Summary of Contents for Moteurs Baudouin PowerKit 6M16 Series

- Page 1 Operation and Maintenance Manual for PowerKit 6M16 Series Operation and Maintenance Manual for PowerKit 6M16 Series 1 of 40...

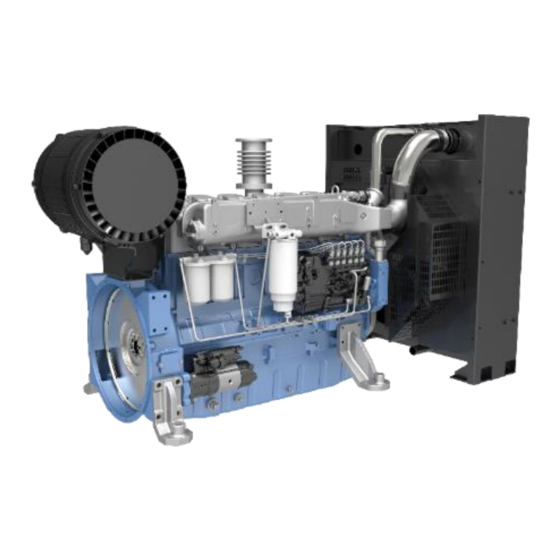

- Page 2 Operation and Maintenance Manual for PowerKit 6M16 Series Dear Customer, Thank you for choosing a Baudouin PowerKit engine! This series has a compact structure, reliable operation, excellent performance, low fuel consumption and meets the requirements of international emission standards. The engine is quick to start, simple to operate and easy to maintain.

- Page 3 Operation and Maintenance Manual for PowerKit 6M16 Series Notice 1. Before delivery, this series of diesel engines have already been tested, strictly following the test specification. Therefore, never dismantle the lead sealing on the throttle to raise its openness. Never dismantle or impact the rotor of turbocharger which belongs to the sophisticated parts;...

- Page 4 Operation and Maintenance Manual for PowerKit 6M16 Series Safety 4 of 40...

- Page 5 Operation and Maintenance Manual for PowerKit 6M16 Series Before maintenance and repair, please notice that: ◆Avoid repeated exposure to used oil for a long time. ◆ If possible, wear protective clothing and waterproof gloves. ◆Do not keep oil-soaked rags in the pocket.

-

Page 6: Table Of Contents

Operation and Maintenance Manual for PowerKit 6M16 Series Contents 1.Structure and parameters of the diesel engine ..................7 1.1Model Meaning of the diesel engine ................... 7 1.2 External dimensions and structure of the diesel engine ............. 7 2. Brief introduction of main systems of the diesel engine ............... 7 Gear train and valve mechanism.................... -

Page 7: Structure And Parameters Of The Diesel Engine

Operation and Maintenance Manual for PowerKit 6M16 Series 1.Structure and parameters of the diesel engine 1.1Model Meaning of the diesel engine 1.2 Main technical parameters of the engine Items Unit Parameters In line, watercooled, 4-stroke, DI, turbocharged and — Engine type intercooled —... -

Page 8: Lubrication System

Operation and Maintenance Manual for PowerKit 6M16 Series 1-crankshaft timing gear; 2-intermediate gear; camshaft timing gear; 4-air compressor gear; 5-injection pump gear; 6-oil pump intermediate gear; 7-oil pump gear Figure 2-1 Gear train transmission diagram 2.1.2 Adjustment of valve clearance... - Page 9 Operation and Maintenance Manual for PowerKit 6M16 Series including 15W40, can be used within the specified temperature range. At occasional low temperature, the engine oil can be preheated by taking appropriate measures, or replace the engine oil suitable for the ambient temperature.

-

Page 10: Fuel System

Operation and Maintenance Manual for PowerKit 6M16 Series Forced lubrication: The engine oil from the oil pan passes through the oil strainer and then is pumped into the oil filter and oil cooler by the oil pump, and finally arrives at the positions need to be lubricated through the oil line system. - Page 11 Operation and Maintenance Manual for PowerKit 6M16 Series 1. O-ring; 2. Gasket; 3. Fuel return hole of injector Figure 2-4 Fuel return method Internal fuel return through the cylinder head is adopted for6M16 four-valve diesel engine for power generation (figure 2-4). In this manner, the injector mounting hole is located in the cylinder head, so it should be ensured that fuel return is completely free of leakage.

-

Page 12: Cooling System

Operation and Maintenance Manual for PowerKit 6M16 Series Recommended 5-step method for tightening the fuel inlet joint: 1) Insert the injector into cylinder head. Ensure that the injector is correctly placed and contacts with the seal ring correctly, and then tighten the clamping bolt of injector to 3Nm. -

Page 13: Electrical Units

Operation and Maintenance Manual for PowerKit 6M16 Series Expansion tank Oil cooler Water tank Figure 2-5 Circulation of cooling system For the 6M16 four-valve diesel engine for power generation, there is a water drain hole is designed at the oil cooler cover (figure2-6). - Page 14 Operation and Maintenance Manual for PowerKit 6M16 Series diagram of the alternator. Figure2-7 Precautions during installation and wiring of the alternator: a) It should be fully cooled; b) It must be dust-proof, splash-proof and oil-proof; c) Check the tension of alternator belt;...

-

Page 15: Installation And Use Of The Diesel Engine

Operation and Maintenance Manual for PowerKit 6M16 Series Figure 2-8 shows the circuit diagram of the starter. Wiring terminals of the starter: 30 connected to the anode of battery; 31 connected to the ground; 50 connected to the solenoid switch. -

Page 16: Hoisting Of The Diesel Engine

Operation and Maintenance Manual for PowerKit 6M16 Series 4) Spray solvent into the turbocharger intake/exhaust ports until the oil sealing oil is completely removed. 5) Add oil to the oil pan as required. 6) Add coolant to the engine cooling system. The coolant should be softened fresh water containing anti-freeze additives. -

Page 17: Preparations Before Starting The Diesel Engine

Operation and Maintenance Manual for PowerKit 6M16 Series prevent water and pollutant from entering the diesel engine. 3.3.3 Installation of exhaust system The external exhaust pipe must be steel pipe avoiding excessive bends, and it should be firmly fixed. No vibration of such pipe is allowed, and it shall not impose any force on the expansion pipe of the diesel engine. -

Page 18: Starting Of The Diesel Engine

Operation and Maintenance Manual for PowerKit 6M16 Series 3) Check the engine oil level The engine oil level of oil pan should be in between the upper and lower scale lines of dipstick. Add oil from the oil filler port if necessary. -

Page 19: Operation Of Diesel Engine In Winter

Operation and Maintenance Manual for PowerKit 6M16 Series rated speed. After unloading, the diesel engine should run at idle speed for 1 to 2 minutes before shutting down. 5) During operation, pay attention to the following parameters and the related places: Main oil passage pressure: (350~580) kPa;... -

Page 20: Power Definition And Usage Conditions Of Diesel Engine For Land Power Generation

Operation and Maintenance Manual for PowerKit 6M16 Series for (1~2) minutes, and wait for a while until the water temperature and oil temperature lower down; the coolant containing antifreeze additives should not be drained out after shutdown. However, if the coolant contains no antifreeze additive, make sure to open the drain valves or drain plugs on the engine block and oil cooler cover to fully drain off the coolant to prevent the engine from being frost cracked. -

Page 21: Maintenance Of The Diesel Engine

Operation and Maintenance Manual for PowerKit 6M16 Series Table 3-1 Running condition sand applications of different powers of diesel engine Power Running conditions Applications category 1. Unlimited running time for every year; Be possible to run under 2. Running with constant 100% of rated load;... - Page 22 Operation and Maintenance Manual for PowerKit 6M16 Series The fuel used must conform to the requirements specified in section D.1 of Appendix D to the national standard GB 20891-2014. 4.1.2 Lubricating oil For Baudouin Power industrial diesel engine, grade CF-4 lubricating oil shall be use. See Table 4-1 for details.

- Page 23 Operation and Maintenance Manual for PowerKit 6M16 Series 4.1.3 Coolant The diesel engine cooling system must be filled with pure coolant. The coolant can be used to prevent freezing under cold weather and to prevent boiling under high temperature. Furthermore,...

-

Page 24: Routine Maintenance Of The Diesel Engine

Operation and Maintenance Manual for PowerKit 6M16 Series Table 4-6 Application of sealant for diesel engine Grade Major application Supplements Application part Flywheel housing bolt Camshaft thrust plate bolt Camshaft timing gear bolt Applied onto the Intermediate idler gear bolt... - Page 25 Operation and Maintenance Manual for PowerKit 6M16 Series 5) Check the oil pressure of diesel engine; 6) Check the connector and wire connection; 7) Check the water temperature of diesel engine; 8) Check the temperature and color of exhaust gas, sound, vibration and speed of diesel engine.

- Page 26 Operation and Maintenance Manual for PowerKit 6M16 Series Figure4-2Checking of oil level Check the fuel level Check the fuel level indicator on dashboard and add fuel if necessary. Check the engine for water, gas and oil leakages Check the fan Visually check the fan blade for damage, and check the connecting bolts.

- Page 27 Operation and Maintenance Manual for PowerKit 6M16 Series Check the belt tension The belt is automatically tensioned by the ten sioner. You can check the tension of belt by pushing the belt with hand. Figure 4-4 Check the color of exhaust ...

-

Page 28: Regular Maintenance Of The Diesel Engine

Operation and Maintenance Manual for PowerKit 6M16 Series 4.3 Regular maintenance of the diesel engine Table 4-7Maintenance items of the diesel engine Routine Maintenance item First inspection inspecti ● ● ● ● ● ● Replace diesel engine oil ● ●... -

Page 29: Maintenance Of The Diesel Engine For Long-Term Storage

Operation and Maintenance Manual for PowerKit 6M16 Series 4.5Maintenance of the diesel engine for long-term storage 4.5.1 Oil sealing method Add lubrication system corrosion inhibitor to the lubricating oil. Start the engine and then stop it after running for (5~10) minutes. Remove the original diesel fuel inlet pipe and insert it into the barrel containing sealing oil for fuel system. -

Page 30: Common Faults And Troubleshooting

Operation and Maintenance Manual for PowerKit 6M16 Series Figure 5-1 Figure 5-2 (3) Cylinder deactivation method: Generally, cut off the fuel supply to the suspect malfunctioned cylinder, and compare the working condition of the diesel engine before and after stopping fuel supply to narrow down the scope for further determination of the malfunction location or cause. - Page 31 Operation and Maintenance Manual for PowerKit 6M16 Series High-pressure fuel pipe damaged or Repair or replace. there is fuel leakage Check the sealing of valve and cylinder gasket and check for Insufficient compression pressure in cylinder worn piston rings. Repair or replace the faulty parts if any.

- Page 32 Operation and Maintenance Manual for PowerKit 6M16 Series 5.2.2 Engine stopped soon after startup Cause Troubleshooting Check the fuel pipe and its joint for leakage. Check whether the bleeder screw is securely tightened. Expel the air out of the fuel Air trapped in fuel system system.

- Page 33 Operation and Maintenance Manual for PowerKit 6M16 Series 5.2.4 Excessive fuel consumption Cause Troubleshooting Check the air filter and intake pipe for clogging. Intake system clogged Remove clogging if any Check the exhaust pipe and brake valve for clogging. Exhaust back pressure is too high...

- Page 34 Operation and Maintenance Manual for PowerKit 6M16 Series 5.2.6Engine exhaust gas is white or blue Cause Troubleshooting Replace fuel. Poor fuel quality with excessive moisture Check the operating temperature of the thermostat. Coolant temperature is too low Replace it if necessary...

- Page 35 Operation and Maintenance Manual for PowerKit 6M16 Series 5.2.8 Rotating speed is unstable Cause Troubleshooting Clean the fuel system, replace the fuel Poor fuel quality with moisture or wax Check the fuel suction pipe and its joint for tightness. Air is sucked into fuel suction pipe Expel the trapped air.

- Page 36 Operation and Maintenance Manual for PowerKit 6M16 Series 5.2.10 Coolant temperature is too high Cause Troubleshooting Check for leakage. Add coolant. Coolant level in expansion tank is too low Adjust the belt tension in accordance with the Water pump belt is slack requirements.

- Page 37 Operation and Maintenance Manual for PowerKit 6M16 Series 5.2.12 Excessive noise Cause Troubleshooting Replace the fuel The fuel is poor in quality Check the thermostat, and replace it when necessary Coolant temperature is too low Check, repair and adjust Injection nozzle has poor atomization...

- Page 38 Operation and Maintenance Manual for PowerKit 6M16 Series 5.2.15 The alternator does not generate electricity at all Cause Troubleshooting Check the wires of alternator and ammeter and Short circuit or open circuit, connector loosened repair if necessary Rotor or stator coil is short circuit or open circuit, or is...

- Page 39 Operation and Maintenance Manual for PowerKit 6M16 Series 5.2.17 Charging current unstable Cause Troubleshooting The coil of stator or rotor is about to open circuit or short Repair or replace circuit Repair Poor contact of electric brush Repair Loose or poor contact of terminal...

-

Page 40: List Of Diesel Engine Wear Parts

Operation and Maintenance Manual for PowerKit 6M16 Series 6 .List of diesel engine wear parts Name Quantity Cylinder head gasket Turbocharger gasket Exhaust manifold gasket Intake manifold gasket Cylinder head cover gasket Poly-V belt (10PK) Poly-V belt (8PK) Air line connecting hose...

Need help?

Do you have a question about the PowerKit 6M16 Series and is the answer not in the manual?

Questions and answers