Table of Contents

Advertisement

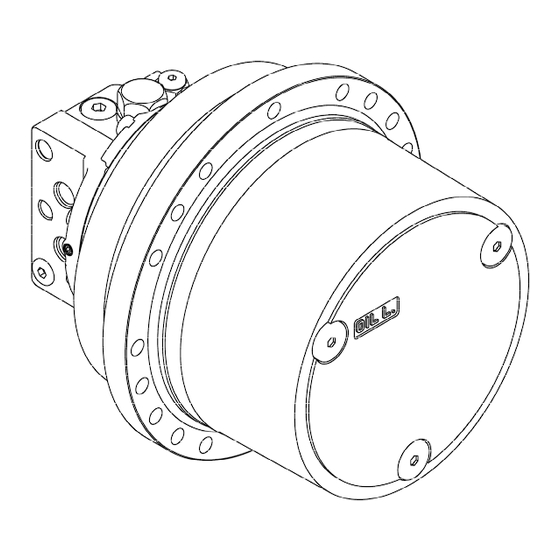

GM Series

Hydraulic Motor with Reduction

Operation Manual

Please be sure to read and understand this manual before using the product

The administrator and operator of the product should have access to this manual.

Store this manual at a specified safe place so that it can be referred to when necessary.

TM19040

First Edition (1019)

Gears

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Nabtesco GM Series

- Page 1 TM19040 First Edition (1019) GM Series Hydraulic Motor with Reduction Gears Operation Manual Please be sure to read and understand this manual before using the product The administrator and operator of the product should have access to this manual. Store this manual at a specified safe place so that it can be referred to when necessary.

-

Page 2: Table Of Contents

GM Series TM19040 P.2/31 Table of Contents CONTENTS OF MANUAL ......................3 IMPORTANT NOTICE ........................4 Intended Use of Product ...................... 4 Precautions for Safe Use of GM..................4 Notice on the Operation Manual..................5 Disposal of GM ........................5 Other Important Notice ...................... -

Page 3: Contents Of Manual

・ Replacing interval and procedure MAINTENANCE & Precautions for maintenance and inspection works, and procedure of Ch.6 INSPECTION periodical inspection and GM removal are described. Ch.7 TROUBLESHOOTING How to deal with problems is described. CUSTOMER SUPPORT Support contact at Nabtesco is described. -

Page 4: Important Notice

IMPORTANT NOTICE Intended Use of Product GM Series; Hydraulic Motor with Reduction Gears (hereafter referred to as GM) is a hydraulic driven rotary actuator. The product contains a reduction gears, a hydraulic motor, a brake valve and a parking brake integrated into one compact unit. It has been developed for use as an actuator for application requiring low-rpm, high torque operation such as construction and marine machinery. -

Page 5: Notice On The Operation Manual

Any operation neglecting the described specification or recommendation may cause accidents and/or damage. This manual is copyrighted and all rights are reserved by Nabtesco. Any part of the drawings and technical references including in this manual shall not be copied, photocopied, or reproduced to any electronic medium or machine-readable form without prior consent of Nabtesco. -

Page 6: Chapter 1 Safety

GM Series TM19040 P.6/31 The safety precautions are to be guidelines to avoid human accidents during the transportation, installation, and maintenance of GM, as well as to avoid damage to GM. 1.1. Strict observance and Prohibition Overall precautions are classified into strict observance and prohibition. -

Page 7: Types Of Warnings And Their Meanings

GM Series TM19040 P.7/31 1.2. Types of Warnings and their Meanings The following four types of warnings are used according to the expected hazards during operation and maintenance of the product. Neglecting such safety rules and warnings may cause accidents, resulting in serious injury and/or damage to this product. -

Page 8: Chapter 2 Overview Of Gm

GM Series TM19040 P.8/31 2.1. Name of Each Part Here is an explanation of the name of each part. NOTE The following illustration may not strictly represent the actual appearance of the product ordered. Oil Fill Port Main Port Pilot Port... -

Page 9: Storage Of Gm

GM Series TM19040 P.9/31 2.2. Storage of GM NOTICE When storing the product, follow the same packing condition as before unpacking. If the packaging conditions change, foreign matter may enter inside or rust may occur. To avoid rust, corrosion, and deterioration of seals, avoid storage in places such as: •... -

Page 10: Chapter 3 Preparation For Installation

Safety Datasheet, contact our customer support or the supplier of the hydraulic oil. Lubricant GM is filled with the lubricant specified by Nabtesco at the factory. For detailed information on the lubricant, refer to Chapter 5 (p.19) and the Safety Datasheet. For the Safety... -

Page 11: Transportation And Unpacking

GM Series TM19040 P.11/31 3.3. Transportation and Unpacking 3.3.1 Transportation WARNING • The mass of GM is heavy. Be sure to use transportation equipment such as a forklift to transport GM units. • In transporting GM, handle it with ample care to avoid drops or falls. Otherwise it may result in injuries of the operator or damage to GM. - Page 12 • Reduction gears of GM is filled with lubricant specified by Nabtesco at the factory. • When hoisting GM, refer to the Hoisting GM section (Sections 4.1 and 4.2 on p.14 and p.15).

- Page 13 GM Series TM19040 P.13/31 NOTE At the time of delivery, covers or plugs are attached to ports of the product to prevent contamination from entering inside. (They are not shown in the confirmation notice.) Do not remove it during storage, and remove it when connecting pipes.

-

Page 14: Chapter 4 Installation In The Machine

GM Series TM19040 P.14/31 4.1. Precautions on Hoisting CAUTION • The crane operation during hoisting must be conducted by a qualified person. • Be sure to wear a helmet, leather gloves and protective footwear during hoisting work. • The mass of GM is heavy. Use a hoisting tool robust enough to endure the mass of GM. -

Page 15: Hoisting And Installing Gm

GM Series TM19040 P.15/31 4.2. Hoisting and Installing GM Step 1 Attach the hoisting tool to GM. Step 2 Hoist GM body. Driving part Machine (5) Bearing surface (2) Bearing surface (4) Mounting surface for driving part (1) Mounting surface... - Page 16 GM Series TM19040 P.16/31 Step 4 Align (3) mounting bolt hole for equipment of GM with the mounting holes of the machinery, and assemble GM into the machinery. NOTICE During the installation, do not hit GM with a hammer and the like.

-

Page 17: Hydraulic Piping Connection

GM Series TM19040 P.17/31 NOTICE Use the specified number of GM mounting bolts and tighten with the specified tightening torque. Otherwise, not only GM may not provide its performance but also the customer machine and GM may be damaged. Step 10 Tighten the driving part mounting bolts uniformly with the specified tightening torque. - Page 18 GM Series TM19040 P.18/31 CAUTION • Never approach the rotating part during machine operation. Person(s) may be caught by the rotating part, causing fatal accidents. • GM may become hot during operation. After stopping the operation, do not touch GM until it has cooled down.

-

Page 19: Chapter 5 Hydraulic Oil And Lubricant

GM Series TM19040 P.19/31 This chapter describes hydraulic oil and lubricant. The description on hydraulic oil and lubricant (this chapter) in this document should be reflected at least to the operation manual for the customer’s machine into which GM is incorporated. -

Page 20: Type Of Hydraulic Oil

Use the hydraulic oil recommended by us. Use of any other hydraulic oil may degrade the performance and durability of GM. Hydraulic oil specified by Nabtesco • Use a wear-resistant hydraulic oil with a viscosity equivalent to ISO VG32 to VG46. -

Page 21: Replacing Hydraulic Oil

GM Series TM19040 P.21/31 Filling volume of hydraulic oil Prepare hydraulic oil according to the amount of hydraulic oil described in the confirmation notice. Temperature and viscosity range of hydraulic oil Make sure that the operating temperature range and viscosity range of the hydraulic oil do not exceed the following ranges. -

Page 22: Type Of Lubricant And Filling Volume

Use the lubricant recommended by us. Use of any other lubricant may degrade the performance and durability of GM. Lubricant specified by Nabtesco Use a lubricant with extreme-pressure additive equipment to SAE # 90 (API class GL-4 or higher).The following brands are recommended. -

Page 23: Replacing Lubricant

GM Series TM19040 P.23/31 5.5. Replacing Lubricant Replacement interval • Replace with new oil at 500 engine hours first, after that every 1000 engine hours. Replace the lubricant if it has been in stock for a long time (1 year or more). - Page 24 GM Series TM19040 P.24/31 NOTICE Use the same lubricant brand for replacement and replenishment, and do not mix different brands. When changing the oil type, flush the inside of reduction gears. Replace or replenish the lubricant according to the following procedure. Also, work with GM in the posture with the oil fill port up and the oil drain port down as shown below.

- Page 25 GM Series TM19040 P.25/31 NOTE If the lubricant is filled up excessively, the inner pressure increases, which can cause a leakage of the lubricant or damage to the oil seal. When the lubricant is small in amount, insufficient lubrication may cause damage to GM.

-

Page 26: Chapter 6 Maintenance & Inspection

GM Series TM19040 P.26/31 & & This chapter describes the maintenance and inspection. Reflect at least the description on maintenance & inspection (this chapter) in this document to the operation manual for the customer machine into which GM is incorporated. - Page 27 GM Series TM19040 P.27/31 6.2.1. Checking for lubricant leakage Visually check the periphery of the reduction gears, joint surface with the machine, and the entire machine to make sure that there is no leakage of the lubricant. If a leakage of the lubricant has been found, identify and remove the cause, and then replenish the lubricant.

-

Page 28: Removal From The Machine

GM Series TM19040 P.28/31 Step 1 Using a surface thermometer, measure the surface temperature at the measurement point shown in the following figure below and the surrounding area to check the maximum value. ② ① ③ ①、②:Hydraulic motor temperature measurement point ※②... -

Page 29: Chapter 7 Troubleshooting

GM Series TM19040 P.29/31 If there is any problematic phenomenon, check the cause and take measures according to the following table. If the measure marked with a circle is needed, stop the machine operation and contact our customer support. For the item marked with a circle, contact our customer support. - Page 30 GM Series TM19040 P.30/31 Phenomenon 1 Phenomenon 2 Possible cause Countermeasure Lack of lubricants Replenish to proper amount. ○ The surface temperature of the reduction gears is high Pitting occurs in bearings and gears Replace GM. ○ Hydraulic oil enters the gear case Replace the oil seal and lubricants.

-

Page 31: Customer Support

GM Series TM19040 P.31/31 For inquiries related to products and servicing, please contact customer support (see the following addresses): For inquiries, be ready to provide the product information described on the nameplate attached on the product. Nabtesco Corporation Head office...

Need help?

Do you have a question about the GM Series and is the answer not in the manual?

Questions and answers