Subscribe to Our Youtube Channel

Summary of Contents for Graymills TL-Series

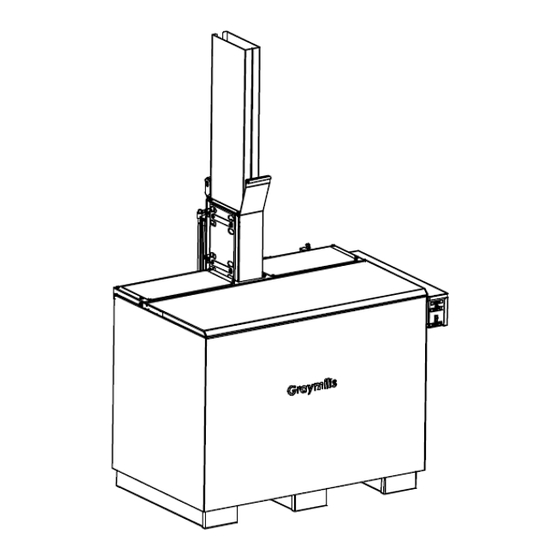

- Page 1 795-92429 GRAYMILLS GM 4-20 ® TL-SERIES LIFTKLEEN PARTS CLEANERS — AQUEOUS/SOLVENT Operations and Maintenance Instructions TL-17 SOLVENT PARTS CLEANER TLHS-18 AQUEOUS PARTS CLEANER...

- Page 2 SAFETY WARNINGS You will find various types of safety information on the following pages and on the labels attached to Graymills equipment. The following Safety Statements explain their meaning: This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid personal injury or death.

-

Page 3: Specifications

If you have any questions regarding the correct fluids to use in this unit, call Graymills at (773) 248-6825 and ask for Customer Service. These units have moving parts, pinch-points and close tolerances. Always stand clear of lift platform (Fig.4D) and lid (Fig.4D) when operating as the lid could unexpectedly... -

Page 4: Installation

Provide the required compressed air supply to the installation (Figs.3B,3C) as shown in Fig. 3 (Figs.5B,5C). site. Although the TL-SERIES is equipped with a 1/4" air After the air supply is connected, slide the sleeve valve connection, it is recommended that a 3/8" to 1/2" supply be forward toward the machine to turn on the air supply. - Page 5 temperature control knob on the heater control panel (Fig.4D) to the uppermost position, opening the lid (Fig.4A). (Fig.1B) slowly clockwise to desired setting. A click will be Load the parts to be cleaned in a parts basket and place heard and the signal light should come on indicating that the the basket on the lift platform (do NOT exceed weight limit).

- Page 6 The pump motor (Fig.1A) is equipped with sealed ball bearings and requires no additional lubrication. o A Graymills Oil Separator may be used to perform continuous oil separation during operation. V-Groove Roller Maintenance o A Graymills Turbo Boost Filtration System (Models TBF Remove clips (Fig.8E) from one side of housing on all four...

-

Page 7: Troubleshooting Guide

Increase air pressure to 100 psig comes to top and lid If your problem is not listed above or problems persist, please contact Graymills for further assistance. 1-888-472-9645 REPLACEMENT PARTS LIST TL-17 AND TLHS-18 LIFTER KIT ASSEMBLY PUMP AND MOTOR (OPTIONAL) -

Page 8: Warranty

Graymills’ warranty the original manufacturer’s warranty, provided that Buyer obligations and Buyer’s remedies thereunder (except as to gives Graymills prompt notice of any defect or failure and title) are solely and exclusively as stated herein. In no case satisfactory proof thereof. - Page 9 Fig3. FILTER/REG. Fig4 (TL17) Fig 1.(TLHS18) Fig 2. (TL17) (TLHS18 BOX) (TL17 BOX) Fig5 Graymills...

- Page 10 Fig 6 (TLHS18) Fig 7(TL17)

- Page 11 Fig. 8 V-Roller Detail 431-41161 COVER 761-92495 V-GROOVE ROLLER 573-41187-41 SPACER 569-41175-88 SHAFT 756-06286-88 CLIP 647-41189-81 FACTORY SET-PLATE Fig. 9 Fuse Link; (9A-9F) & Cushion (9G) 9A) 451-24446 SAFETY LINK ASSY 9B) 735-03018-41 MALE CONN 9C) 754-00600-88 WASHER 9D) 724-02777-41 PIPE COUPLING 9E) 735-06259 ELBOW TUBE/ NPT...

Need help?

Do you have a question about the TL-Series and is the answer not in the manual?

Questions and answers