Summary of Contents for MTI DUCAR DLG4000iSE

- Page 1 USER MANUAL Distribué par / Distributed by : MTI Canada Tél. / tel.: 418 839-4127 Français: 1 800 463-4398 English: 1 800 463-7205 Téléc. / Fax: 1 800 363-7157 www.mticanada.ca • info@mticanada.ca...

- Page 2 DISCLAIMERS: DANGER ......................................................22 WARRANTY...

-

Page 3: Safety Symbol Definitions

SAFETY SAFETY DEFINITIONS SAFETY SYMBOL DEFINITIONS The words DANGER, WARNING, CAUTION and NOTICE are used throughout this manual to highlight important information. Be certain that the meanings of these alerts are known to all who work on or near the equipment. -

Page 4: General Safety Rules

SAFETY GENERAL SAFETY RULES DANGER Never use the inverter in a location that is wet or damp. Never expose the inverter to rain, snow, water spray or standing water while in use. Protect the inverter from all hazardous weather conditions. Moisture or ice can cause a short circuit or other malfunction in the electrical circuit. Never operate the inverter in an enclosed area. -

Page 5: Fuel Safety

SAFETY FUEL SAFETY When transporting or servicing the generator: DANGER • Make certain the fuel shutoff valve is off and the fuel tank is empty. Gasoline and liquid petroleum gas • Make sure the LPG tank and LPG hose is not attached (LPG) are highly explosive and to the generator. -

Page 6: Basic Inverter Features

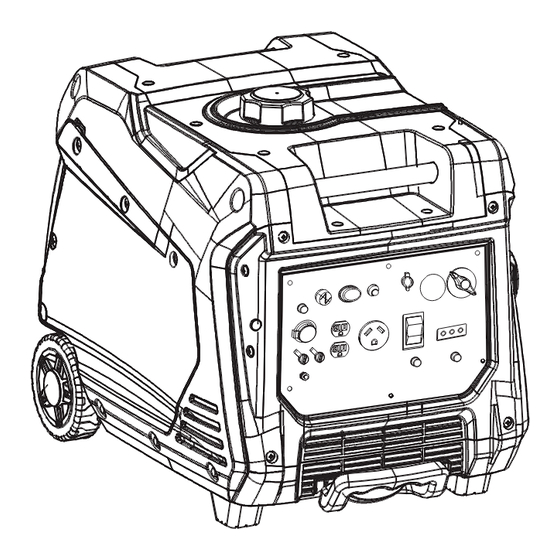

FEATURES BASIC INVERTER FEATURES Control Panel: Contains the reset breaker, Roller Board Wheels: For easy portability. outlets and warning lights. Telescoping Handle: Extends and retracts for Oil Access Cover: Remove the cover to easy access. access the oil fill/drain plug. Carry Handles: Built in handles to allow for Recoil Handle: Pull to manually start the easy pick up. -

Page 7: Operation

OPERATION BEFORE STARTING THE INVERTER CONTROL PANEL FEATURES BEFORE STARTING THE INVERTER, REVIEW SAFETY SECTION STARTING Receptacles ON PAGE 3. These can be used for operating appropriate appliance, electrical lighting, tools, and motor Location Selection – Before starting the inverter, avoid loads. - Page 8 OPERATION Weather – Never operate your inverter outdoors during WARNING rain, snow or any combination of weather conditions that could lead to moisture collecting on, in or around the Be sure the inverter is properly generator. connected to earth ground before operating.

-

Page 9: Power Cord

OPERATION POWERCORD Using Extension Cords Westinghouse Portable Power assumes no responsibility for the content within this table. The use of this table is the responsibility of the user only. This table is intended for reference only. The results produced by using this table are not guaranteed to be correct or applicable in all situations as the type and construction of cords are highly variable. -

Page 10: Initial Oil Fill

OPERATION INITIAL OIL FILL ADDING/CHECKING ENGINE FLUIDS AND FUEL BEFORE ADDING ENGINE OIL, REVIEW BEFORE ADDING/CHECKING ENGINE SAFETY SECTION STARTING ON PAGE . FLUIDS AND FUEL, REVIEW SAFETY SECTION STARTING ON PAGE . NOTICE DANGER Engine oil must be added when the inverter is on a Filling the fuel tank with gasoline while flat, level surface, or an inaccurate reading may result. -

Page 11: Adding Gasoline To The Fuel Tank

OPERATION CONNECTING THE LPG/PROPANE TANK ADDING GASOLINE TO THE FUEL TANK BEFORE CONNECTING PROPANE TANK WARNING TO THE GENERATOR PLEASE REVIEW FUEL SAFETY SECTION ON PAGE Never refuel the inverter while the Connecting LPG Tank engine is running. 1. Make sure the inverter is off, on a flat surface in well ventilated area. -

Page 12: Starting The Inverter

OPERATION STARTING THE INVERTER 5. Select fuel source for start up: FOR GASOLINE BEFORE STARTING THE INVERTER, a. Make sure there is gas in the tank (see Adding REVIEW SAFETY SECTION Gasoline to the Fuel Tank). STARTING ON PAGE . b. -

Page 13: Using Efficiency Mode

OPERATION SWITCHING FUEL SOURCES USING EFFICIENCY MODE The inverter is equipped with an efficiency mode switch to minimize fuel consumption. In efficiency mode, the PLEASE REVIEW FUEL SAFETY inverter will sense the load and adjust the engine RPM SECTION ON PAGE to the current load requirements. -

Page 14: Maintenance

MAINTENANCE BEFORE PERFORMING MAINTENANCE ON THE INVERTER, REVIEW THE SAFETY SECTION STARTING ON PAGE , AS WELL AS THE FOLLOWING SAFETY MESSAGES. WARNING CAUTION Avoid accidentally starting the inverter Avoid skin contact with engine oil or during maintenance by removing gasoline. - Page 15 MAINTENANCE ENGINE OIL MAINTENANCE NOTICE Engine Oil Specification Engine oil must always be checked and added when 1. Only use the engine oil specified in Figure 1 . the inverter is on a flat, level surface, or an inaccurate reading may result, causing serious engine damage. 2.

-

Page 16: Air Filter Maintenance

MAINTENANCE AIR FILTER MAINTENANCE 4. Remove the foam element from the air cleaner housing. WARNING 5. Wash the foam air filter element by submerging Never use gasoline or other flammable the element in a solution of household detergent solvents to clean the air filter. Use only soap and warm water. -

Page 17: Draining The Float Bowl

MAINTENANCE DRAINING THE FLOAT BOWL SPARK PLUG MAINTENANCE The spark plug must be checked and cleaned after ev- 1. Remove the Engine Service Panel to access the ery 100 hours of use or 6 months and must be replaced carburetor (see Figure 11 on page 1 ). after 300 hours of use or every year. -

Page 18: Cleaning The Spark Arrestor

MAINTENANCE Spark Plug Maintenance - Continued from page 18 7. Place a clean rag over the opening created by the removal of the spark plug to make sure no dirt can get into the combustion chamber. 8. Inspect the spark plug for: SPARK PLUG GAP •... -

Page 19: Battery Service

MAINTENANCE BATTERY SERVICE 4. Both the rocker arms should be loose at TDC on the compression stroke. If they are not, rotate the To ensure the battery remains charged, the generator engine 360°. should be started every 2 to 3 months and run for a minimum of 15 minutes or a charger should be plugged . - Page 20 MAINTENANCE STORAGE 5. Change the oil (see Changing Engine Oil on page 16). WARNING 6. Remove the spark plug (see Spark Plug Never store an inverter with fuel in the Maintenance on page 18) and place about 1 tank indoors or in a poorly ventilated tablespoon of oil in the spark plug opening.

-

Page 21: Troubleshooting

TROUBLESHOOTING WARNING Before attempting to service or troubleshoot the generator, the owner or service technician must first read the owner’s manual and understand and follow all safety instructions. Failure to follow all instructions may result in conditions that can lead to voiding of the product warranty, serious personal injury, property damage or even death. PROBLEM POTENTIAL CAUSE SOLUTION... -

Page 22: Warranty

TROUBLESHOOTING 1. Propane fuel line kinked or crushed. other obstructions. Poor performance or engine stalling on 3. Gasoline not purged from the carburetor before switching to propane. propane allow the engine to run until the fuel has been consumed in the carburetor. Begin propane start up procedure.

Need help?

Do you have a question about the DUCAR DLG4000iSE and is the answer not in the manual?

Questions and answers