Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Seallence Winma-L100

- Page 1 Working Manual Seallence Page 1...

-

Page 2: Table Of Contents

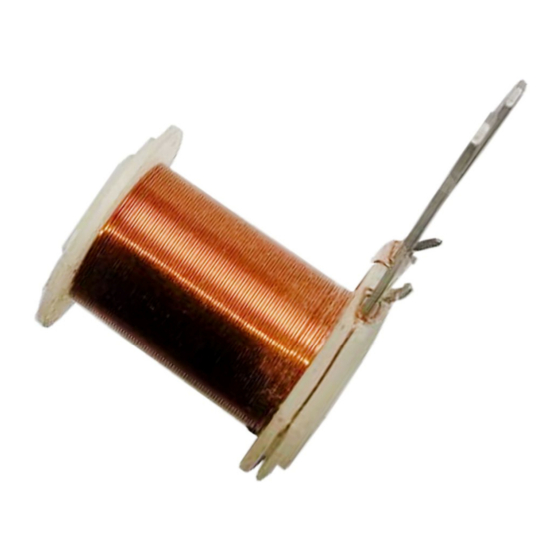

INTRODUCTION INTRODUCTION Winma-L100 is a linear winding machine made to wind the coils with wire gauge of 0.01mm – 1.00mm. The x-axis movement i.e. maximum traverse movement is 99.9mm. The machine is controlled by electronics and the software specially designed for this machine. - Page 3 In the second case the machine initializes to the winding position set in the program, which is selected for winding. In the third case, the machine is already in the middle of winding. So by pressing ‘START’ switch the user can continue the winding process. Seallence Page 3...

-

Page 4: Edit

= Tap turns 12. TR START:000.0mm = Traverse start point 13. START POSN: LFT = Traverse start position 14. AUTO HOME: NO = Auto home after winding complete 15. NEXT PROG :000 = Next Program for cascading Seallence Page 4... -

Page 5: Parameter Detail

The ‘AUTO’ led gets ‘ON’ on the front panel, when this auto start the next program menu is set to ‘YES’ condition. After editing last (16 ) parameter press enter to save the program. Then the display will show ‘SAVING DATA...’ Seallence Page 5... -

Page 6: Parameter Setting

= After 999.8 turns, the brake apply and releases for every 0.1 turn of spindle. 11. TAP[01]: 00000.0 = No taping option is enabled. 12. TR START:010.0mm = Traverse moves 10.0mm right for the winding operation. 13. START POSN: LFT = Traverse starts from left. Seallence Page 6... -

Page 7: Copy

SORCE PROG :000 = Edit the program number from where the data has to be copied. DESTN PROG :000 = Edit the program number to which the data has to save. Edit and press ‘ENTER’ key, then the data will copy and the display shows ‘COPYING...’ Seallence Page 7... -

Page 8: Run

E = END (Winding Complete) F = Power fail The machine stops because of following reasons 1. Winding turns are completed. 2. Turns equal to taping turns. 3. Layer stop function is activated. 4. Stop key is pressed. Seallence Page 8... -

Page 9: Special Functions

RESET MEMORY: To erase complete memory fallow the below procedure o Switch off the machine. o Press and hold the ‘RESET’ key. o Switch on the machine. The “RESET MEMRY: NO” option will display. Select ‘YES’ to erase and ‘NO’ to not erase and press ‘ENTER’. Seallence Page 9... -

Page 10: Shortcut Operation

To go back to previous menu in editing, press ‘STOP’ switch. e. Speed increment and decrement: Speed can be varied in running operation by pressing keys. To increase and decrease the speed, press ‘UP’ and ‘DOWN’ key respectively. Seallence Page 10... -

Page 11: Machine Details

Working Manual 5. 5. 5. 5. MACHINE DETAILS MACHINE DETAILS MACHINE DETAILS MACHINE DETAILS Front face: Back face: Seallence Page 11... - Page 12 Belt Size: 1. Low speed = motor to idler pulley = 345mm Idler to spindle pulley = 470mm 2. Medium speed = motor to spindle pulley = 570mm 3. High speed = motor to spindle pulley = 365mm Seallence Page 12...

-

Page 13: Belt Position

Working Manual BELT POSITIONS: BELT POSITIONS: BELT POSITIONS: BELT POSITIONS: 1. Low speed belt: 100 – 650 rpm 2. Medium speed belt: 400 – 3500 rpm 3. High speed belt: 1000 – 8000 rpm (Recommended < 80%) Seallence Page 13... -

Page 14: Calculatios

(deceleration time) and 10 (brake point) parameter properly according to the (brake point) parameter properly according to the winding turns and speed. winding turns and speed. For more details contact For more details contact: 9964477934/9538594642/9844667565 Email- seallenceproducts@gmail.com seallenceproducts@gmail.com Seallence, Bengaluru Seallence Page 14...

Need help?

Do you have a question about the Winma-L100 and is the answer not in the manual?

Questions and answers