Summary of Contents for Clemens Technologies HEXAGON 723

- Page 1 User’s manual HEXAGON Compact cultivator Item number: CL723.000000, CL724.000000, CL729.000000 Manufacturer: Maschinenfabrik CLEMENS GmbH & Co.KG Rudolf - Diesel - Straße 8 D-54516 Wittlich / Germany HEXAGON 07.2019 en...

-

Page 2: Table Of Contents

Basic frame with sliding units and hydraulic width adjustment (all models) ....14 Master and slave cylinder for HEXAGON 729 ..............16 Master and slave cylinder for HEXAGON 723 ..............17 Master and slave cylinder for HEXAGON 724 ..............18 Extensions, guard rails, lower link extension .............. -

Page 3: Preface

1 Preface Dear Customer! With the HEXAGON cultivator you have acquired an extremely stable cultivator whose width is hydraulically adjustable. This ensures optimum adaptation to almost every row width. Further equipment features offered for the CLEMENS HEXAGON are the possibility of attaching a land roller and mounting a CLEMENS RADIUS weeder on both sides with or without lateral angle correction (mechanical or hydraulic). -

Page 4: Ec Declaration Of Conformity

2 EC Declaration of Conformity in line with the EC Directive 2006/42/EEC Manufacturer / Address: CLEMENS GmbH & Co. KG/Maschinenfabrik Rudolf-Diesel-Straße 8 D-54516 Wittlich/Germany We herewith declare that the design of: Machine type: Cultivator HEXAGON with hydraulic width adjustment complies with the following relevant provisions (directives: Machinery directive 2006/42/EC The following (harmonized) standards have been applied:... -

Page 5: Machine Description: Hexagon Cultivator

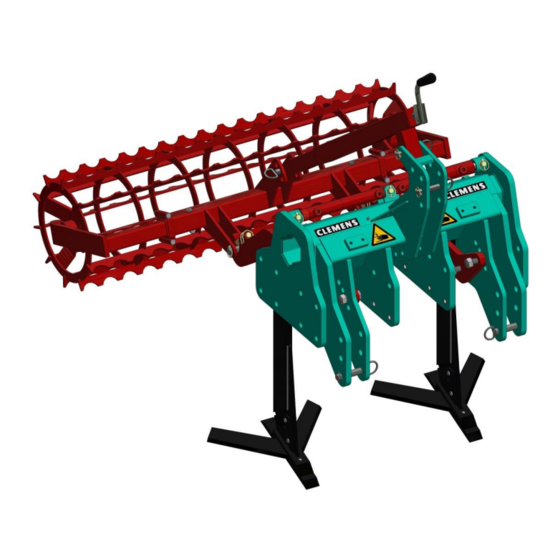

3 Machine description: HEXAGON cultivator The CLEMENS HEXAGON mainly consists of the following components: Width adjustment with master/slave cylinder Land roller Two sliding units Tools e.g. chisel bodies Basic frame Figure 1 Overall view The working principle of the CLEMENS HEXAGON is that the working width of the basic frame is infinitely adjustable with the aid of a master/slave cylinder and can thus be adapted to suit the individual row widths. -

Page 6: Commissioning And Working With The Hexagon

4 Commissioning and working with the HEXAGON 4.1 Before initial commissioning Carefully study the operating manual of the HEXAGON and the additional devices and familiarise yourself with the operation of the equipment. Check to see whether the hydraulic connections fit to your tractor. Check whether all screws on the HEXAGON are fastened well. - Page 7 (3) Clamping sleeves which serve to accommodate M16 screws (shearing screw and attachment screws of the clamps) are located in the bottom series of holes. If attachment clamps are used, clamping sleeves must also be inserted in the top holes. It must be ensured that the slit in the clamping sleeve always points upwards. If you work with Bison tines, always mount them on the base frame, never on the sliding parts! In order to be also able to work broad rows, extensions with hexagon profile, like the basic frame, can be attached.

-

Page 8: Mounting Option C.drive

4.4 Mounting option C.DRIVE In order to make optimum use of the advantages of the CLEMENS C.DRIVE controller on the HEXAGON cultivators, parts of the hardware provided for this purpose must be mounted on the respective cultivator frame, depending on the equipment. The 2 variants of the bracket shown are intended for this purpose. -

Page 9: Application Of The Brackets To The Hexagon Cultivator

4.4.2 Application of the brackets to the HEXAGON cultivator 1. Support small for HEXAGON (CL846.402000) Flow divider Relay box Cable set Control unit block 4DA Figure 7 Mounting with support small 2. Support large for HEXAGON (CL846.404000) Relay box Cable set Hydraulic block 5 Figure 8 Mounting with support large HEXAGON 07.2019 en... -

Page 10: Maintenance And Care

5 Maintenance and care The CLEMENS HEXAGON is designed so that it requires a minimum of maintenance and care. However, the following points should be observed: After the first 2 hours of operation, all screws are to be checked for a tight fit, afterwards check them before every day of operation. -

Page 11: Notes On Safety

6 Notes on safety The HEXAGON may only be operated when all the protective facilities and safety-related devices are installed and operable. Faults which may reduce the machine safety are to be rectified without delay by qualified staff. Do not change any hydraulic connections. This can lead to malfunctions and thus jeopardize people’s safety. The operating manuals of any additional attachments are to be studied and observed carefully. -

Page 12: Technical Data: Hexagon Cultivator

7 Technical data: HEXAGON cultivator CL723.000000 CL729.000000 CL724.000000 Dimensions approx. (machine 1200 x 1200 x 1500mm 1200 x 1400 x 1500mm 1200 x 1700 x 1500mm moved together with tools) (3‘11“ x 3‘11“ x 4‘11“) (3‘11“ x 4‘7“ 4‘11“) (3‘11“ x 5‘7“ 4‘11“) Length x Width x Height 782 –... -

Page 13: Spare Parts List

8 Spare parts list Customer Service Address: Customer Service Address in the USA CLEMENS GmbH & Co. KG CLEMENS Vineyard Equipment, Inc. Maschinenfabrik Rudolf-Diesel-Straße 8 224 N. East Street D-54516 Wittlich (Germany) Woodland, CA 95776 Phone: +49 (0) 65 71 / 929 -00 Phone: (530) 406-0577 Fax: +49 (0) 65 71 / 929 -193... -

Page 14: Basic Frame With Sliding Units And Hydraulic Width Adjustment (All Models)

8.2 Basic frame with sliding units and hydraulic width adjustment (all models) 9,9,9 8,8,8 2,3,4 10,10,10 1,3,4 7,7,7 6,6,6 Shearing screw Figure 10 Spare parts base unit HEXAGON 07.2019 en... - Page 15 Item no. Specification Remark Quantity Order no. Sliding block, high CL724.010001 Sliding block, flat CL724.010002 Adjusting screw CL724.010003 Seal CW780.025100 Sliding block Sliding unit rhs CL729.020001 Master cylinder for details see 8.3 CD895.580000 Master cylinder for details see 8.4 CL895.580000 Master cylinder for details see 8.5 CI895.580000...

-

Page 16: Master And Slave Cylinder For Hexagon 729

8.3 Master and slave cylinder for HEXAGON 729 38,40 47a 37 44 36 46 42 41 Figure 11 Spare parts cylinders HEXAGON 729 Item no. Specification Remark Quantity Order no. Cylinder pipe CL895.581000 Cylinder pipe CL895.591000 Piston rod CL895.582000 Bushing CL895.580001 Bushing CL895.590001... -

Page 17: Master And Slave Cylinder For Hexagon 723

8.4 Master and slave cylinder for HEXAGON 723 38,40 47a 37 44 36 46 42 41 39 Figure 12 Spare parts cylinders HEXAGON 723 Item no. Specification Remark Quantity Order no. Cylinder pipe CD895.581000 Cylinder pipe CD895.591000 Piston rod CD895.582000 Bushing CL895.580001... -

Page 18: Master And Slave Cylinder For Hexagon 724

8.5 Master and slave cylinder for HEXAGON 724 38,40 47a 37 44 36 46 42 41 39 Figure 13 Spare parts cylinder HEXAGON 724 Item no. Specification Remark Quantity Order no. Cylinder pipe CI895.581000 Cylinder pipe CI895.581000 Piston rod CI895.582000 Bushing CL895.580001 Bushing... -

Page 19: Extensions, Guard Rails, Lower Link Extension

8.6 Extensions, guard rails, lower link extension 2.1,2.2,2.3 1.1,1.2,1.3 Figure 14 Spare parts lower link extension Figure 15 Spare parts extension 4.1,4.2,4.3,4.4 Figure 16 Spare parts guard rail large Figure 17 Spare parts guard rail small Item no. Specification Remark Quantity Order no. -

Page 20: Disk Harrow With Mounting Frame

8.7 Disk harrow with mounting frame 12,13 15,16,17 22,23,24 19,20,21 Figure 18 Spare parts disk harrow with mounting frame Item no. Specification Remark Quantity Order no. Spindle adjustment CB941.550000 Mounting frame CA941.000000 Lower link bolt CW560.006000 Clamping pin CW520.004200 Upper link bolt CW003.001700 Locking pin CW520.000500... -

Page 21: Accessories For Disk Harrow

8.8 Accessories for disk harrow 1.4,1.5,1.6 2.2,2.3,2.4 1.1,1.9 Figure 20 Spare parts retrofit kit on 4 disks Figure 19 Spare parts mounting kit for land roller Item no. Specification Remark Quantity Order no. Retrofit kit on 4 disks complete for 2 elements CL941.264000 Square shaft, long for 4 disks... -

Page 22: Mounting Plates For: Radius, Central Tool, Chisel Body

8.9 Mounting plates for: RADIUS, central tool, chisel body 1.1,1.2,1.5 2.1,2.2,2.3 1.3,1.4 1.4,1.6 Figure 22 Spare parts mounting plate Figure 21 Spare parts mounting plate for RADIUS for central tool 3.1,3.2,3.3 Figure 23 Spare parts prolongation plate Item no. Specification Remark Quantity Order no. -

Page 23: Cultivator Tine C-Shaped With Clamp

8.10 Cultivator tine C-shaped with clamp 6.10 6.10 Figure 24 Spare parts Cultivator tine C-shaped wit clamp Item no. Specification Remark Quantity Order no. Cultivator tine C-shaped CW650.015600 Grubber share reinforced incl. screws and nuts items no. 3 and 4 CW650.015700 Duck foot share 310 mm incl. -

Page 24: Tine 80X25 Complete

8.11 Tine 80x25 complete Figure 25 Spare parts chisel body HEXAGON 07.2019 en... -

Page 25: Clamp For Pivoting Disc Colter On Tine 80X25

Tine complete (without optional parts items no. 3+4) Item no. Specification Remark Quantity Order no. Tine complete without items no. 3+4 CB941.300000 Individual parts Item no. Specification Remark Quantity Order no. Tine CB941.301000 Mount for chisel point CB941.302000 Wing sharer option CW651.000600 Chisel share... -

Page 26: Set Of Bison Tines For Ripping

8.13 Set of Bison tines for ripping Mounting side by side Mounting in line as in above drawing Figure 27 Spare parts bison tines HEXAGON 07.2019 en... - Page 27 Item no. Specification Remark Quantity Order no. Bison tine rhs complete without chisel point CL941.800001 Bison tine lhs complete without chisel point CL941.800002 Bison chisel point rhs CW650.017300 Bison chisel point lhs CW650.017400 Clamping sleeve 148116050 Hexagon head screw 093120070 Washer 012521 Hexagon nut...

-

Page 28: Frame For Land Roller With Spindle Adjustment

8.14 Frame for land roller with spindle adjustment 9,10 Figure 28 Spare parts frame for land roller Item no. Specification Remark Quantity Order no. for model 723, rollers up to 1330 mm (4’4”) 833 mm (2‘9“) wide Frame center section CB941.501000 square tube 478 mm (19“) long Bearing strap without bushing... -

Page 29: Land Roller Ø400 Mm (16") For Open Soil

8.15 Land roller Ø400 mm (16“) for open soil Figure 29 Land roller Specification Remark Quantity Order no. Total width 950 mm (3‘1“) Land roller CA940.490001 Total width 1105 mm (3‘8“) Land roller CA940.470001 Total width 1273 mm (4‘2“) Land roller CA940.480001 Total width 1600 mm (5‘3“) Land roller... -

Page 30: Support, Lower Link, Support Wheel Mount

8.17 Support, lower link, support wheel mount 2.3,2.4,2.5 2.1,2.2 3.2,3.3,3.4 1.1,1.2,1.3 Figure 31 Spare parts support Figure 33 Spare parts support Figure 32 Spare parts lower link wheel mount Item no. Specification Remark Quantity Order no. Support complete CL729.400000 Pressure spring not visible CW009.056500 Star knob... -

Page 31: Steel Support Wheel

8.18 Steel support wheel For the hydraulic CLEMENS support wheels, please request the separate spare parts list. Item no. 16 "adjusting washer" is not shown! Figure 34 Spare parts steel support wheel Item no. Specification Remark Quantity Order no. Support wheel complete CI903.700000 Support CI903.710000... -

Page 32: Support Wheel, Pneumatic

8.19 Support wheel, pneumatic For the hydraulic CLEMENS support wheels, please request the separate spare parts list. 11/11 Figure 35 Spare parts support wheel pneumatic HEXAGON 07.2019 en... - Page 33 Order numbers for the pneumatic wheel 15 x 6.00 - 6 are written in bold and black. Order numbers for the pneumatic wheel 16 x 6.50 x 8 are written in bold and green. All spare parts written in normal type apply to both support wheels. Item no.

-

Page 34: Oscillating Support Wheel, Pneumatic

8.20 Oscillating support wheel, pneumatic For the hydraulic CLEMENS support wheels, please request the separate spare parts list. Figure 36 Spare parts oscillating support wheel pneumatic HEXAGON 07.2019 en... - Page 35 Item no. Specification Remark Quantity Order no. Oscillating support wheel complete CE903.700000 Guide tube complete CC903.601100 Internal sliding tube complete CE903.701000 Spindle CC903.601001 Toggle support CL903.010002 Toggle CW031.000100 Conical lubricating nipple CW570.000100 Spring clip CW009.055000 Wheel support CE903.702000 Wheel shaft complete CW003.012400 Dust protection cover CW004.002700...

-

Page 36: List Of Illustrations

Figure 10 Spare parts base unit ..........................14 Figure 11 Spare parts cylinders HEXAGON 729 ....................16 Figure 12 Spare parts cylinders HEXAGON 723 ....................17 Figure 13 Spare parts cylinder HEXAGON 724 ....................18 Figure 14 Spare parts lower link extension ......................19 Figure 15 Spare parts extension ...........................

Need help?

Do you have a question about the HEXAGON 723 and is the answer not in the manual?

Questions and answers