Table of Contents

Advertisement

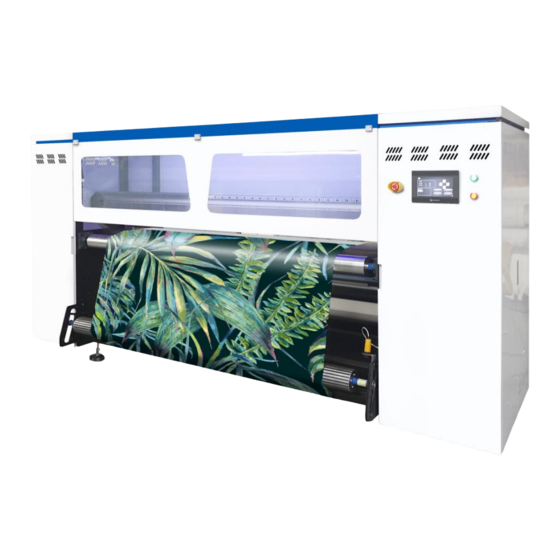

Model S High Speed Sublimation printer

High Speed Sublimation printer

Hangzhou Honghua Digital Technology Stock Co., Ltd.

Address: 3911 Binsheng Road, Binjiang District, Hangzhou

Postal Code (PC): 310052

TEL:+86-0571-88866678

FAX:+86-0571-88852900

E-Mail:honghua@atexco.cn

Website:www.atexco.cn

1

Model S

User manual

Ver 1.0

April, 2019

Advertisement

Table of Contents

Summary of Contents for Atexco S

- Page 1 Model S High Speed Sublimation printer Model S High Speed Sublimation printer User manual Ver 1.0 April, 2019 Hangzhou Honghua Digital Technology Stock Co., Ltd. Address: 3911 Binsheng Road, Binjiang District, Hangzhou Postal Code (PC): 310052 TEL:+86-0571-88866678 FAX:+86-0571-88852900 E-Mail:honghua@atexco.cn Website:www.atexco.cn...

- Page 2 Model S High Speed Sublimation printer Preface Thank you very much for purchasing the Model S series machine. ⚫ In order to ensure the correct and safe use of the product based on a comprehensive understanding of the performance of this product, please read this manual and keep it in a safe place.

- Page 3 Model S High Speed Sublimation printer Ensure safety and proper use • To ensure the safe and proper use of the printer, please read this manual carefully before use. • After reading the manual, keep it in a safe place and refer to it when necessary.

- Page 4 Model S High Speed Sublimation printer Safety guidance Please read the following instructions before using your Model X High Speed Sublimation printer and follow the warnings and instructions marked on the printer: Printer installation considerations WARNING Do not install the printer near solvents such as alcohol or thinner.

- Page 5 Model S High Speed Sublimation printer ▪ Excessively moist and dry places ▪ Direct sunlight rooms ▪ Hot places ▪ Near an open flame or humid places Using the printer in the following places may cause the machine to malfunction or fail •...

- Page 6 Model S High Speed Sublimation printer Make sure the power cord is securely plugged into a power outlet. Doing so may cause a fire or short circuit. Do not use a power cord that is different from the one provided by the printer.

- Page 7 Model S High Speed Sublimation printer Avoid using the socket with the copier or air conditioning system, which are regularly switched between on and off, in the same loop. Avoid using sockets controlled by wall switches or automatic timers. Keep your computer system away from potential sources of electromagnetic interference.

- Page 8 Model S High Speed Sublimation printer CAUTION Take care to prevent internal electrical components from being in contact with metal objects or liquids, as this may result in fire or electric shock. Do not put your hand on the printer while printing.

- Page 9 Model S High Speed Sublimation printer Do not use any lubricant on the parts of the machine. CAUTION At least once a year, remove the power plug from the power outlet, move it and clean up the surrounding area. Accumulated dust can cause a fire hazard.

- Page 10 Model S High Speed Sublimation printer Do not use expired ink as this may cause a malfunction. Dispose of waste ink in accordance with relevant regulations. Be careful not to let ink get into your skin or clothing. If the ink gets to your skin, rinse it off immediately with soap and water.

-

Page 11: Table Of Contents

Model S High Speed Sublimation printer MENU Chapter1 Introduction to High Speed Sublimation printer ................12 1.1 Brief introduction ............................ 12 1.2 Environmental requirements for printer ....................13 1.3 The main features of High Speed Sublimation printer ................13 1.4 Schematic diagram and introduction of the main structure and accessories of High Speed Sublimation printer ................................ -

Page 12: Chapter1 Introduction To High Speed Sublimation Printer

It breaks through the limitations of traditional printing, no color limit, no return limit, so that the designer's design concept is truly reproduced. The high-speed digital paper machine is the latest digital printing equipment in the world, which overcomes the problem of slow printing speed of the original digital tape guide. -

Page 13: Environmental Requirements For Printer

Model S High Speed Sublimation printer 1.2 Environmental requirements for printer The temperature is generally controlled at 25° C~30° C, and the humidity is controlled at 55%~75%RH. Avoid direct exposure of the printer to sunlight, strong light, wind or heat. - Page 14 Model S High Speed Sublimation printer Product model Model S Head type and quantity 4 pieces of Industrial heads Ink type Sublimation Color mode 4 colors Ink color K、 C、M、 Y Transferring Paper Applicable material Production Mode 453m² /h Select the suitable...

-

Page 15: Schematic Diagram And Introduction Of The Main Structure And Accessories Of High Speed Sublimation Printer

Model S High Speed Sublimation printer 1.4 Schematic diagram and introduction of the main structure and accessories of High Speed Sublimation printer Figure 1-1 Figure 1-2... - Page 16 Model S High Speed Sublimation printer Figure 1-3 Figure 1-4 Name Description Precautions To prevent head With print head, sub ink damage, do not touch tank and other carriage when it is Head carriage components installed moving and never leave inside.

- Page 17 Model S High Speed Sublimation printer For safety production, Front cover plate close the cove plate when printing. Let paper smoothly adsorbed on the The paper is adsorbed and platform. Adjust the printed on the platform under head carriage height...

-

Page 18: Chapter 2 Touch Screen Operation Of The High Speed Sublimation Printer

Model S High Speed Sublimation printer Chapter 2 Touch Screen Operation of the High Speed Sublimation printer Figure 2-1 operation flow 2.1 Boot interface After pressing the power button, the front touch screen displays the interface shown in Figure 2-2. - Page 19 Model S High Speed Sublimation printer User Settings figure 2-3 Language selection: the user can select language between Chinese and English ; Select user: enter the corresponding password to enter the engineer mode. figure 2-4 engineer mode engineer mode:currently only support to adjust the damping of paper feeding.

-

Page 20: Print Monitoring

Model S High Speed Sublimation printer Figure 2-5 Main menu The interface includes the ‘print monitoring’, ‘main page’, ’purge printer’, ‘alarm’, ‘movement’, ‘platen suction’ menus. 2.2 Print monitoring Figure 2-6 Print monitoring (1)Pause “B” : If you find a nozzle plug or a problem with the material during printing, you can click this button and the machine will pause the printing. -

Page 21: Main Page

Model S High Speed Sublimation printer ( 2 ) Go on printing “A” : Click this button to continue the machine from the interruption. (3)Stop printing “C”: Click this button to cancel the printing and the machine to stop printing. -

Page 22: Purge Printer

Model S High Speed Sublimation printer figure 2-8 Main page 2.4 Purge printer Figure 2-9 Purge printer page... -

Page 23: Alarm

Model S High Speed Sublimation printer Name Description Caution The background color is the corresponding ink color: the auxiliary ink cartridge is full. Display sub ink tank status The background color is the corresponding ink color: the auxiliary ink cartridge is out of ink. -

Page 24: Movement

Model S High Speed Sublimation printer Shown as figure 2-10 that, Red is for alarm in going, orange is alarm acknowledged, yellow is alarm cleared. Clean Main Board Alarm:click it to relieve main board alarm. Figure 2-10 Alarm 2.6 Movement... - Page 25 Model S High Speed Sublimation printer 序号 名称 说明 注意事项 After clicking, the drop-down menu appears, which are low speed, medium speed and high The head carriage moves at speed. By selecting different different speeds in different parameters, the moving speed options.

-

Page 26: Platen Suction

Model S High Speed Sublimation printer After clicking this option, the nozzle holder will move to the right. Notes: in machine movement page, the printing is not able to proceed. It has to exit the interface then do printing job or test bar. -

Page 27: Rolling/Unrolling And Dryer Control

Model S High Speed Sublimation printer 2.8 Rolling/Unrolling and dryer control Interface for language switch Function: Manual start and stop control for rolling/unrolling control: default at OFF when machine power on, display "OFF" and it should be manually turned on, to "ON". - Page 28 Model S High Speed Sublimation printer The number at right side indicate the current dryer working temperature. Functions: Display real-time temperature of dryer and temperature setting. Set “Start” and “Stop” of dryer. Display Heating/Constant-Temperature/Alarm Status of Dryer. Setup: Set to “ON”, adjust the parameters of temperature and constant temperature. Set to “OFF”,...

-

Page 29: Chapter 3 Soft Panel Setting

Model S High Speed Sublimation printer Chapter 3 Soft panel setting 3.1 Soft panel interface 图 3-1 Serial Number Items Description Note Language switching, Chinese/English interface available Test bar printing Nozzle cleaning function: scraper, auto nozzle cleaning, manual ink pressure, nozzle flashing. -

Page 30: Software Setting And Machine Maintenance Tool

Model S High Speed Sublimation printer rinting parameters setting: Printing direction setting; Printing speed setting not available; The modification will Feathering setting; not take effect until Printing bar’s position setting; you click the button Test bar printing pass mode; of confirm. -

Page 31: Printing Accuracy Calibration Setting

Model S High Speed Sublimation printer Advanced setting: it is able to change ink channel order. Figure 3.3 Head setting:Head information, voltage, temperature and wave setting] Figure 3.4 3.3 Printing accuracy calibration setting Print heads verticality setting... - Page 32 Model S High Speed Sublimation printer Figure 3.5 Step calibration:figure regulation of paper step Figure 3.6 X direction calibration: unidirectional and bi-directional calibration for 508dpi and 300dpi...

- Page 33 Model S High Speed Sublimation printer Figure 3.7 Y direction calibration: accuracy compensation from the vertical direction of print heads Figure 3.8 Printing channel alignment: bi-directional printing accuracy calibration for 508dpi and 300dpi...

- Page 34 Model S High Speed Sublimation printer Figure 3.9...

-

Page 35: Chapter 4 Rip Software

Model S High Speed Sublimation printer Chapter 4 RIP software 4.1 RIP introduction Double-click to open the desktop AJet RIP x64 app, the following dialog box pops up: Figure 4-1 open RIP Left click on "File" in the menu bar to open "new work" to create a new blank job surface. As shown below:... -

Page 36: Printing Process

Model S High Speed Sublimation printer 4.2 Printing process Print job flow chart: ⅠStart a printing job 1. Zoom 2. Drag the picture 3. Picture-repeat Ⅱ Edit image 4. Picture cropping 1. ICC curve setting 2. Channel settings Ⅲ 3. Density curve call Print parameters settings 4. - Page 37 Model S High Speed Sublimation printer Edit image Move the mouse to the image and right click to bring up the edit menu. Figure 4-5 Editing the job ①Position: Left click to pop up the following dialog box to enter horizontal and vertical positions in horizontal and vertical.

- Page 38 Model S High Speed Sublimation printer ④ Copy: Select the image and click “Copy”, the image is juxtaposed with the position of the original image. Figure 4-8 Copy ⑤ Delete image: Select the image with the left mouse button and click “Delete Image” to delete the selected image.

- Page 39 AjetPrinter Printer Name: Used to select the model of the printer, default Model: Select the model of the current printer. This model is Model S. Attribute setting: set the current printing mode, print direction (one-way or two-way), dot size (large,...

- Page 40 Model S High Speed Sublimation printer Figure 4-13 Attribute Setting Channel Settings: Select the order of the ink tracks and save them. (The order of this ink path should be the same as the order of outputting the pure ink color card). You can click the “Print Test Strip” button to print the color of each channel, and then input it in turn.

- Page 41 Model S High Speed Sublimation printer Color Control: Mainly used to control the color and density of printing, color management. A:Density curve: The purpose is to control the amount of ink produced by each ink to linearize the level of each ink.

- Page 42 Model S High Speed Sublimation printer ② When there is an ICC curve (for example, in North American standards), use the embedded ICC file to check, RGB in the input select Adobe RGB (1998), CMYK select Japan Color 2001 Coated; printer ICC profile selects the ICC curve of the corresponding density curve ( The ICC curve is produced by the engineer).

-

Page 43: Pause/Cancel A Printing Operation

Model S High Speed Sublimation printer Printing Figure 4-19 Print image Figure 4-20 Copy number Set the number of copies (that is, the number of copies of the print job), then click "OK" to start outputting a job and start printing. - Page 44 Model S High Speed Sublimation printer Figure 4-22 Figure Note: Stopping a print job as an interrupted print job cannot be continued. (3) : Stop printing can be controlled through the touch screen When you need to cancel/end the print job, you can use the keyboard shortcut “ESC” to pop up the following interface.

- Page 45 Model S High Speed Sublimation printer Figure 4-24 Touch screen to stop print...

-

Page 46: Chapter 5 Basic Operation

Model S High Speed Sublimation printer Chapter 5 Basic operation 5.1 Preparation before starting up 5.1.1 Environmental requirements The temperature is controlled between 20 C and 30 C, and the humidity is controlled at 55% to 70% RH.55%~70%RH. 5.1.2 Site requirementsh The workplace must be clean and free of dust, smoking and fireworks are strictly prohibited;... -

Page 47: Machine Check After Start Up

Model S High Speed Sublimation printer Figure 5-1 Switch button Note: The nozzle holder will automatically return to the cleaning position after pressing the power button. Do not touch the moving nozzle holder and suction platform. 5.2.2 Machine check after start up (1) Wiper: Check whether the blade and the base are clean, remove the accumulated ink on the surface and dry dirt;... -

Page 48: Test Bar Printing

Model S High Speed Sublimation printer Figure 5-3 (2) Click the “head cleaning” option in the function interface , and enter the head cleaning interface as shown in Figure 3-3 . Click automatic cleaning in the page Figure 5-4 (3)Open Ajet Server, do test bar printing. -

Page 49: Paper Feeding

Model S High Speed Sublimation printer When the display shows the desktop, double-click the Server icon on the desktop to open the Server software. FIgure 5-6 Open Server Set the scan direction value (in mm) and click the “Print Test bar” option... -

Page 50: Paper Loading

Model S High Speed Sublimation printer Print side Figure 5-8 Printed surface of the material 5.3.2 Paper loading Figure 5-9 Paper roller loading (1) Insert the printing paper into the unwinding lever (air expansion roller) and pump it to fix the paper. -

Page 51: Machine Shutdown

Model S High Speed Sublimation printer Note: Place the air-expansion roller in the bracket so that both ends are placed at the same time. When removing the inflation roller from the holder, remove both ends at the same time. (2)... -

Page 52: Chapter 6 Daily Maintenance

Model S High Speed Sublimation printer Chapter 6 Daily Maintenance 6.1 Examination before printing (1) Checking the status of the nozzle before printing: the self-checking strip of the printing nozzle is automatically or manually cleaned, dripping ink, etc., so that the nozzle is in a normal state. -

Page 53: Weekly Maintenance

Model S High Speed Sublimation printer 6.3 Weekly maintenance (1) Clean the machine and dry the ink and dust on all parts (including beams, drying platen fans, computers, etc.). (2) Check the gas path and ink path: Check whether the pipe joints are loose or not, whether the pipes are creased or not. - Page 54 Model S High Speed Sublimation printer (1)Within 3 days break Make sure that the head is in good condition and shut down normally according to the operating specifications. (2)3-10 days break The nozzle is first cleaned with deionized ions, cleaned and replaced with cleaning solution, and the customer can be arranged to be on duty according to the operating specifications.

-

Page 55: Chapter 7 Eliminate Of Frequent Malfunction

Model S High Speed Sublimation printer Chapter 7 Eliminate of frequent malfunction 7.1 Machine malfunction code and treatment EC_CARRIER_STALL Print head carrier resistance Unnormal grating signal, motor or motor is large signal EC_CARRIER_REVERSE_DIR Print head carrier reverse Grating B phase opposite, motor direction... - Page 56 Model S High Speed Sublimation printer EC_FIBER_ERR Fiber optic can't optical fiber wiring unnormal communicate EC_EMPTY_PAPER Empty paper alarm paper used up EC_PAPATABLE_ID_ERR The parameter table ID does Parametric unnormal error not match the registration ID EC_PAPA_INIT_ERR Invalid parameter table...

-

Page 57: Print Head Bad Condition, Phenomenon And Solution

Model S High Speed Sublimation printer 7.2 Print head bad condition, phenomenon and solution Description Cause Solution 1. Cleaning, purge to wash out the air bubble. Few nozzles not 2. Lower the negative pressure, dropping for a jetting, but not moment, in order to remove the air bubbles.

Need help?

Do you have a question about the S and is the answer not in the manual?

Questions and answers