Summary of Contents for LORCH MF-07

- Page 1 LORCH Schweißtechnik GmbH PO Box 1160 D-71547 Auenwald Tel: +49 (0) 7191 / 503-0 Fax: +49 (0) 7191 / 503-199 Website: www.lorch.biz email: info@lorch.biz Operation Manual Wire feeder MF-07 (EU) 909.1930.1-01...

- Page 2 This documentation including all its parts is protected by copyright. Any use or modification outside the strict limits of the copyright law without the permission of LORCH Schweißtechnik GmbH is prohibited and liable to prosecution. This particularly applies to reproductions, translations, microfilming and storage and processing in electronic systems.

-

Page 3: Table Of Contents

Table of contents Machine elements ....4 Explanation of symbols ..5 Meaning of the symbols in the operation manual . . -

Page 4: Machine Elements

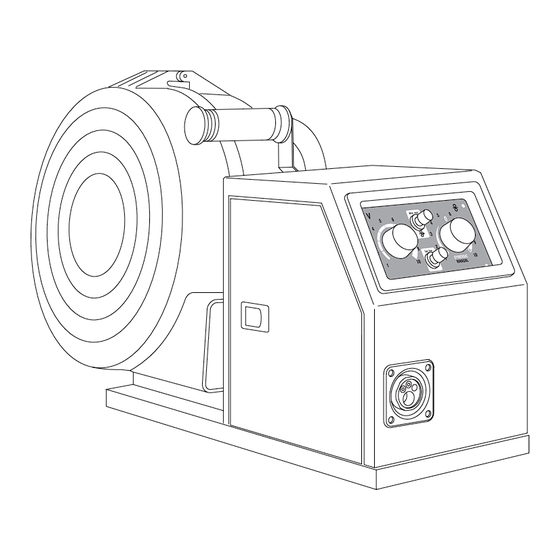

Machine elements Machine elements 10 11 12 Protective cover wire coil Central socket Handle (hoisting point) Torch holder Wire coil guiding spike Inert gas connection Side panel Control cable connection Closure Welding current connection Feed unit Interpass hose package Wire feed button - 4 - 06.13... -

Page 5: Explanation Of Symbols

Explanation of symbols Explanation of symbols Meaning of the symbols in the opera- Meaning of the symbols on the tion manual machine Danger to life and limb! Danger! If the danger warnings are disregarded, Read the user information in the operation this can cause slight or severe injuries or manual. -

Page 6: Safety Precautions

Safety precautions Safety precautions Hazard-free working with the machine is The machine must be transported or set only possible if you read the operating and up only on firm, level surfaces. safety instructions completely and strictly The maximum admissible angle of inclina- observe them. -

Page 7: Ambient Conditions

EN 60974-4. Please use the machine in compliance with the manu- Lorch recommends inspections at 12 month intervals. facturer's instructions. The operator of the equipment is A safety inspection must also be carried out if modifica- responsible for the installation and use of the machine. -

Page 8: Transport

Transport Transport Danger of injury due to the device fall- ing. For transport using mechanical lifting equipment (e.g. crane, ...) only handle 2 may be used as the hoisting point. Use suitable load-bearing equipment. Do not use a fork-lift truck or similar de- vice to lift the machine by its housing. -

Page 9: Before Start-Up

Push the connections of the interpass hose package source with internal controller for MIG 13 of the welding power source through the opening welding is required (e.g. Lorch MX 350 of the wire runoff plate. (EU)).  Fasten the interpass hose package 13 on the wire runoff Please observe the operating manual of plate by turning the hexagon. -

Page 10: Insert The Welding Wire Spool

Before start-up 10.2 Insert the welding wire spool 10.3 Thread the wire electrode in Injury and fire hazard through glowing Risk of injury due to crushing when reach- welding seams or parts! ing into the wire feed rollers or feed unit gears. -

Page 11: Connecting The Inert Gas Cylinder

Before start-up 10.4 Connecting the inert gas cylinder  Thread the wire electrode through the inlet nozzle 26 and the central socket 8.  Fold the swivel arm 25 down and secure in position with the tilt levers 24.  Switch on the welding power source at the main switch. -

Page 12: Start-Up

Start-up When using a feed case, a welding power Please observe the operating manual of source with internal controller for MIG the welding power source! welding is required (e.g. Lorch MX 350 (EU)). Fig. 7: Control panel Wire feed button Â... -

Page 13: Repair And Maintenance

In this case the manufacturer's warranty is no longer valid and the manufacturer accepts no product liability for the equip- ment. If you experience problems or need re- pairs, contact a dealer authorised by Lorch. 06.13 - 13 -... -

Page 14: Troubleshooting

Troubleshooting Troubleshooting Fault Possible cause Rectification Torch becomes too hot The torch is clogged by dirt in the cool- Flush the torch with water hoses out in ant system the opposite flow direction Contact tip not tightened properly check Torch switch has no function when Union nut from torch hose pack to cen- Tighten the union nut actuated... - Page 15 Troubleshooting Fault Possible cause Rectification Inert gas feed insufficient Inert gas quantity set incorrectly at the Set the inert gas quantity as described pressure reducer in the operating instructions Pressure reducer dirty Check the pressure reducing nozzle Torch or gas hose blocked or leaking Check and replace if necessary Inert gas blown away by draughts Eliminate the draughts...

-

Page 16: Technical Data

Declaration of conformity Technical data Service Lorch Schweißtechnik GmbH Case PO Box 1160 Machine type MF-07 D-71547 Auenwald, Germany Welding Tel. +49 (0)7191 503-0 Welding range (l 2max) +49 (0)7191 503-199 Welding current at ED 100 % 40°C A Welding current at ED 60 % 40°C... - Page 17 Declaration of conformity 06.13 - 17 -...

-

Page 18: Ersatzteilliste / Spare Parts List / Список Деталей

Ersatzteilliste / spare parts list / Список деталей Ersatzteilliste / spare parts list / Список деталей Ersatzteilliste / spare parts list / Список деталей 990.4473.7-00 Vorschubkoffer MF-07 (EU) wire feeder MF-07 (EU) Блок подачи проволоки MF-07 (EU) 2...5 2...5 2...3 4...5 Mat.Nr. -

Page 19: Stromlaufplan / Schematic / Схематический

Stromlaufplan / schematic / Схематический Motor Solenoid valve Torch Inching 10K/2W 4,7K/2W Wirespeed RV24YN20S/15A502 IN 4007 Voltage RV24YN20S/B502 IN 4007 Gas test Stromlaufplan / shematic-diagram erstellt am/von Koffer MF-07 (EURO) 16.05.2012 F. Becker provided to/of S00.0069.7-00 geändert am/von changed to/of 06.13 - 19 -... - Page 20 Lorch Schweißtechnik GmbH Im Anwänder 24 - 26 D-71549 Auenwald Germany Tel.: +49 (0)7191 503-0 Fax: +49 (0)7191 503-199 info@lorch.biz www.lorch.biz...

Need help?

Do you have a question about the MF-07 and is the answer not in the manual?

Questions and answers