Table of Contents

Advertisement

Quick Links

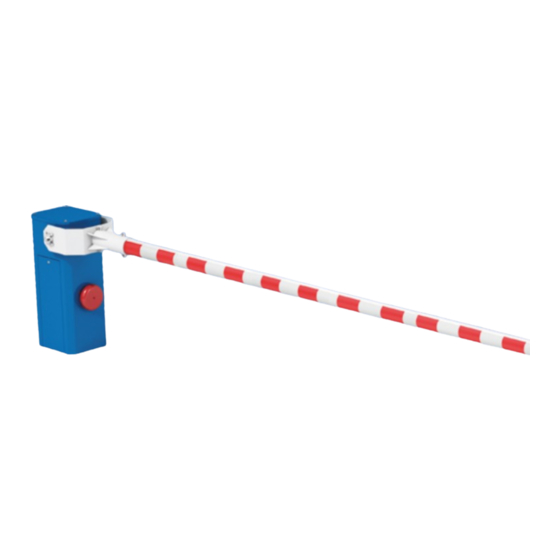

THE VEHICLE AND PEDESTRIAN ACCESS CONTROL SPECIALIST

OPERATING INSTRUCTIONS

LIFTING BARRIERS

LBA 12 IRREVERSIBLE

Before installing or repairing your equipment, we recommend that you read these user and operating

instructions carefully.

We are at your disposal for any additional information or comments.

Please contact our After-Sales Service on +33 (0)4 78 86 02 86, from Monday to Friday, 9 am to 6 pm.

451 Chemin de Champivost - 69760 LIMONEST

Tél : +33 (0)4 78 86 02 86

www.grouplba.com - contact@lbagroup.fr

Advertisement

Table of Contents

Summary of Contents for LBA GROUP LBA 12 IRREVERSIBLE

- Page 1 THE VEHICLE AND PEDESTRIAN ACCESS CONTROL SPECIALIST OPERATING INSTRUCTIONS LIFTING BARRIERS LBA 12 IRREVERSIBLE Before installing or repairing your equipment, we recommend that you read these user and operating instructions carefully. We are at your disposal for any additional information or comments.

-

Page 2: Table Of Contents

Installation and maintenance manual lba12 Table of contents INTRODUCTION : ..........................4 : ................................ 4 AFETY ..............................5 ARNING ..............................5 NFORMATION CONDITIONS OF USE .......................... 6 ........................... 6 NVIRONMENTAL CONDITIONS ............................6 LECTRICITY SUPPLY ......................... 6 OMPLIANCE WITH STANDARDS .............................. - Page 3 Installation and maintenance manual lba12 6.6.2 Description ............................26 6.6.3 LED indicators : ..........................26 6.6.4 Local controls: ..........................27 6.6.5 Protections: ............................. 27 6.6.6 Connection of the electronic board ....................27 6.6.7 Programming ..........................28 MAINTENANCE: ..........................37 ............................37 ANUAL OPENING : ........................

-

Page 4: Introduction

Installation and maintenance manual lba12 1 Introduction : 1.1 Safety : Thank you for choosing La Barrière Automatique to secure and regulate access to your site(s). You can be sure that you will be satisfied with your purchase for many years to come. -

Page 5: Warning

Installation and maintenance manual lba12 1.2 Warning Your barrier comprises a mechanism and various electrical components. Any negligence during repair or maintenance can have serious consequences for your safety or for that of other people. The fixed support plate is equipped with a crank position microswitch, which prevents any movement of the mechanism when there is no contact. -

Page 6: Conditions Of Use

Installation and maintenance manual lba12 2 CONDITIONS OF USE 2.1 Environmental conditions • Operating temperature: –30 °C to +55 °C • Maximum humidity level: 95% between –25 °C and +40 °C, 50% above 30 °C • Presence of water: code AD5 (washing with water jet from all directions; notes that high-pressure washing is possible if the jet is kept at least one metre away) •... -

Page 7: Nameplate

Installation and maintenance manual lba12 NF EN 60034-1: Rotating electrical machines 2.4 Nameplate Each barrier is supplied with a nameplate that indicates the type of barrier, the serial number and the date of assembly:... -

Page 8: Technical Description Of The Barrier

Installation and maintenance manual lba12 3 TECHNICAL DESCRIPTION OF THE BARRIER 3.1 DESIGN PRINCIPLES The barriers presented in this document have been designed to meet difficult operating requirements with a high number and frequency of cycles. Maintenance has been facilitated by the use of modular subassemblies, which enable repair times to be very short. -

Page 9: Installation Plan For Lba 12

Installation and maintenance manual lba12 3.4 Installation plan for LBA 12 3.4.1 Configuration “normal” Crank Door 3.4.2 Configuration “reverse” Crank Door... -

Page 10: Dimensions

Installation and maintenance manual lba12 3.4.3 Dimensions LBA12 with support Arm lenght (mm) 3000 4000 5000 6000 7000 8000 9000 10 000 11 000 12 000 Passage width (mm) 3000 4000 5000 6000 7000 8000 9000 10 000 11 000 12 000 Distance between 3000... -

Page 11: Construction

Installation and maintenance manual lba12 4 Construction: Construction of a 1000×1000×1000mm concrete foundation for the barrier casing following the recommendations below. These must be properly constructed for the barrier to be correctly installed. Foundations must be perfectly horizontal and be at least at the level of the top surface finished floor. -

Page 12: Access To The Interior Of The Barrier

Installation and maintenance manual lba12 5.1 Access to the interior of the barrier 5.1.1 Opening the door To open the door, it is necessary to have a TYPE 405 key (or other on request). 5.1.2 Opening the cover The cover is removed by unscrewing the 4 screws located on each corner of the cover (See arrow on following figure). -

Page 13: Posing The Barrier

Installation and maintenance manual lba12 5.2 Posing the barrier: 5.2.1 On a standard plate: After finishing construction, the barrier can be installed following the procedure below: 4 COUNTER NUTS M20 4 NUTS M20 4 FLAT WASHERS M20x60 PVC plate 4 ANCHOR RODS 20x400mm SLEEVE Control+Power C - Nuts M20 + washers... -

Page 14: On A Rotation Plate

Installation and maintenance manual lba12 5.3 Electrical and control connection The supply voltage for the barrier is 230 V ± 10%, 50 Hz ± 2 Hz monitor phase according to NFC 15-100. Power cuts lasting less than 100 ms will not affect operation. The barrier must be supplied by a 3G 1.5mm²... -

Page 15: Principle Of Operation ( Basic )

Installation and maintenance manual lba12 5.4.2 Assembly of support (option) Construction of a 400×400×600 concrete foundation for the barrier support following the recommendations below. These must be properly constructed for the barrier to be correctly installed. The sleeving necessary to pass the cabling for electrical supply, barrier control, safety, etc. - Page 16 Installation and maintenance manual lba12 5.4.3 Cam setting The barrier is equipped with 2 mechanical sensors coming into contact with cams. These limit switches and cams are accessible after removing the cover. The limit switch closest to the gear unit is that of the opening. Then there is the safety sensor (not shown in the images below) and then the closing sensor).

-

Page 17: Presentation

Installation and maintenance manual lba12 ► Presentation on the interface o General interface Relay Power Digital inputs (x8) Modbus RTU Encoder Brake 230Vac Card Analogue (or digital) inputs (x4) Transistor outputs 24Vdc (x6) Ethernet User interface Analogue Dry contact relay outputs (x6) RJ45 Three-phase Output... -

Page 18: Assembly Of The Hanging Stand (Option)

Installation and maintenance manual lba12 o Inputs/outputs ▪ Inputs/outputs description Inputs/outputs Terminal Terminals Description block(s) Digital inputs 24Vdc I1 to I8 - ; + ; Ix 24Vdc All or Nothing inputs for the barrier controls Digital inputs 0-10V (or digital 24Vdc) AI1 to AI4 - ;... -

Page 19: Electromagnetic Pad For Support (Option)

Installation and maintenance manual lba12 Flashing light on cover Lights on arm Suction cup/locking Unhinging alarm Green light Red light Relay outputs Description Open barrier report (NO) Closed barrier report (NO) Barrier unhinged/fallen arm report (NC) Safety loop report (NO) Fault summary report (NC) Not assigned Note: These are the default input/output assignments. -

Page 20: Adjustment

Installation and maintenance manual lba12 • Information" screen (default screen): This display is the default screen, it indicates useful information for the installer: ====Informations==== Frequency of the motor (in Hz): this corresponds to the frequency of the current injected Fr: -7 Hz into the motor. -

Page 21: Adjustment Of The Overrun Security Sensor

Installation and maintenance manual lba12 Note: The screen display automatically returns to the "Information" screen after 60s if no button is pressed. Details on the main menu will be provided hereinafter. ▪ LEDs: The LEDs also make it possible to view the status of the inputs/outputs as well as the useful voltages: •... -

Page 22: Adjustment Of The Frequency Variator

Installation and maintenance manual lba12 ► Main menu: To go to the main menu, press the "ESC" and "ENTER" keys simultaneously for 3s. o Choice of the user: Before accessing the main menu, you must first select the user. You can choose between two users: "OP" and "ADMIN": ====USER SELECT==== ADMIN Contrary to the access to the menu via the "OP"... -

Page 23: Modes Du Variateur

Installation and maintenance manual lba12 Once the user is selected and, where applicable, the password has been entered, you will access the PLC's main menu, the "PLC MENU" screen is displayed: ==== PLC MENU ===== INFORMATIONS STOP PLC USER PARAMETERS o "INFORMATION"... -

Page 24: Loading Or Copying A Drive Program From A Sd Card

Installation and maintenance manual lba12 o "USER PARAMETERS" - Settings for the program: The "USER PARAMETERS" functions provides access to the list of user settings that can be modified in order to adjust the barrier. Some of these settings can be accessed only via the "ADMIN" user. Here is the list of default settings: Setting Description... - Page 25 Installation and maintenance manual lba12 ● Reversibilite Option to be activated when the barrier is reversible in order to activate the "holding torque" function (TRUE: activated; FALSE: deactivated) ● Reouverture_secu Activation of the automatic reopening on detection of a safety component (loops, IR cell, ultrasound, etc.) (TRUE: activated;...

-

Page 26: Adjustment Of The Enpc001652 Control Board

Installation and maintenance manual lba12 o "DOWNLOAD PLC PROG" - Modification of the program using an SD card: To modify the program of the barrier using an SD card, you must: Remove the SD card already present and insert the SD card which contains the program into the housing provided at the top left of the board Go to the menu of the control board by pressing the "ESC"... -

Page 27: Local Controls

Installation and maintenance manual lba12 o "UPLOAD PLC PROG" - Recording of the program on an SD card: To modify the program of the barrier on an SD card, you must Remove the SD card already present and insert the SD card into the housing provided at the top left of the board Go to the menu of the control board by pressing the "ESC"... -

Page 28: Programming

Installation and maintenance manual lba12 o "LOCATED VARS" - Local variables of the program: The "LOCATED VARS" tab provides access to the statuses of the local variables of the barrier for the purposes of troubleshooting, for example. This function can be accessed only with the ADMIN profile (See §4.1. Choice of the user) Here is the list of available variables: Variable Description... - Page 29 Installation and maintenance manual lba12 ► TCP/IP Modbus Communication: The ONE-C control board can be controlled via the Ethernet port or the RS485 port using the Modbus communications protocol. o RS485 Communication: The control board is configured as a slave. If the control board is not located at the end of the line, remove the jumper located to the right of the connector.

- Page 30 Installation and maintenance manual lba12 o Exchange table: The Modbus exchange table for the board is as follows: Data Data type Direction Type Address Description Controls Boolean Read Coil Open command (0 = non-active; 1 = active) Boolean Read Coil Close command (0 = non-active;...

- Page 31 Installation and maintenance manual lba12 ► Web server The ONE-C control board has a built-in web server that makes it possible to view, control, and configure the barrier using a web browser. o Connection to the barrier To connect to the barrier, simply connect the barrier to the network using an Ethernet cable via the RJ45 port located to the lower right of the control board.

- Page 32 Installation and maintenance manual lba12 When you open the web server in your browser, you will see the home page below. The web server has three possible levels of authentication, with each one offering different possibilities for supervision: • No identification: Viewing of the status of the barrier •...

- Page 33 Installation and maintenance manual lba12 o Home page The web server's home page provides a precise view of the status of the barrier as well as the possibility to control the barrier for the "OP" and "ADMIN" profiles. Below is an example of the home page for an "OP" profile. In this example, the barrier is closed and is in fault.

- Page 34 Installation and maintenance manual lba12 None Red light: The barrier is not open or is about to close. Passage is prohibited. The "Red light" output is activated. None Green light: The barrier is open and is not about to close. Passage is authorised.

- Page 35 Installation and maintenance manual lba12 o Other tabs ▪ "Configuration" tab The "Configuration" tab makes it possible to configure the barrier's network settings. This allows you to choose whether you want the barrier to have a fixed (Static) IP address or if you want the IP address to be assigned automatically by the network that the barrier is connected to (DHCP).

- Page 36 Installation and maintenance manual lba12 Note: The page has to be refreshed in order to view the new status of the variables. ▪ Informations" tab The "Informations" tab includes the list of advanced information for the barrier's program and control board (see §3.2. "INFORMATIONS"...

-

Page 37: Maintenance

Installation and maintenance manual lba12 6 maintenance: It is imperative to disconnect the power supply before performing maintenance or maintenance on the barrier. 6.1 Manual opening 1- Open door of the barrier using the key (basic key 405) 2- Take the crank fixed to the edge of the plate The crank is located over a circuit breaker enabling the supply to the electronic card to be cut off (user protection). -

Page 38: Preventative Maintenance

Installation and maintenance manual lba12 Preventative maintenance: We advise you to carry out at least one preventative check each year. For intensively used barriers, a cheque every six months would be more appropriate. Checks to be carried out: • External cleaning, verification of the absence of impacts, scratches, etc. that would favour the appearance of corrosion •... -

Page 39: Corrective Maintenance

Installation and maintenance manual lba12 6.2 Corrective maintenance: 6.2.1 Replacement of the compensation system The replacement of the compensation system is carried out with the power off by the following procedure: A- Remove the open stop B- Manually position the rail at more than 90° to completely remove spring tension C- Remove the cover fixing screw D- Remove the clip with rat nose pliers E - Before completely removing the clip, attach the chain with a cord to then lower the... -

Page 40: Replacement Of The Spring

Installation and maintenance manual lba12 F - Lower the compensation assembly to the bottom of the barrier casing and remove the spring with the cover 6.2.2 Replacement of the spring... - Page 41 Installation and maintenance manual lba12 Pull on the tension rod to remove the chain + rod assembly The spring is found in the cover 6.2.3 Tension Spring setting 1- After taking out the compensation package 2- On the pulling unscrew with 2 keys of 30 against the nut 3- Screw or unscrew the 2nd nut to adjust the tension of the spring 2cm max.

- Page 42 Installation and maintenance manual lba12 A - Tie-chain + spring rest in the bell B- Refit the bell inside the housing and reassemble the chain through the hole provided and attach the chain to the pinion C- Refit the quick coupler and center the chain D- Using the crank and the brake release lever, position the beam horizontally so that it closes the way E- Reposition the opening stop...

-

Page 43: Replacement Of The Motoreducer Group

Installation and maintenance manual lba12 6.2.5 Replacement of the motoreducer group The replacement of the motoreducer group is done following this procedure: 1- Cut off the electrical supply 2- Remove the arm and the half-shells 3- Remove the compensation system 4- Using a hub puller, remove the flange on the sprocket side (force fitting on tapered and keyed shaft to clear the clearance) 5- Loosen the point screw on the eccentric ring of the bearings... - Page 44 Installation and maintenance manual lba12 12- Unclip the brake motor (Brake connect to the upper terminal block and the motor wired to the frequency converter) 13- Uncouple the gear unit motor 14- Remove the 4 screws holding the secondary gear on the top plate 15- To uncouple the 2 gear units, remove the 4 screws holding the primary reducer on the connecting bell...

- Page 45 Installation and maintenance manual lba12 7 Electrical diagrams:...

- Page 46 LA BARRIERE AUTOMATIQUE 451 Chemin de Champivost 69760 LIMONEST FRANCE Tél : +33 (0)4 78 86 02 86 E-mail : contact@lbagroup.fr Internet : www.grouplba.com...

Need help?

Do you have a question about the LBA 12 IRREVERSIBLE and is the answer not in the manual?

Questions and answers