Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Jacuzzi J-HN250C

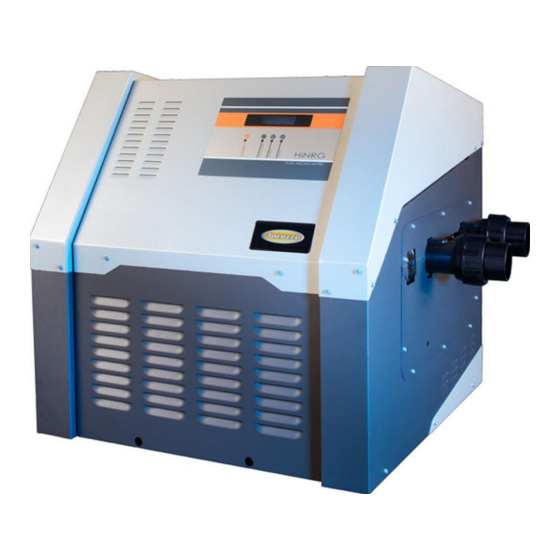

- Page 1 Jacuzzi ® J-HN250C, J-HN400C Heater Installation and Operating Instructions...

- Page 2 IMPROPER INSTALLATION, ADJUSTMENT, MODIFICATION, SERVICE OR MAINTENANCE CAN CAUSE IMPROPER OPERATION RESULTING IN PROPERTY DAMAGE, PERSONAL INJURIES, OR DEATH. INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER, SERVICE AGENCY, OR JACUZZI® WHAT TO DO IF YOU SMELL GAS YOUR DO NOT TRY TO LIGHT ANY APPLIANCE.

- Page 3 CARBON MONOXIDE GAS IS DEADLY : Exhaust gases from this pool heater may contain toxic levels of Carbon Monoxide , a dangerous and poisonous gas that you cannot see or smell SAVE THESE INSTRUCTIONS - 2 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

- Page 4 Some jursdictions may require that installers be Licensed. Check with your local building code authority about contractor licensing requirements. Improper installation and/or operation could create carbon monoxide in flue gases which could cause serious injuries, or death. Improper installation and/or operation will void the warranty. - 3 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

- Page 5 (communicating) to occupied areas, See Venting Section of this manual for more details. - 4 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

- Page 6 IT IS STRONGLY RECOMMENDED THAT BATTERT OPERATED, LISITED CARBON MONOXIDE DETECTORS(ALARMS) BE INSTALLED IN ANY OCCUPIED SPACES ADJACENT TO INSTALLED HEATER, AND FOR INDOOR HEATER INSTALLATIONS INSTALL AN ADDITIONAL CARBON MONOXIDE DETECTOR(ALARM) NEAR THE LOCATION OF THE HEATER - 5 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

-

Page 7: Table Of Contents

NORMAL HEATER OPERATION …………………………………………………………………………………………………27 HEADER CONVERSION FROM RIGHT TO LEFT INLET / OUTLET …………………………………………………………..28 TESTING GAS PRESSURE …………………………………………………………………………………………………………31 PERFORMANCE DETAILS …………………………………………………………………………………………………………32 TROUBLE SHOOTING …………………………………………………………………………………………………………….33 ELECTRICAL DIAGRAM …………………………………………………………………………………………………………...33 MAINTENANCE OF YOUR POOL HEATER ……………………………………………………………………………………..34 - 6 - INST 396 Jacuzzi® J-HN Series Heater V12-16... -

Page 8: Introduction

The Jacuzzi® J-HN Series heater can safely be connected to PVC pipe. It accepts a wide range of water flow rates from as little as 31gallons (120 liters) per minute making it perfectly suitable for energy efficient variable speed pool and spa pumps. In addition, it is equipped with electronic start up and an accurate electronic thermostat to ensure ease of use and accurate temperature control. -

Page 9: Operating Instructions

TO TURN OFF GAS TO HEATER TURN OFF ALL ELECTRIC POWER TO THE HEATER IF SERVICE IS TO BE PERFORMED. Turn off manual Gas tap in gas supply line prior to Heater - 8 - INST 396 Jacuzzi® J-HN Series Heater V12-16... -

Page 10: Chemical Balance

Pool’s intention is to provide a little understanding of the potential problems of water chemistry and the dangers of corrosion to heaters (and other pool equipment and fittings). YOUR WATER SHOULD BE ADJUSTED & BALANCED PRIOR TO ANY CORRODED PARTS BEING REPLACED. - 9 - INST 396 Jacuzzi® J-HN Series Heater V12-16... -

Page 11: Digital Thermostat Operation

F0 to F3. To reset a lock out condition, turn the power off for five seconds. When the water temperature is heated to within 1.8°F of the thermostat set point, the Jacuzzi® J-HN Series series heater burner will turn down so that the set point is not exceeded. In addition, the set point is maintained very accurately, so that when using your spa or pool, you will notice very little variation in water temperature. -

Page 12: Display Symbol Indication

If the heater is below water level, isolate it from the pool first by closing shut off valves before and after the heater. CAUTION: If the heater has been drained for freezing conditions, do not turn on until the system is circulating water - 11 - INST 396 Jacuzzi® J-HN Series Heater V12-16... -

Page 13: Installation

So minimise their use. Step the piping size down as close to the heater as possible. The Jacuzzi® J-HN series heater requires a minimum supply pressure of 5 in w.c. for natural gas and 11 in w.c. for propane (LPG). -

Page 14: Heater Dimensions

Plumbing in high pressure 2” (50mm)PVC pipe. Connections to heater in Class 12 or higher. All Salt System Chlorinators or Sanitisers to MUST be installed after the heater. HEATER DIMENSIONS - 13 - INST 396 Jacuzzi® J-HN Series Heater V12-16... -

Page 15: Indoor Flue Installion

Do not over bend and kink flue pipe. Keep bends to a minimum and use as large as radius as possible. Minimum internal radius is 10”(250mm). Bends can be straightened if required. - 14 - INST 396 Jacuzzi® J-HN Series Heater V12-16... - Page 16 The flue should be bracketed at intervals of 1 M using standard 5” (125 mm) standoff brackets available at most plumbing suppliers. - 15 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

-

Page 17: Wall Terminations

Locate flue cowl onto reduced end of the gal outer covering / flue pipe. Attach with rivets / screws to hold into place. Ensure a drain hole in the cowl is facing down. The flue pipe must slope slightly towards the cowl for the last horizontal run (approx 2º) to allow condensation to drain. - 16 - INST 396 Jacuzzi® J-HN Series Heater V12-16... - Page 18 - 17 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

-

Page 19: Clearances

Venting and flue connections installation must conform to local regulations. Care must be taken to provide the correct ventilation and correct flue connections materials in close proximity to combustible surfaces. - 18 - INST 396 Jacuzzi® J-HN Series Heater V12-16... - Page 20 Do not store chemicals or fuel in the same room as the gas heater. This may cause fire or explosion. When installing in a garage the Jacuzzi® J-HN Series Heaters must be installed 17”(450mm) above floor level. OUTDOOR VENTING INSTALLATION-DIAGRAM AND CLEARANCES - 19 - INST 396 Jacuzzi®...

- Page 21 HORIZONTAL OR VERTICAL VENTING (CATEGORY III) REQUIREMENTS: The heater requires the use of a Jacuzzi® J-HN series indoor vent adaptor kit to adapt the built-in stackless vent for use with 5” (125mm) category III vent pipe. The maximum vent run must not exceed 50 ft of equivalent straight vent pipe. pipe for all models except HiNRG 400 Propane where Max Vent run for HiNRG 400 Propane is 28 feet( 8.5 meters)

- Page 22 PRESSURE VENTS The Jacuzzi® J-HN series heater is a category III gas appliance which requires the use of approved/listed Category III vent pipe and fittings. The heater is a semi-premix burner, forced-draft design which uses positive pressure to force flue gases through the vent pipe to the outside.

- Page 23 Be installed with at least 3 in. and at most 12 in. of clearance from outside of wall (refer to vent manufactures instructions). For US , allow a minimum, of 3 feet (1 m) vertical clearance from terminal to a roof/deck overhang. - 22 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

- Page 24 10 feet (3 meters) from the Vent Cap (vent terminal). In Canada, the vent terminal (Vent Cap) must have a minimum clearance of 4 feet (1.2m) form any gas meters, gas regulators, electric meters, or similar equipment. - 23 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

-

Page 25: Indoor Installation

– up ventilation system which used a blower to force air to proximity of heater installation (Tjernlund is one manufacturer of Listed air make-up systems). - 24 - INST 396 Jacuzzi® J-HN Series Heater V12-16... -

Page 26: Electrical Connection

This appliance must be installed and electrically grounded and bonded in accordance with local regulations and the latest edition of the National Electrical Code (NEC), NFPA 70 for US installations. - 25 - INST 396 Jacuzzi® J-HN Series Heater V12-16... -

Page 27: Gas Connection

Gas valves are pre-set and should only be adjusted by trained Jacuzzi technicians or qualified gas fitters. Propane (LPG) is heavier than air and will pool in low spots. Do not place heater in a pit or other locations where leaking gas might collect as this can lead to an explosion. -

Page 28: Water Pressure Switch Adjustment

WATER PRESSURE SWITCH ADJUSTMENT The Jacuzzi® J-HN Series Pool Heater incorporates a water pressure switch which allows the burner to operate only when the circulating pump is operating. The pressure switch is designed to operate with the heater installed up to 10’ feet above or below the surface level of the pool or spa. -

Page 29: Fitment Of Pressure Relief Valve

If pressure switch cannot be adjusted correctly. DO NOT OPERATE THE HEATER, contact Jacuzzi® or an Authorised Service Agent for advice. If heater is more than 5 feet (1.5 METERS) above or more than 1 foot (300MM) below the level of the pool/spa water line (measured from pressure switch to water line), you are exceeding the range of the pressure switch and a FLOW SWITCH MAY BE REQUIRED. - Page 30 Fan continues to run on high speed 30 seconds later a reattempt for ignition occurs Maximum of 3 ignition attempts occurs After which ignition pack locks out. HEADER CONVERSION TO LEFT HAND HEADER INLET/OUTLET - 29 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

- Page 31 JOB TORQUE SETTING 1.8 FT/IBS (2.5±0.1Nm): REMOVE IN/OUT HEADER COVER PLATE TOP AND BOTTOM REMOVE 8X HEX HEAD BOLTS WITH CLICK TYPE TORQUE WRENCH WITH 7/8” SOCKET JOB TORQUE SETTING 2.6 FT/IBS (3.6±0.2 Nm): - 30 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

- Page 32 JOB TORQUE SETTING 1.8 FT/IBS (2.5±0.1Nm): REMOVE RETURN HEADER COVER PLATE REMOVE 8X HEX HEAD BOLTS WITH CLICK TYPE TORQUE WRENCH WITH 7/8” SOCKET JOB TORQUE SETTING 2.6 FT/IBS (3.6±0.2Nm): - 31 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

- Page 33 JOB TORQUE SETTING 1.8 FT/IBS (2.5±0.1Nm): INSTALL LEFT HAND SIDE MANIFOLD USING 8X HEX HEAD BOLTS WITH CLICK TYPE TORQUE WRENCH WITH 7/8” SOCKET JOB TORQUE SETTING 2.6 FT/IBS (3.6±0.2 Nm): - 32 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

- Page 34 ATTACHE RETURN HEADER COVER PLATE USING A PISTOL CLUTCH TYPE TORQUE CONTROL SCREWDRIVER , SCREW 10 X SCREWS FROM IN/OUT HEADER COVER PLATE BOTTOM JOB TORQUE SETTING 1.8 FT/IBS (2.5±0.1 Nm): - 33 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

-

Page 35: Testing Gas Pressure

>10” WC (HIGH FIRE) BURNER OPERATING 2.6” 8” 2.5” 8” (HIGH FIRE) CO LEVELS (ppm) 10 to 30 max 10 to 30 max 10 to 30 max 10 to 30 max - 34 - INST 396 Jacuzzi® J-HN Series Heater V12-16... -

Page 36: Performance Details

Shut off gas supply and call for service Heat exchanger scaled Shut off gas supply and call for service IGNITION MODULE LED FLASH CODE If the heater cannot be made to perform correctly, please contact the www.Jacuzzipool.com - 35 - INST 396 Jacuzzi® J-HN Series Heater V12-16... -

Page 37: Maintenance Of Your Pool Heater

Important note: Regular maintenance is important to ensure long life and trouble free performance of your pool equipment. If unable to perform the maintenance yourself, contact your local Jacuzzi office who will arrange a trained service technician to perform the maintenance for you. - Page 38 For warranty information please visit www.jacuzzipool.com - 37 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

- Page 39 - 38 - INST 396 Jacuzzi® J-HN Series Heater V12-16...

Need help?

Do you have a question about the J-HN250C and is the answer not in the manual?

Questions and answers