Summary of Contents for TPE Di4000

- Page 1 INVERTER GENERATOR TPE Di 4 0 00 Open Frame Digital Inverter Generator 3500 Running Watts | 4000 Peak Watts...

-

Page 2: All Rights Reserved

This manual contains important instructions for operating this generator. For your safety and the safety of others, be sure to read this manual thoroughly before operating the generator. Failure to properly follow all instructions and precautions can cause you and others to be seriously hurt or killed. TPE TECHNICAL SPECIFICATIONS Gasoline Rated... -

Page 3: Safety Symbol Definitions

SAFETY SAFETY DEFINITIONS SAFETY SYMBOL DEFINITIONS The words DANGER, WARNING, CAUTION and NOTICE are used throughout this manual to highlight important information. Be certain that the meanings of these alerts are known to all who work on or near the equipment. -

Page 4: General Safety Rules

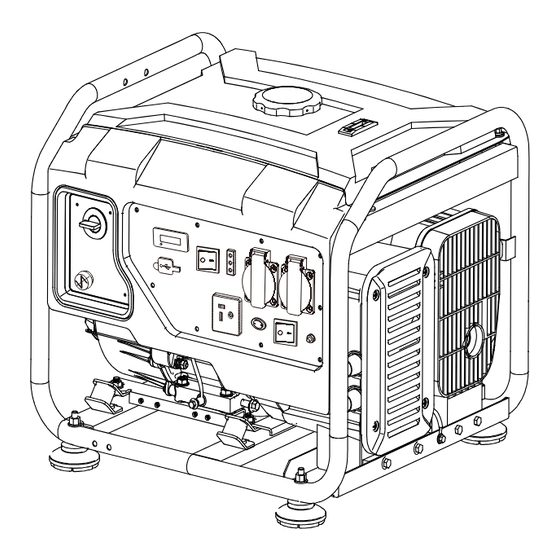

SAFETY GENERAL SAFETY RULES DANGER Never use the inverter in a location that is wet or damp. Never expose the inverter to rain, snow, water spray or standing water while in use. Protect the inverter from all hazardous weather conditions. Moisture or ice can cause a short circuit or other malfunction in the electrical circuit. - Page 5 FEATURES TPE Di4000 FEATURES Open frame inverter design: Quiet, fuel efficient power provided by a digital inverter built in a rugged open frame design. Choke lever: Pull to choke and push in to run once the engine has started. Oil Fill Plug/Dipstick: Must be removed to add and check oil.

-

Page 6: Control Panel Features

FEATURES CONTROL PANEL FEATURES Di4000 VFT Data Center: Press and release the mode Ground Terminal: The ground terminal is used to button to toggle between Voltage, Frequency, externally ground the inverter. Total Hour Meter and Run/Maintenance Timer. Voltage AC Switch: High standard swith to control the AC output. -

Page 7: Operation

OPERATION BEFORE STARTING THE INVERTER Weather – Never operate your inverter outdoors during rain, snow or any combination of weather conditions that could BEFORE STARTING THE lead to moisture collecting on, in or around the generator. INVERTER, REVIEW SAFETY SECTION. Dry Surface –... -

Page 8: Power Cord

OPERATION POWERCORD Using Extension Cords Full Boar Portable Power assumes no responsibility for the content within this table. The use of this table is the responsibility of the user only. This table is intended for reference only. The results produced by using this table are not guaranteed to be correct or applicable in all situations as the type and construction of cords are highly variable. -

Page 9: Adding/Checking Engine Fluids And Fuel

OPERATION ADDING/CHECKING ENGINE ADDING GASOLINE TO THE FUEL TANK FLUIDS AND FUEL WARNING BEFORE ADDING/CHECKING ENGINE FLUIDS AND FUEL, REVIEW SAFETY Never refuel the inverter while the engine SECTION. is running. DANGER Filling the fuel tank with gasoline while Always turn the engine off and allow the the inverter is running can cause inverter to cool before refueling. -

Page 10: Starting The Inverter

Pull out: Choke On Starting TPE Di4000 1. Move inverter to a flat surface outside in a well Figure 5: Pull choke lever ventilated area away from open doors or windows. -

Page 11: Stopping The Inverter

(see Figure 6) . 3. Press in the reset breaker to reset it (see Figure 7). Di4000 Figure 6: Push engine control switch to STOP position During an Emergency If there is an emergency and the inverter must be... -

Page 12: Maintenance

MAINTENANCE BEFORE PERFORMING MAINTENANCE ON THE INVERTER, REVIEW THE SAFETY SECTION, AS WELL AS THE FOLLOWING SAFETY MESSAGES. WARNING CAUTION Avoid accidentally starting the inverter Avoid skin contact with engine oil or during maintenance by removing gasoline. Prolonged skin contact with the spark plug boot from the spark engine oil or gasoline can be harmful. -

Page 13: Engine Oil Maintenance

MAINTENANCE ENGINE OIL MAINTENANCE If oil level is below this line it is too Engine Oil Specification low to operate. 1. Only use the engine oil specified in Figure 8. 2. Only use 4-stroke/cycle engine oil. NEVER USE 2-STROKE/CYCLE OIL. Synthetic oil is an acceptable substitute for conventional oil. -

Page 14: Changing Engine Oil

MAINTENANCE CHANGING ENGINE OIL AIR FILTER MAINTENANCE 1. Always operate or maintain the generator WARNING on a flat surface. Never use gasoline or other flammable 2. Stop the engine. solvents to clean the air filter. Use only household detergent soap to clean the air 3. -

Page 15: Draining The Float Bowl

MAINTENANCE Cleaning the Air Filter - Continued 2. Locate the clear plastic hose from the float that is exiting out the bottom of the inverter, and place a NOTICE suitable container under it to catch the drained fuel (see Figure 16). Never dispose of soap cleaning solution used to clean the air filter by dumping the solution into a sewer, on the ground, or into ground water or... -

Page 16: Spark Plug Maintenance

MAINTENANCE SPARK PLUG MAINTENANCE 8. Install the spark plug by carefully following the steps outlined below: The spark plug must be checked and cleaned after a. Carefully insert the spark plug back into the every 100 hours of use or 6 months and must be cylinder head. -

Page 17: Checking And Adjusting Valve Lash

MAINTENANCE Figure 20: Remove spark arrestor 8. Using a wire brush, remove any dirt and debris that may have collected on the spark arrestor screen. Figure 21 (1) valve , (2) Feeler Gauge Area 9. If the spark arrestor screen shows signs of wear (3) Rocker Arm, (4) Jam Nut, (5) Adjusting Nut (rips, tears or large openings in the screen), replace the spark arrestor screen. -

Page 18: Maintenance Reminders

MAINTENANCE NOTICE Gasoline stored for as little as 60 days can go bad, causing gum, varnish and corrosive buildup in fuel lines, fuel passages and the engine. This corrosive 00:00 buildup restricts the flow of fuel, preventing an engine from starting after a prolonged storage period. Proper care should be taken to prepare the inverter for MAINTENANCE REMINDERS any storage... -

Page 19: Troubleshooting

TROUBLESHOOTING WARNING Before attempting to service or troubleshoot the generator, the owner or service technician must first read the owner’s manual and understand and follow all safety instructions. Failure to follow all instructions may result in conditions that can lead to voiding of the EPA certification or product warranty, serious personal injury, property damage or even death. -

Page 20: Warranty Exclusions

• If the tool is disassembled or tampered with in any way. • The warranty excludes damage resulting from product misuse or product neglect. This warranty is given by TPE Australia Pty Ltd ABN: 98 116427 591 Ph: +614 56422515...

Need help?

Do you have a question about the Di4000 and is the answer not in the manual?

Questions and answers