Table of Contents

Advertisement

SINCE 1969

PBM SUPPLY & MFG., INC

OWNER'S / OPERATOR'S MANUAL

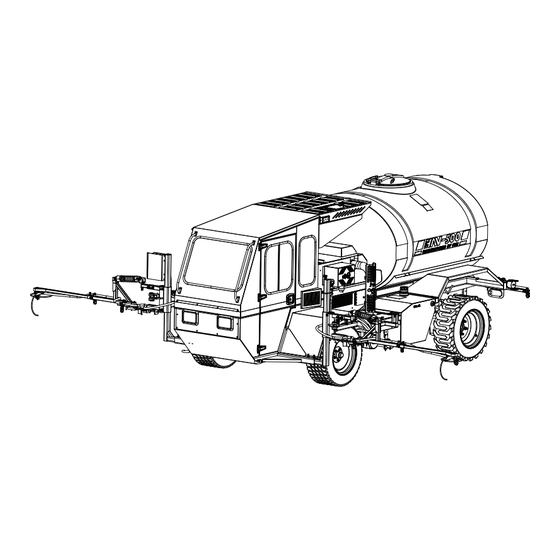

Tier 4 HAV Self-Propelled Sprayer

California Proposition 65 Warning

WARNING: This product contains chemicals known to

the state of California to cause cancer, and birth defects

or other reproductive harm.

www.p65warnings.com

Read the Operator's Manual entirely. When you see

this symbol, the subsequent instructions and

P/N: HAV-OM

warnings are serious - follow without exception.

Effective: March 16, 2020

Your life and the lives of others depend on it!

Advertisement

Table of Contents

Summary of Contents for PBM HAV Series

- Page 1 SINCE 1969 PBM SUPPLY & MFG., INC OWNER’S / OPERATOR’S MANUAL Tier 4 HAV Self-Propelled Sprayer California Proposition 65 Warning WARNING: This product contains chemicals known to the state of California to cause cancer, and birth defects or other reproductive harm.

-

Page 2: Table Of Contents

Table Of Contents SINCE 1969 PBM SUPPLY & MFG., INC Table Of Contents Introduction ............ 3 Checking Radiator Hoses ........26 Checking The Air Filter ........27 Application ............. 3 Draining The Fuel-Water Separator ....28 Identification ..........3 Inspecting The Crank Case Breather Tube..28 Booms &... -

Page 3: Introduction

PBM SUPPLY & MFG., INC Introduction Congratulations on the purchase of your new PBM sprayer. We are confident that you will be satisfied with the build quality and performance of your sprayer. The purpose of this manual is to instruct operators how to safely operate and maintain the sprayer so that it will last for years to come. -

Page 4: Important Safety Information

SINCE 1969 PBM SUPPLY & MFG., INC Important Safety Information It is important to carefully read and understand this manual and any included manuals prior to operating PBM equipment. Safety Alert Symbol The safety alert symbol indicates there is a potential hazard to personal safety involved and extra safety precaution must be taken. -

Page 5: Safety Precautions For Children

Important Safety Information SINCE 1969 PBM SUPPLY & MFG., INC equipment. • Never run the sprayer in high range with chemical in the tank. • Keep all bystanders away from equipment and work area. • Start sprayer from drivers seat with hydraulic controls in neutral. -

Page 6: Transport Safety

Important Safety Information SINCE 1969 PBM SUPPLY & MFG., INC • When inflating tires, use a clip on chuck and extension hose long enough to allow you to stand to the side and NOT in front of the tire assembly. -

Page 7: Proper Personal Protective Equipment (Ppe)

Consult the chemical container of the products you will be using in your sprayer. Adhere to all safety warn- ings and recommendations. Use Seat belts • PBM recommends the use of a seat belt. Using a seat belt will reduce the risk of serious injury or death if the vehicle rolls. Keep Riders off of Machinery •... -

Page 8: Safety Labels

• Replace damaged or worn safety labels. • Refer to this section for proper label placement. Order new labels from your closest PBM dealer, or contact the nearest PBM Supply & MFG., Inc. location. • New accessories and/or repair items may require safety labels to be applied to them. Be sure to apply the proper safety labels if replacing components. - Page 9 Safety Labels SINCE 1969 PBM SUPPLY & MFG., INC Part Number: SW4 Description: Read the operator’s manual before operation. Part Number: SW501 Description: Explosion Hazard Symbol Explanation: This symbol represents the need to keep open flames away from the area.

- Page 10 Safety Labels SINCE 1969 PBM SUPPLY & MFG., INC Part Number: SW500 Description: Explosion Hazard Symbol Explanation: This symbol represents the need for proper training prior to service. Part Number: SW900 Description: Toxic Chemical Hazard Symbol Explanation: Wear Rubber Gloves, Don’t Breather Vapor, Don’t Ingest Chemical...

- Page 11 Safety Labels SINCE 1969 PBM SUPPLY & MFG., INC Part Number: SW901 Description: Agricultural chemicals can be dangerous. Part Number: WARNING ROLL OVER HAZARD WARNING ROLL OVER HAZARD To avoid serious injury or death, avoid abrupt manouvers and excessive speed.

- Page 12 Safety Labels SINCE 1969 PBM SUPPLY & MFG., INC Part Number: NOTICE AIR BAG NOTICE AIR BAG PRESSURE 35 PSI MINIMUM 95 PSI MAXIMUM P/N: NOTICE AIR BAG Description: Air Bag Pressures Symbol Explanation: This symbol represents the air ride pressure gauge.

-

Page 13: Operating Instructions

Operating Instructions SINCE 1969 PBM SUPPLY & MFG., INC Operating Instructions Sprayer setup and operation will be covered in this section. Refer to the following diagrams for the location of controls . Dashboard Controls 1. Backup camera display 13. Head light on/off switch 2. -

Page 14: Control Lever Controls

Operating Instructions SINCE 1969 PBM SUPPLY & MFG., INC Control Lever Controls Control lever switch positions may differ slightly depending upon the boom type the sprayer is configured with. (Combination boom with boomless nozzle shown). 20. Left boom up/down, or accessory boomless nozzle 21. -

Page 15: Preparing To Operate The Hav Sprayer

Operating Instructions SINCE 1969 PBM SUPPLY & MFG., INC Preparing To Operate The HAV Sprayer • Conduct all safety checks. • Adjust the operator / driver seat for easy reach of all controls. • Fasten the seat belt. • Check that the hydraulic control is in the neutral position. -

Page 16: Setting The Boom Width

1. The diagram below shows an example of how an unmodified spray boom will come configured from PBM. The outer most nozzle should be 30” from the center of the tree or the end of the offset spray pattern. - Page 17 Operating Instructions SINCE 1969 PBM SUPPLY & MFG., INC 30” 20” 20” 20” 20” E ective Spray Pattern Center Of Tree 2. For spraying the strips of an orchard, you will use only the outer most spray nozzles on the outside boom arms.

-

Page 18: Testing The Spray System

Operating Instructions SINCE 1969 PBM SUPPLY & MFG., INC Testing the Spray System It is VERY important to test the sprayer with plain water before any chemical is added to the tank. This will al- low the operator to check the sprayer for leaks or damage and make any necessary repairs before adding spray chemicals to the system. -

Page 19: Flushing The Pump

Operating Instructions SINCE 1969 PBM SUPPLY & MFG., INC Flushing the Pump HAV sprayers are fitted with a 3-way valve on the rear of the sprayer to allow the operator to shut off the supply of material from the tank and flush the pump and spray lines with fresh water from the garden hose connec- tion. -

Page 20: Transportation

Operating Instructions SINCE 1969 PBM SUPPLY & MFG., INC Transportation Trailer Transportation HAV sprayers are designed with tie down hooks for transport on trailers. Chain binders and sufficiently rated chains should be used when securing the sprayer for transport. HAV sprayers should only be transported on trailers with their sprayer tank EMPTY. -

Page 21: Jump Starting The Hav

Operating Instructions SINCE 1969 PBM SUPPLY & MFG., INC Jump Starting The HAV If the HAV cannot be started because the battery is out of charge, it can be jump started from another battery. • Use high quality jumper cables and make sure all connections are clean and have a solid connection. -

Page 22: Maintenance

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC Maintenance Proper service intervals and adjustments are essential to prolonging the life of your sprayer, follow the guide- lines and service procedures in this manual to avoid costly downtime. Warning. To avoid serious injury or death: •... -

Page 23: Service Schedule

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC Service Schedule This chart shows the recommended service intervals for the different systems on your HAV sprayer. Follow the procedures shown in Service Procedures section of this manual to prolong the life of your sprayer. -

Page 24: Service Procedures

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC Service Procedures Re-torquing The Rear End Suspension Bolts The rear end suspension bolts should be re-torqued after the first 100 hours of operation and every 500 hours thereafter. • Locate the panhard bar and trailing arm bolts shown in the diagram below and re-torque to 460 ft lbs. A torque multiplier may be required to achieve the 460 ft lb rating. -

Page 25: Checking The Spray System

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC • Open the hydraulic tank valve and run the engine for 5 minutes. Turn off engine. • Fill the hydraulic oil tank to the center of the site glass located on the side of the hydraulic tank. -

Page 26: Changing Radiator Coolant

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC Changing Radiator Coolant The radiator coolant should be changed every 2000 hours, or 2 years. It is a good idea to replace the radiator hoses and clamps when changing the coolant. •... -

Page 27: Checking The Air Filter

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC Replacing Radiator Hoses And Clamps The radiator hoses and clamps should be replaced every 2000 hours or 2 years. • Begin by parking the sprayer on a flat and level surface. •... -

Page 28: Draining The Fuel-Water Separator

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC Draining The Fuel-Water Separator The fuel-water separator should be drained prior to every use to extend the life of the engine. • Untwist the drain port located on the bottom of the fuel-water separator. -

Page 29: Changing Engine Oil

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC Changing Engine Oil The engine oil should be replaced every 400 operating hours. • Begin by parking the sprayer on a flat and level surface. • Place a drain pan under the engine and remove the drain plug from the oil pan. -

Page 30: Replacing The Fuel-Water Separator

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC • Park the sprayer on flat level ground and secure the sprayer with wheel blocks. • Place an adequately sized drain pan under the fuel tank and remove the drain plug. •... -

Page 31: Replacing Fuel Pipes And Clamps

Disconnect the fuel lines. • Replace the fuel lines with new fuel lines from your local PBM dealer. Inspecting The Battery And Cables The battery should be inspected every 500 hours or 6 months. The battery is located in the fender access panel on the right hand side of the machine. -

Page 32: Replacing The Air Tank

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC escape. • Shut the drain port. Replacing The Air Tank The pressurized air tank should be replaced every 2 years. • Completely drain the air tank. • Remove the air lines from the push-to-connect fittings. -

Page 33: Preparing The Hav For Storage

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC Preparing The HAV For Storage Before storing the HAV sprayer for the season, it is important to prepare it for storage using the following procedures. If the machine is not used for a long period of time, it is good practice to start the engine and run it for about 5 minutes under no-load conditions every 2-3 months. -

Page 34: Common Replacement Parts

PBM SUPPLY & MFG., INC Common Replacement Parts Reference the table below for common replacement parts. If you cannot find the components you are looking for in this table, contact your nearest PBM sprayer dealer for assistance. Component Part Number... -

Page 35: Front End Replacement Parts

Maintenance SINCE 1969 PBM SUPPLY & MFG., INC ... -

Page 36: Warranty

PBM Supply & Mfg., Inc or not, authorized to do so on our behalf. Call (530) 345-1334 with any questions regarding this limited warranty. -

Page 37: Vehicle Specifications

Vehicle Specifications SINCE 1969 PBM SUPPLY & MFG., INC Vehicle Specifications Specifications listed on this page are for the base unit without accessories or spray booms. Additional accesso- ries may affect the specifications listed on this page. Vehicle • Fuel Tank ..............30 Gallons (US) •... -

Page 38: Service Records

Service Records SINCE 1969 PBM SUPPLY & MFG., INC Service Records Date Engine Hours Service Technician PBM Supply & MFG., Inc. www.pbmsprayers.com 324 Meyers St. Chico CA 95928 1-800-688-1334... - Page 39 Service Records SINCE 1969 PBM SUPPLY & MFG., INC Date Engine Hours Service Technician PBM Supply & MFG., Inc. www.pbmsprayers.com 324 Meyers St. Chico CA 95928 1-800-688-1334...

- Page 40 SINCE 1969 PBM SUPPLY & MFG., INC PBM Supply & MFG., Inc. - Chico, CA (Headquarters) 324 Meyers Street, Chico, CA 95928 Phone: 530-345-1334 Fax: 530-345-9903 E-Mail: pbm@pbmsprayers.com Website: www.pbmsprayers.com PBM Supply & MFG., Inc. - Yuba City, CA 955 N. George Washington Blvd.

Need help?

Do you have a question about the HAV Series and is the answer not in the manual?

Questions and answers