Table of Contents

Advertisement

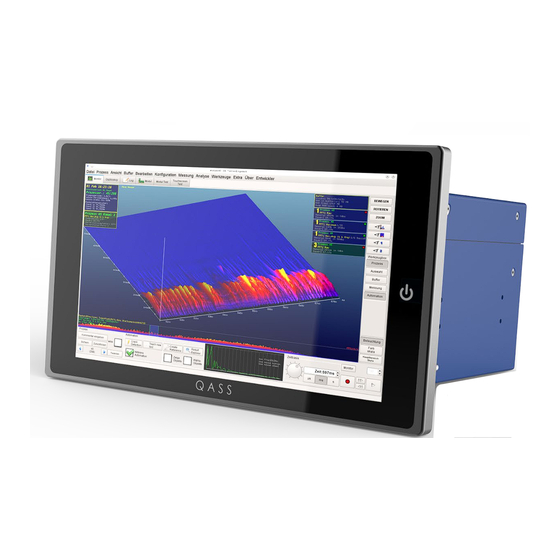

Optimizer4D Technical Specifications

Please find the detailed Manual on www.qass.net/wp/support/downloads/?lang=en

QASS GmbH

Quality Automation Systems Software

Schoellinger Feld 28

58300 Wetter, Germany

Tel.: +49 (0) 2335 8020-0

Fax: +49 (0) 2335 8020-20

Volksbank Bochum Witten eG

info@qass.net

www.qass.net

BLZ: 430 601 29

Ust-IdNr.: DE215478481

Kto.: 861 482 400

BIC: GENODEM1BOC

Commercial Register:

IBAN:

Hagen HRB 5423

DE21430601290861482400

CEO: Ulrich Seuthe

Advertisement

Table of Contents

Summary of Contents for Qass Optimizer4D

- Page 1 Optimizer4D Technical Specifications Please find the detailed Manual on www.qass.net/wp/support/downloads/?lang=en QASS GmbH Quality Automation Systems Software Schoellinger Feld 28 Volksbank Bochum Witten eG BIC: GENODEM1BOC info@qass.net Commercial Register: 58300 Wetter, Germany www.qass.net BLZ: 430 601 29 IBAN: Hagen HRB 5423 Tel.: +49 (0) 2335 8020-0...

-

Page 2: Table Of Contents

QASS µmagnetic sensor QASS µmagnetic power amplifier QASS µmagnetic electrical characteristics QASS µmagnetic connectivity options Screen Installation of screen Installing Optimizer4D into a wall cabinet Installing Optimizer4D into control cabinet Casing varieties Measurements / weight Carrying casing „QASE“ Memory options... -

Page 3: Overview

It‘s possible to connect Optimizer4D to a notebook via USB or Ethernet, in order to transfer measuring data. 131,4 197,8 Casing of Optimizer4D. From left to right: Back, upside, front and isometrical view. Dimensions are shown in millimeters. 3 / 27... -

Page 4: Qass Optimizer4D Electrical Characteristics

Optimizer4D Technical Specifications Electrical characteristics Basic specifications Device Optimizer4D Measuring device Power supply DC 10 - 28 V Nominal current 6,25 - 12 A Performance 150 W Ambient temperature 0 - 50° Celsius Type of protection IP 3X Casing Protection class (IEC 417) -

Page 5: Connectivity Options

Optimizer4D Technical Specifications Connectivity options 1. GB Ethernet I/O-Ports: If you use an output-port of any kind (I/O 4 or 2. Power connector (for use with power adapter or for direct Output 3), it‘s essential to bridge the three GND (ground) connection to power supply via machine) connectors. -

Page 6: I/O-Port Allocation

Optimizer4D Technical Specifications I/O-Port allocation Port PLC feature Comment Input 1 Power Switch ON1 Works as Power-on-switch when combined with ON2 Input 1 Start Measuring at position 1 Input 1 Start Measuring at position 2 Input 1 Start Measuring at position 3... -

Page 7: Harddrive Exchange

Optimizer4D Technical Specifications Harddrive exchange 1. Remove the cover of the PLC connectors at the back of the device by loosening 2 screws (1). 2. Unscrew the screws that hold the harddrives in place (2). 3. Remove and exchange harddrives (3). -

Page 8: Measuring Chain

Pos. Function 12/24 V Input Potential equalization Measuring chain The measuring chain of Optimizer4D consists of a sensor (shown left in the image), a connector from sensor to pre-amplifier, the pre-amplifier itself and a pre-amplifier-cable (green) from pre- amplifier to Optimizer4D. -

Page 9: Qass Optimizer4D & Μmagnetic Pre-Amplifier

The preamplifier has protection class IP67. Preamplifier cable A cable connection with an Ethernet Optimizer4D pre-amplifier with six inputs. Dimensions are shown in millimeters. cable is established from the preamplifier Dept. Technical reference Created by Approved by Dept. - Page 10 Microdot-Sensor (QWT-Micro - CiS.01) Title DWG No. QWT Zusammenbau QWT-MCX Following installation and commissio- Rev. Date of issue Sheet ning, Optimizer4D executes a self-test, Dept. Technical reference Created by Approved by Olaf Specht 18.12.2017 15.5 in order to determine if the sensors are ähnl.

-

Page 11: Qass Optimizer4D Sensors & Adapter

Optimizer4D Technical Specifications Magnetic adapter for sensor Magnetic Adapter. Dimensions are shown in millimeters. 11 / 27... - Page 12 Following installation and commissio- ning, Optimizer4D executes a self-test, in order to determine if the sensors are Sensor cable with MCX connectors The standard cable will be delivered with an correctly installed, among other things.

-

Page 13: Qass Μmagnetic Sensor

Magnetic field sensor for hardness testing and of a magnetic field coil that produces the excitation field. During the hardness testing, QASS µmagnetic magnetizes the compenent. Consequently, jumps occur in the strength of the magnetic field. The system records these jumps in real-time. -

Page 14: Qass Μmagnetic Power Amplifier

Optimizer4D Technical Specifications QASS µmagnetic power amplifyer µM-PA This power amplifyer is installed bet- O-PA ween measuring computer and sensor. Power amplifyer for hardness testing The connection cable has a length of up to five meters. Power amplifyer cable Connection is established with a scree- ned 8-pin cable. -

Page 15: Qass Μmagnetic Electrical Characteristics

Optimizer4D Technical Specifications Electrical characteristics QASS µmagnetic sensor General characteristics Device QASS µmagnetic sensor Supply Voltage DC 10 - 20 V (typ. 12 V) AC 10 - 18 V Signal Out Max. 30 mA Saturation magnetic field Max. 1,2 T Sensor temperature range -20°C to +70°C (-4°... -

Page 16: Qass Μmagnetic Connectivity Options

Optimizer4D Technical Specifications QASS µmagnetic connectivity O-CC WTA Längen: 1,0 / 2,5 / 5,0 m Längen: 1,0 / 2,5 / 5,0 m ,5 / 5,0 m O-CC VVK Längen: 3,0 / 5,0 / 10 m A ( 1 : 1 ) O-CC WTA Längen: 1,0 / 2,5 / 5,0 m... -

Page 17: Screen

Optimizer4D Technical Specifications Screen „Y“ Screen Connectivity 320,00 12 V DC „Y“ Bildschirmanschlüsse Display Port 12 V DC 320,00 DisplayPort HDMI HDMI Bildschirmanschlüsse 12 V DC USB 3.1 DisplayPort HDMI Connection to USB 3.1 USB 3.1 Connection to the Optimizer „X“... -

Page 18: Installation Of Screen

Optimizer4D Technical Specifications Installation of screen 4x M5 4x M4 1 : 2 Oberfläche: Härte: Maßstab: Angaben in Millimeter ISO 1302 Schutzvermerk ISO 16016 beachten Toleranz: ISO 2768 - Datum Name Nilges 13.12.2016 Gezeichn. Kontroll. Norm TechData-Bildschirm Rev.: Status Änderungen... -

Page 19: Installing Optimizer4D Into A Wall Cabinet

Optimizer4D Technical Specifications Installing Optimizer4D into a wall cabinet - horizontal In a first step, mount this metal plate to the wall and the lower on this page depicted metal plate to Optimizer4D. 69,2 If you insert a screw into the flap, it will serve as a fixation. - Page 20 Optimizer4D Technical Specifications Installing Optimizer4D into a wall cabinet - vertical 129,00 90,00 129,00 90,00 10,00 10,00 Angaben in Millim 1 : 1 Oberfläche: Härte: Maßstab: Angaben in Millimeter Schutzvermerk IS Toleranz: ISO 276 Generisch Schutzvermerk ISO 16016 beachten 1 : 1 Oberfläche:...

- Page 21 Optimizer4D Technical Specifications Wallmount characteristics Horizontal installation 258,38 224,00 17,4 Vertical installation 1 : 1 Härte: Angaben in Millimeter Oberfläche: Maßstab: Generisch Schutzvermerk ISO 16016 beachten Toleranz: ISO 2768 - Datum Name Nilges 07.06.2017 Gezeichn. Kontroll. Norm Zwischenblech-Waagerecht Rev.: Änderungen...

-

Page 22: Installing Optimizer4D Into Control Cabinet

Optimizer4D Technical Specifications Installing Optimizer4D to control cabinet 1. Prepare all parts. Refer to image 1 for overview. 2. Dismount wireway marked in image 2 („Vor dem Einschub demontieren“). Install Optimizer4D at control cabinet. Remount wireway. 3. Complete installation (image 3). -

Page 23: Casing Varieties

QASS Optimizer4D inside of a protective casing, signal lamp (optional) added. If you want to use Optimizer4D in a hazardous environment or at a manual mode machine, QASS recommends the protective casing which resists dust and mechanical impacts (including handle). An optional signal lamp shows if a work piece is good or faulty by a red or a green light. -

Page 24: Carrying Casing „Qase

Optimizer4D Technical Specifications Carrying casing „QASE“ QASE This is a transportable casing which is helpful if you want to use Optimizer4D at several locations or machines. QASE is made of durable plastics. Optimi- zer4D is securely installed into this casing and by this it‘s applicable for mobile and... -

Page 25: Memory Options

Memory options Optimizer4D writes measuring data in real-time to it‘s harddrives. While using highest data rate, Optimizer4D saves up to 25 MB / s to harddrive. This means 1,5 GB / min or 90 GB / h. 1 TB of memory will be full in roughly 11 hours. -

Page 26: Spare Parts

Weight (kg) Optimizer4D measuring device Optimizer4D O-OPTIMIZER4D 13,7 (control cabinet design) Wall bracket case for O-MC-Case-11-HW horizontal mounting Wall bracket Optimizer4D for O-MC-Case11-WHW horizontal mounting Wall bracket case for O-MC-Case11-HS vertical mounting Wall bracket Optimizer4D for O-MC-Case11-WHS vertical mounting Pre-amplifyer... - Page 27 Optimizer4D Technical Specifications Pos. Name Type Order-Nr. Weight (kg) Power supply 24 V, 150 W O-POWERSUPPLY 0,58 Uninterrupted power supply (UPS) Internal (Supercaps) O-USV 0,36 Screen 11,6 Inches O-TD 12 Please find the detailed Manual on www.qass.net/wp/support/downloads/?lang=en 27 / 27...

Need help?

Do you have a question about the Optimizer4D and is the answer not in the manual?

Questions and answers