. - Page 15 Warning! Any erroneous installation, adjustment and refit may cause property damage or personal injury and maintenance failure. Read the instructions carefully before installation and using. Warning! Operation instruction must be placed in a conspicuous location. When customers smell gas in the process of using, should take safety precautions immediately.

-

Page 16: Operating Instructions

otherwise, may cause hazards, and the manufacturer has the right not to provide warranty service; Steel cutting producers used to manufacture with sharp edges. The manufacturer has dealt with these sharp edges during production, however, we insist the operator take care when in contact with this piece of equipment;... - Page 17 the pipe. Wait a minute, the pilot light will be lighted after the gas extinguished. 8.2 Igniting the main burner(hot plates) evolve the main fire control valve knob anticlockwise after lighting the pilot light, and then the main fire burner is ignited by the pilot light. When knob reaches to "...

- Page 18 repeat this action until the fire is ignited, and observe stability of fire. Figure 7 Figure 8 Figure 9 Tip :The pilot light may not be lighted immediately, for existing gas in the pipe. Wait a minute, the pilot light will be lighted after the gas extinguished. 8.4 Igniting the main burner(oven)...

- Page 19 ②Axial press the knob to rotate knob clockwise continually, so that the direction of the knob on the "O" position, at this time, the fire extinguished, the valve closed. 2、Oven Revolve the control valve knob clockwise to "0" (Fig.6), so that extinguish flame of the main burner, but the pilot light still works.

- Page 20 the appliance does not get loose. At last, reinstall the underside face plate of oven. Caution: Each burner damper has been adjusted before delivery (once air input), Normal use without adjustment but only switching gas. Adjust only by authorized and licensed technicians. 8.8 Exchange the pilot assemblies and the nozzle to switch gas source ①...

-

Page 21: Cleaning And Maintenance

Caution: Each main fire nozzle of the burner has been installed before delivery, normal use without adjustment but only switching gas. Adjust only by authorized and licensed technicians. When you change the gas source, you need exchange the corresponding pressure maintaining valve which installed on air intake. - Page 22 Table3 Items Methods Times Wipe it with a soft cloth and mild Body daily detergent; Turn off valves when not in use; Control panel Wipe panel and control valve knob with daily mild detergent. Pull out catch tray from front body until the equipment cools down.

-

Page 23: Troubleshooting

coating of oven inner wall. 10. Troubleshooting Table 4 Problem Possible causes Problems solving 1.Insufficient 1.Contact the local Not lighting pressure in pipe gas supply dept. 2.Nozzle occlusion 2.Dredge nozzle 1.Insufficient 1.Contact the local pressure in pipe gas supply dept. Ignite pilot 2.The main fire nozzle... - Page 24 main fire’s distance is too distance of them 5.Adjust the height 5.Flame is too low of the pilot light 1.Insufficient 1.Contact the local pressure in pipe gas supply dept. 2.Not match nozzle 2.Adjust nozzle Close aperture with diameter resources heard a sound of fire 3.Flow of connection 3.Increase...

-

Page 25: Schematic Diagram For Installation Of Chimney

The problems mentioned above are only for reference. If any fault occurs, please stop using, and contact technicians to check and repair. Safety first, turn off the power and gas supply before maintenance. Schematic diagram installation of the chimney - 24 -... - Page 26 Step I Step II (Remove the self-tapping (Fix the inserted bar with the screws shown in the figure chimney by the self-tapping below,Insert the inserted screws that were just removed) bar into the corresponding position of the chimney) Step III Step IV ( Insert the assembled (Fix the assembled...

- Page 27 2、When the regulator is connected, the maximum load value of natural gas can not exceed 1.13kPa, the maximum value of liquefied gas can not exceed 2.75kPa. 3、Screw the hex nut (Fig.17) before connect air intake, ensure gas mark (Fig.18) on the plastic core match with connected gas source, if not, then pull out the plastic core and change another head, insert it again.

- Page 28 - 27 -...

Need help?

Do you have a question about the ATO-4B-F and is the answer not in the manual?

Questions and answers