Summary of Contents for KSB ITUR IPR Series

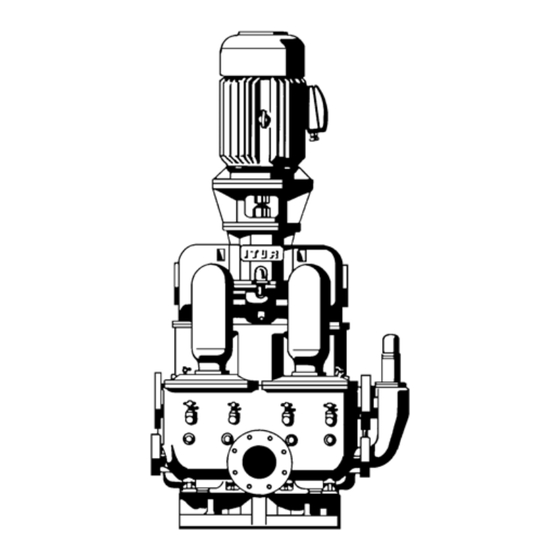

- Page 1 IPR, IPRT Alternating Piston Pumps Jansen Pompentechniek T: +31(0)485-371318 E: info@pompentechniek.nl...

-

Page 2: Table Of Contents

IPR, IPRT Index 7 MAINTENANCE/CONSERVATION......8 1 GENERAL ITEMS ............3 7.1 G ........... 8 ENERAL INSTRUCTIONS 7.2 M ........8 AINTENANCE INSPECTION 2 SAFETY ..............3 7.2.1 Checking instructions ........8 2.1 S ....3 IGNALLING OF WARNINGS IN THIS MANUAL 7.2.2 Lubrication ............ -

Page 3: General Items

Should you require further details or have a breakdown Danger to the environment due to escaping noxious problem, please contact the nearest KSB ITUR service agent. products. Conscientious safety at work Safety The safety instructions contained in this Manual must be... -

Page 4: Safety Instructions For Maintenance

Type of stroke shown on the delivery note or on the factory plate; if it is not, and the equipment cannot be handled safely, please contact KSB ITUR. Form of construction Remember that the equipment must never be lifted using the Constructed with a vertical attachment base and electrical ring bolts of the different items (e.g. -

Page 5: Installation

KSB ITUR only offers details and comments as the type of installation. a help, but does not assume any responsibility with regards to the design, assembly and operation of any installation. -

Page 6: Motor Connection

IPR, IPRT 5.4.1 Motor connection Start-up Whilst connecting the cables, ensure it is not possible Start-up shall be carried out when all the necessary for voltage to appear. mechanical, hydraulic, electrical and pneumatic connections are complete. Check that the earth connection is in line with local The safety bypass valve should be regulated before starting regulations. -

Page 7: Final Control

IPR, IPRT If the regulation of the valve is unduly altered, there is Shaft sealing a danger of excess pressure (breakage of pipes Packing: The gland nuts must be gently tightened (by hand). and/or pumps) and/or destruction of the motor The gland must form a right angle to the shaft. -

Page 8: Starting Up After Storage

IPR, IPRT 7.2.2 Lubrication Starting up after storage If the storage and/or shutting down of the pump has been for Before lubricating the pump, ensure that: a prolonged period of time (over 6 months), it is necessary to: The pump is shutdown and cannot be started up Check the state of the joints. -

Page 9: Mptying Rainage

IPR, IPRT 7.4.5 Segments and pump casing Emptying/Drainage Separate the cross guide support and the reducer box of The emptying and drainage of pumps used to expel the valve box. liquids which are a health hazard must be carried out in such a way as there is no risk to people or to the Release the male and female couplings, unscrewing the environment, in line with legislation. -

Page 10: Packing

IPR, IPRT 7.5.2 Packing 7.5.4 Segments and pump casing Cut the new packing, forming as many rings as required. Introduce the casing with the help of a plastic hammer. The cuts, seen from above, may be straight or inclined at The segments shall be positioned with their cuts 45º. -

Page 11: Recommended Spare Parts

IPR, IPRT Recommended spare parts Recommended spare parts (1) Piece denomination Reference No. (2) Start-up 2 years 5 years Flanges (set) Packing Valve spring (set) Segments (set) Bearing (set) Lip seal (set) Lantern ring (set) Shaft bushing (set) Shaft casing (set) Bearing bush (set) Flexible coupling part (set) Safety ring (set) -

Page 12: Operation Anomalies

IPR, IPRT Operation anomalies Bang inside the drive reducer | The pump works "heavily", the valves bang | | Metal bang on the side part of the pump | | | Cause Solution Tighten the safety screw within the cross piece The cross bolt has become loose and secure again Remove the adjustment sheets, and, if necessary,... -

Page 13: Annexes

IPR, IPRT Annexes Sectional plans Sectional C-606, IPR-100 Jansen Pompentechniek T: +31(0)485-371318 E: info@pompentechniek.nl... - Page 14 IPR, IPRT Ref. Denomination Ref. Denomination Ref. Denomination 0 Reducer box 51 Safety ring 101 Flat washer 1 Reducer box cover 52 Allen screw 102 Flat washer 2 Lip seal cover (crown) 53 Lip seal 103 Stud 3 Cover 54 Bearing 104 Nut 4 Cross guide support 55 Stud...

- Page 15 IPR, IPRT Sectional C-607 IPR 125/150 Jansen Pompentechniek T: +31(0)485-371318 E: info@pompentechniek.nl...

- Page 16 IPR, IPRT Ref. Denomination Ref. Denomination 1 Motor lantern 63 Rod base 5 M16x55 stud attachment reducer-lantern 64 Lower rod bushing 6 M16 nut 65 Pin bush bearing 7 Flat washer with bevel for M16 66 Adjustment screw 8 Female sleeve 67 M12 nut for adjustment screw 9 Male sleeve 68 Pipe of Ø4x240...

- Page 17 IPR, IPRT Ref. Denomination Ref. Denomination 126 Hatch cover of support 182 Discharge valve flange 127 Flange for hatch cover and safety valve 183 Discharge valve 128 M16x55 studs for hatch cover 184 Discharge valve spring 129 M16 nut for hatch cover 185 Discharge valve guide screw 131 Plug 1/2"...

- Page 18 IPR, IPRT Sectional C-1083 IPRT Ref. Denomination Ref. Denomination Ref. Denomination 1 Cock P029 Rear bushing P527 Plug 04.1 Pressure screw P031 Pressure ring P534 Packing cover 04.2 Pressure screw P032 Bushing P540 Valve box 30 Grease nipple P035 Flange P547 Valve box cover 37 Air renewal cock P040 Disc...

- Page 19 This warranty will be reduced to 6 months for continuous or permanent service pumps. KSB ITUR Spain, S.A. shall not be liable for any direct or indirect damage which the product suffers as a result of defective installation, lack of maintenance, negligent handling, handling by unauthorised personnel, overloading or deficient functions.

Need help?

Do you have a question about the IPR Series and is the answer not in the manual?

Questions and answers