Subscribe to Our Youtube Channel

Summary of Contents for Compur Monitors Statox 503

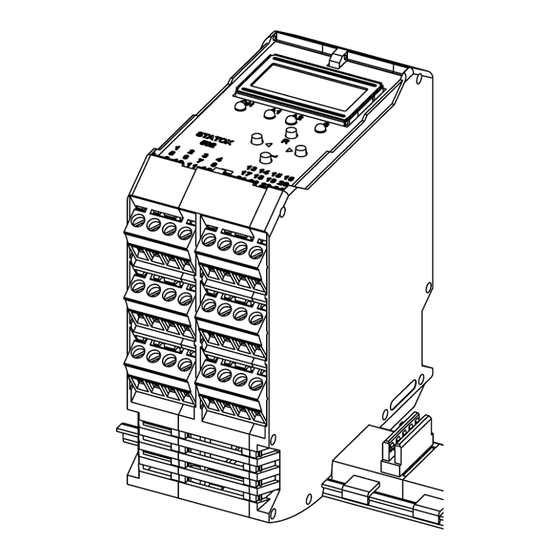

- Page 1 Manual Statox 503 Control Module Compur Monitors GmbH & Co. KG Weissenseestrasse 101 D-81539 München Phone: +49 (0) 89 62038 268 Fax: +49 (0) 89 62038 184 www.compur.com compur@compur.de...

-

Page 2: Table Of Contents

Statox 503 Control Module Content Warning Signs ............................4 Mounting .............................. 6 Dismounting ............................7 Connecting to power supply ......................... 8 Start-up ..............................8 Controls ............................... 10 LEDs ..............................10 Display ..............................11 Communication bus ..........................12 Electrical connections ......................... 12 Connecting the external reset and analog output .............. - Page 3 Statox 503 Control Module Livetime ............................42 Operating the Statox 503 with Statox 501 ARE or HRC Sensor ............ 43 Issue 10 / 2018 Page 3 of 46...

-

Page 4: Warning Signs

Read and observe this manual prior to installation and start-up. The Statox 503 Control Module is only allowed to operate under the given ambient conditions (see Technical Data). In particular, it must not be operated in potentially explosive atmospheres! The Statox 503 Control Module must be operated, maintained and repaired by trained and expert ... - Page 5 Zone 1 or 2. The Statox 503 can also be operated as Common Alarm Module. It collects the alarm signals (A1/A2/SF) of up to 25 connected control modules and generates a common alarm on LEDs, relays and its analog output.

-

Page 6: Mounting

Statox 503 Module must be at least 80 mm (3.15 “). Furthermore at least 120 mm (4.72 “) must be remain free between two rail lines. -

Page 7: Dismounting

Statox 503 Control Module You can combine modules of the Statox 503 series in any sequence. Adding or removing one module has no impact on the others. You can save wiring effort starting with the power supply on the outside and connecting it to the bus with the bus plug. -

Page 8: Connecting To Power Supply

Otherwise the sensor can be damaged. Ex works the Statox 503 is configurated to operate as Control Module. After connection to power, it performs a self-test. It displays the firmware version, then for 5 seconds the actual measuring program, then “PLEASE WAIT”. - Page 9 Statox 503 Control Module If a sensor head has been connected and the appropriate program has been selected, the measuring mode will start. Sensor heads for combustible gases, type HRC, ARE, LC IR, MCIR, CO and PID must be calibrated after being connected.

-

Page 10: Controls

Right display line when in the measuring mode. In some menus a continuous push activates the fast mode LEDs The Statox 503 has 4 status LEDs. The function of the individual LEDs is subsequently explained. Description Function Power supply: Green „ON“... -

Page 11: Display

Statox 503 Control Module Display In the measuring mode the display shows the target gas, the actual measured value and the unit. Example 1 (Combustible gas) Measured value Unit in % LEL (Lower Explosion Level) Example 2 (Toxic gas) Unit in ppm (parts per million) Measured value In case of an over range exposure, the full scale value is going to flash. -

Page 12: Communication Bus

Figure 6: Bus terminals Electrical connections The Statox 503 operates at 24 ± 2 VDC. Higher voltage or short circuits on the terminals may destroy the module. The terminals are pluggable. To remove the terminal blocks, set the screwdriver directly over the screws and press the block to the front side. - Page 13 Statox 503 Control Module Terminal Contact Function 1 External Reset Remote Reset 2 GND (External Reset) 3 0 – 22 mA analog output Analog output 4 GND (0 - 22 mA output) (must be short – circuited if not in use)

-

Page 14: Connecting The External Reset And Analog Output

Statox 503 Control Module Connecting the external reset and analog output A GND-signal on terminal 1 initiates a reset just as pushing the RESET button. The analog output generates a current analog to the actual measured value with 4 mA corresponding to zero and 20 mA to end of scale. -

Page 15: Connecting The Internal Relays

Statox 503 Control Module Connecting the internal relays Statox 503 has three relays, each equipped with one make and one break contact. Two relays monitor alarm threshold exceeding, one system failure. System failure relay: The SF-relay coil is always active and drops out in case of a system failure or voltage drop. -

Page 16: Password

Statox 503 Control Module Statox 503 main menu Password The main menu is password protected. No matter if in the measuring, the failure or the start mode: below procedure gives access to the main menu. The password is: 1994 (not changeable) -

Page 17: Main Menu Structure

ALARM 2 RELAY Setting Alarm 2 relays parameters no access if the Statox 503 is operated as Common Alarm Module. no access if a program for the operation of a 4 – 20 mA transmitter is active. „MENU NOT ACTIVE“ will be shown for 2 s if a menu is not accessible in the actual mode or program. -

Page 18: Service Mode

The sensor heads for toxic gases, oxygen or combustible gases measure the concentration of the target gas in the field. Statox 503 evaluates the signal and displays the value. Any alarm threshold exceeding is signaled by an LED and the alarm relays is activated. The alarm is also communicated on the bus. - Page 19 Statox 503 Control Module MEASURING MODE Change Menu item Active program Select new program, no Time-Out! no change of program Displayed for 2 sec New program number. Push ENTER to start. Start-up Figure 13: Program selection diagram 1. Push the - button to enter the „CHOOSE PROGRAM“...

-

Page 20: Calibration

Statox 503 Control Module Calibration In this menu you can perform a calibration of sensor heads type Statox 501 HRC, ARE, LCIR, MCIR, CO PID detecting combustible gases, carbon dioxide (CO ) and volatile organic compounds (VOC). The test gas concentration must be within the permitted range, see program list. - Page 21 Statox 503 Control Module 1. Enter the menu „CALIB. ROUTINE“ by pushing 2. The display shows: „ZERO ADJUSTM.“ Beginning with step 3, the automatic Time-out is not active. 3. Push the - button. Display: „000“ flashing. The Control Module adjusts the actual zero point.

-

Page 22: Reading The Bridge Voltage

Statox 503 Control Module c) Display „DONE“: The calibration was successful. After 2 s the display changes. 12. The display will now show the actual measured value with unit. In order to avoid unrequested alarms make sure the signal created by the test gas has dropped below the alarm threshold prior to returning into the measuring mode. -

Page 23: Switching The Sensor Power Supply Off

Statox 503 Control Module 1. Enter the menu „BRIDGE VOLTAGE“ by pushing in the main menu. 2. With ◄- or ► you can navigate between the display modes.. During this procedure the automatic time-out is 60 min. 3. Push Reset to return to the main menu and again to return to measuring mode. -

Page 24: Programming The Alarm Relays

Statox 503 Control Module 1. Enter the menu „SENSOR POWER“ by pushing 2. Display „SENSOR ON“. Up to step 7 the automatic time-out is not active. 3. Change the status of the sensor head power supply with ◄ or ►. - Page 25 Statox 503 Control Module MEASURING MODE Figure 17: Control Module - alarm relays setting 1. Enter the menu „ALARM 1 RELAY“ or „ALARM 2 RELAY“ by pushing The procedure is identical for both relays. With the next alarm the new settings will be effective.

- Page 26 Statox 503 Control Module Statox 503 in Common Alarm Module Operation The ex-works setting of the Statox 503 is Control Module mode. See chapter 8.3 for changing to Common Alarm mode. After being connected to power, the Statox 503 performs a self-test. Then the display shows the actual firmware code.

-

Page 27: Alarm Relays Configuration

Statox 503 Control Module Example: On the bus are 3 control modules and 1 common alarm module. The first control module is in alarm 1 status, the second control module is in alarm 2 status, and the third control module submits system failure. All LEDs and relays on the common alarm module will be activated, the analog output will generate 16 mA, and the display will show „COMMON ALARM 2“. -

Page 28: Functional Test

7. The module returns now automatically into the main menu. 8. Push the reset button to return to the measuring mode. Common menu items of the Statox 503 Functional test This test can be performed in any operation mode (Control Module or Common Alarm Module). It tests the proper function of the LEDs, relays, analog output and bus. - Page 29 Statox 503 Control Module MEASURING MODE Change Menu item LED A1 flashes, Relay A1 switches, alarm report A1 to bus LED A2 flashes, Relay A2 switches, alarm report A2 to bus LED S flashes, Relay SF switches, alarm report SF to bus...

-

Page 30: Current Output In Service Mode

Statox 503 Control Module Current output in Service Mode You can select which current the analog output generates in the service mode. The ex - works setting is 2 mA. The selected output current is conserved independent from selected program or operation mode. -

Page 31: Changing The Operation Mode - Control Module Or Common Alarm Module

Statox 503 Control Module Changing the operation mode – Control Module or Common Alarm Module The ex - works setting of the Statox 503 is Control Module. Please find detailed information for running the Statox 503 in Control Module mode in chapter 6. - Page 32 VOC. Statox 501 HRC, ARE, LCIR, MCIR, CO Together with the two internal resistors of the Statox 503 module the sensor forms a Wheatstone measurement bridge. A gas concentration-dependent resistor in the sensor leads to a change of the bridge voltage.

- Page 33 Statox 503 Control Module Sensor head type Signal Measuring mode Cable Statox 501 HRC, ARE, Voltage in mV: LCIR, MCIR, CO Voltage mode 3 or 5 Figure 25 non balanced bridge Statox 501 PID Statox 501/S, Current: 4 – 20 mA...

-

Page 34: Status Messages

Statox 503 Control Module 10 11 12 21 22 23 24 (optional) 5 Figure 26: Connecting the Statox 560 Status- and error messages In case the display stays dark, check the polarity and the voltage of the power supply. The internal fuse may be damaged. - Page 35 Statox 503 Control Module Meaning Upper Display Line Lower Display Line Zero adjustment Zeroing Zero found, apply span gas Span gas detected Plateau found Enter span gas concentration (value) (unit) Enter response factor Menu finished Measurement during calibration routine (value)

-

Page 36: Error Messages

Statox 503 Control Module Error messages Many internal and external functions of Statox 503 are monitored for proper function. It can differentiate between critical and non - critical malfunctions. While critical errors always set the output current to zero, activate the system failure alarm relay and the LED „S“. Non - critical errors (such as operating errors during calibration, e.g. - Page 37 Statox 503 Control Module Display Nature Description Measures ERROR 15 Critical Hardware defective Contact your Compur service partner. Check gas concentration and response factor The result of entry. Eventually select another span gas concentration. gas concentration x response factor CONC Critical Push the Enter button and try again.

-

Page 38: Control Module - Status Diagram

Statox 503 Control Module Control Module - Status diagram LEDs Relays System Current Input from Sensor Display or transmitter signal Status output 4-20 mA or Normal 4 – 20 mA Measuring value OFF active active active bridge voltage 4-20 mA or... -

Page 39: Safety Functions

Safety Function 1 (SF1) The Statox 503 Control Module monitors a 0–22 mA input signal, translates it into a concentration on the display, and provides it as an analog 0 - 22 mA current output signal. It also operates as a power supply for the sensor head. -

Page 40: Diagnostic Time And Measuring Cycle

Safety Function 2 (SF2) The Statox 503 Control Module monitors the analog 4 – 20 mA signal and detects exceedings of the programmable alarm thresholds with the relays A1 and A2. It is also the power supply of the sensor head. -

Page 41: Installation And Parameter Settings

Statox 503 Control Module Installation and Parameter Settings In order to maintain the specified PFD and SFF rates, the following measures must be taken! An external alarm device must be connected to SF relay! The output signal in the service mode must be set to 2 mA, in order to differentiate between service and measuring mode. -

Page 42: Average Probability Of Failure On Demand

(see IEC 61508-2, Table 3). Livetime The livetime of Statox 503 is expected to be 10 years. Above failure rates are applicable within this time interval. After 10 years these data might be too optimistic. Page 42 of 46... - Page 43 At a hardware failure tolerance of 0 and 6 month prooftest interval SIL 2 compliance is given for ARE/HRC sensors (see IEC 61508-2, Table 2). A prooftest of a Statox 501 ARE / HRC sensor head must be done together with the connected Statox 503 control module. For this test, span gas must be used.

- Page 44 Statox 503 Control Module Technical Data Product name: Statox 503 Control Module Manufacturer: COMPUR Monitors GmbH & Co. KG, D-81539 Munich Power supply: 24 ± 2 VDC max. 200 mA Power consumption: max. 5 W Current rating: max. 8 A on communication bus Operating temperature: -10°...

- Page 45 Statox 503 Control Module Declaration of conformity Issue 10 / 2018 Page 45 of 46...

- Page 46 Any statement or recommendation not contained herein is unauthorized and shall not bind Compur Monitors. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or device or its use. No license is implied or in fact granted under the claims of any patent.

Need help?

Do you have a question about the Statox 503 and is the answer not in the manual?

Questions and answers