Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for MERELLO ME-104

- Page 1 MATTRESSES WRAPPING MACHINE ME 104 INSTALLATION, USER AND MANTENIANCE MANUAL...

- Page 2 20, nave 23 PINTO – 28320 – MADRID - SPAIN Declare that the product: mattresses wrapper machine ME-104 s/n 1139 Has been developed in accordance with the European Directive 98/37/CE (22nd June 1.998) and shows compliance with the Normative EN414. EN292,...

-

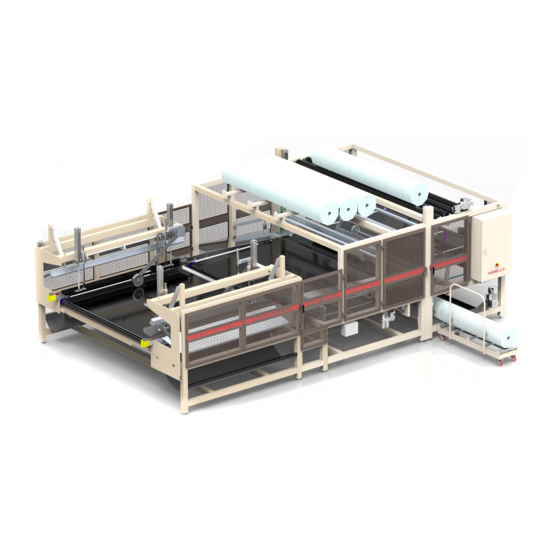

Page 3: General Machine Description

This way, a half-wrap mattress waits for the sealing of the previous. The machine complies with safety requirements of CE as expressed on last chapter TECHNICAL DATA AERIAL NOISE: 70 dB(A) WEIGHT MODULE 1: 1.400 Kg WEIGHT MODULE 2: 800 Kg WEIGHT MODULE 1: 1.600 Kg INSTRUCTION MANUAL ME-104... -

Page 4: Installation Procedure

It is possible to activate an external relay (24Vdc) parallel to it (between Y15 and 0V) • SYNCHRONIZING WITH FOLLOWING LINES: the mattress will not leave the INSTRUCTION MANUAL ME-104... - Page 5 After these adjustments, press the START/STOP button to put the machine ready to work Please note that the machine will not work while any of the doors stay opened or the emergency stop is pressed. The screen and lights will indicate this situation INSTRUCTION MANUAL ME-104...

- Page 6 ME-104: PLASTIC FILM INSTALLATION INSTRUCTION MANUAL ME-104...

- Page 7 By pressing the EMERGENCY STOP or pulling the EMERGENCY WIRE the energy is removed from the actuators, every movements of the machine are cancelled and the machine status is moved to STOP. After release it, the energy appears again but the machine remain INSTRUCTION MANUAL ME-104...

- Page 8 • Red light blinking: emergency stop is pressed or emergency wire is pulled or a door is opened or an alarm has occurred. The screen shows the status • Red light steady: emergency has been eliminated, but the machine is not working until START/STOP will be press INSTRUCTION MANUAL ME-104...

- Page 9 When they are half used up, silicone sprayed could help to last longer. For covers substitution, please use self-adhesive 0,15 mm thick Teflon fabric • REPARATION OF RODLESS CYLINDERS: REPAIR KIT 1. air connection 2. end caps 3. out seal strip 4. inner seal strip 5. shuttle INSTRUCTION MANUAL ME-104...

- Page 10 In order to keep the same strenght on every roll, is very recommendable to reduce the rolls speed a little. This way, the coneyor will help for unwinding the rolls, avoiding different speeds Also, the parameter ‘Time retro roller’ can be increased with the same purpose INSTRUCTION MANUAL ME-104...

-

Page 11: Touch Screen

• Error on phase 2: the wrap of the mattress exceeds the time limit. After check the problem, move the mattress up to pass the sealing bar (F3 key) and press STAR/STOP button to resume the cycle • Technical stop: contact technical service INSTRUCTION MANUAL ME-104... - Page 12 2nd module release before seal, to avoid wrinkles. When AFTER (and PRESS M2) are activated, the wheels keep connected to ensure that the mattress is not catch by the sealing bar. • ALTERNATE BUTTON RAMPS: when activated, the ramps on the 2 module ascend INSTRUCTION MANUAL ME-104...

- Page 13 • DELAY PRESS M2: time in tenth of seconds during which the wheels over conveyor in Module nº2 wait to push on the mattress to assure the traction. This permit the mattress to start advance during wrapping. Aprox.: 10-20 INSTRUCTION MANUAL ME-104...

-

Page 14: Measures Menu

A bigger value provokes the mattress to advance more. The right value makes the mattress to stop in the beginning of the module nº3. Aprox.: 200-300 INSTRUCTION MANUAL ME-104... -

Page 15: Heating Menu

The amount of power can also be regulated in the control cabinet P1. Valor aprox.: 25-50 NOTES: The grosser the film is, the lower this value must be Too high power values will reduce the Teflon covers life Too low values will increase the cycle time INSTRUCTION MANUAL ME-104... - Page 16 Aprox.: 10 • GAIN F: value (center and sides) that decreases the simulated temperature while not heating. It is apply each two seconds subtracting a division of the value (Temp/value) from the simulated temperature. Aprox.: 8-15 TEST MENU: INSTRUCTION MANUAL ME-104...

- Page 17 Give access to every output on the PLC, for monitoring and modify (some of them need to put the PLC in STOP mode to be accepted). Useful for maintenance actions INSTRUCTION MANUAL ME-104...

-

Page 18: Instructions For Safety

♦ The seals are achieved by heating. The wrong use of the bars can cause burn on hands or arms The machine is intended for wrapping mattresses. The use for wrapping other kind of things ♦ can result in injuries or accidents INSTRUCTION MANUAL ME-104... -

Page 19: Part List

RU2L Nylon wheel Ø200 UCPA206 Bearing bridge type UCP 206 UCFL205 Bearing flange type UCFL 205 PLACA3F Steel fix ramp Polyurethane plate for waste BANDA3 Conveyor belt PVC NSL-10ELAV 2250X4035 (4635 p/EXTRA WIDE) PLACA3M Steel movable ramp INSTRUCTION MANUAL ME-104... - Page 20 Guards sealing bar lateral side CIL11 Cylinder Univer ISO 40 400 D.M CIL7 Cylinder Univer ISO 40 320 D.M UCPA206 Bearing bridge type UCPA 206 Motoreducer Bonfiglioli VF44 P1 20 P71 B14 B3, 0,37KW i=20 Switch detector with Ø45 wheel INSTRUCTION MANUAL ME-104...

- Page 22 INSTRUCTION MANUAL ME-104...

- Page 23 INSTRUCTION MANUAL ME-104...

-

Page 24: List Of Materials

LIST OF MATERIALS Reference Description magneto thermal breaker 1p 6A A2,A3 magneto thermal breaker 1p 25A Resistance 1 Ohm 40W differential breaker 2p 40A, 30 mA main breaker 2p 40 A fuse Φ10, 25A programable controler Mitsubishi FX1N 40MTDSS 16XY Output module Mitsubishi FX1N16YET c1-c2 Contactor 24 VDC 25 A... - Page 25 X11 DOOR M1d C 32 X20 DOOR M2 X21 CENTRAL BAR DOWN X22 SIDE BAR RETURN X23 PRESS M3 DETECTOR X24 PRESS M3 COUNTER L6 EMERGENCY CABLE L7 EMERGENCY CABLE X15 UPPER ROLL LEVER X17 EMERGENCY STOP INSTRUCTION MANUAL ME-104...

- Page 26 Y5 UPPER ROLL RETRO Y7 CONVEYOR 3 ADV Y10 CONVEYOR 3 FAST Y11 CONVEYOR 2 ADV Y13 CONVEYOR 1,2 FAST 0V 24V COM5 GREEN LIGHT YELLO LIGHT RED LIGH X16 START/STOP INPUT X26 CUT C INPUT X27 SEAL C INPUT INSTRUCTION MANUAL ME-104...

- Page 27 +V1, +V2 OPEN BARRIER WHEELS M1 BLOWER M1 ev-S DOWN CENTER WHEELS M2 CUTTER CENTRE RAMPS UP DOWN SIDES CUTTER SIDES ev10 DOWN PRESS ev11 BLOQUATE PRESS ev12 BLOQWER M3 ev13 APPLY POWER C APPLY POWER L INSTRUCTION MANUAL ME-104...

Need help?

Do you have a question about the ME-104 and is the answer not in the manual?

Questions and answers