Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for MAXX DIGM MAXX DS200 Series

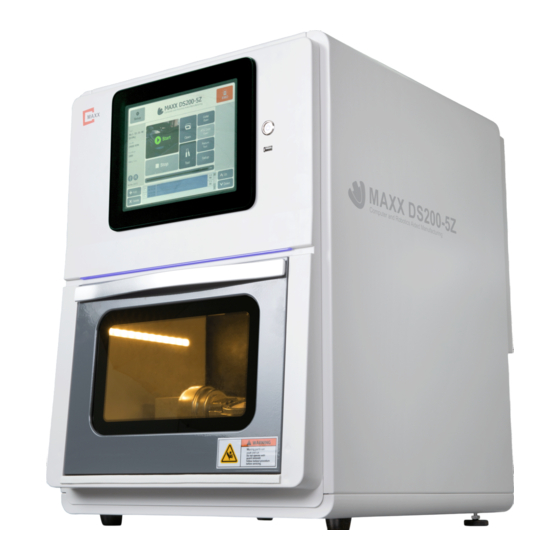

- Page 1 USER GUIDE MAXX DS200 series...

- Page 2 Computer and Robotics Aided Manufacturing Copyright © 2019 by Maxx Digm, Inc All rights reserved. This manual or parts thereof may not be reproduced in any form, stored in any retrieval system, or transmitted in any form by any means—electronic, mechanical, photocopy, recording, or otherwise—without prior written permission of the publisher, except...

-

Page 3: Table Of Contents

Computer and Robotics Aided Manufacturing Contents I. EPNC Installation ..............................5 Program Installation ............................5 II. Description of EPNC ............................6 2.1 Initialization window ........................... 6 2.2 Main window ..............................7 2.2.1 Functions of main window ......................... 7 2.3 Setup ................................14 2.3.1 Entering setup ............................. - Page 4 Computer and Robotics Aided Manufacturing 4.2.3 Cleaning mode ............................. 47 4.3 Periodic maintenance ..........................50 4.3.1 Replacing consumable parts ......................52 Spindle warm-up........................... 53 4.3.2 Spindle cleaning ..........................53 4.3.3 4.3.4 Auto Calibration ..........................54 4.3.5 Collet tightening ..........................71 V.

-

Page 5: Epnc Installation

Computer and Robotics Aided Manufacturing I. EPNC Installation Program Installation To install the program, copy PNC folder. PNC folder is organized as below. ① <Bin> Folder <Bin> contains necessary DLL files to execute Pnc.exe and the program. Below is the description of main executable file and DLL. File name Description Remarks... -

Page 6: Description Of Epnc

Computer and Robotics Aided Manufacturing II. Description of EPNC 2.1 Initialization window Initializing window is shown as below. The machine is initialized by pressing the “Home” button. Initial window of EPNC EPNC starts initializing when “HOME” is clicked. The window flashes for about 15 seconds while initializing. It stops initializing when “STOP”... -

Page 7: Main Window

Computer and Robotics Aided Manufacturing 2.2 Main window Once initialization is completed, main window will appear. Machine’s model is written on the top and commonly used functions are shown on the main window. 2.2.1 Functions of main window 2.2.1.1 Operational setting & EMO Function of setup and EMO is shown as below. - Page 8 Computer and Robotics Aided Manufacturing 2.2.1.2 Machine status It shows machine’s status and activated condition. Tool Number - Overall information of the clamped tool. - Indicating tool number and work hour [hour : minute : second]. Spindle RPM - Amount of spinning rounds per minute (Max: 60,000rpm). FeedRate (mm/min) - The rate at which the tool has moved at a constant operating cycle or time.

- Page 9 Computer and Robotics Aided Manufacturing 2.2.1.3 Commonly used functions Below is commonly used functions that are essential in operating the machine. Start - Initialize the selected NC file. - Once clicked, it changes to “PAUSE” and stops the milling process. - Can resume the milling process by pressing “PAUSE”...

- Page 10 Computer and Robotics Aided Manufacturing * Return Tool Returns the tool in the spindle collet to ATC * Settings Cleaning Mode DS200-5Z To clean floor of milling room. It is recommended to use with brush to dust inside of milling room.

- Page 11 Computer and Robotics Aided Manufacturing 2.2.1.4 NC File Displays information related to NC file and each functions are as shown below. ① Select file ② Milling start time / milling time ③ NC file name ④ NC file size ⑤ ▲: to show all the list of NC file ⑥...

- Page 12 Computer and Robotics Aided Manufacturing Unselect NC file Copy NC file from USB to embedded PC Quit Delete Check and click in the NC file list to delete the selected file Move NC file It is to change order of NC files. Click ③...

- Page 13 Computer and Robotics Aided Manufacturing ➔ If USB is not compatible with the machine, please change the USB format by following below instruction. ※ To format USB 1) Connect USB to a computer 2) Click on “my computer” 3) Right click on USB and click “Format (A)” 4) Click “File System”...

-

Page 14: Setup

Computer and Robotics Aided Manufacturing 2.3 Setup 2.3.1 Entering setup Set up mode is a function that sets the parameters required for a program to operate accurately and effectively. Click on the “set up” button in the main menu to display the password screen as shown below, allowing entry into three modes (each mode with different working permissions) 1) User P/W ->... - Page 15 Computer and Robotics Aided Manufacturing 2.3.2 Teaching 2.3.2.1 Functions of teaching ① ② ③ ① Coordinate and offset display. Coordinate offset, teaching point and option. ② Axis jog and jog shortcut button. ③ Opening and saving changed values. • Download to Controller – save changed coordinates to controller. •...

- Page 16 Computer and Robotics Aided Manufacturing 2.3.2.2 Coordinate offset & Teaching point The offset values of the coordinate system used by the equipment can be stored by axis, and the position of the various tools and system parameters can be saved. Coordinate Offset Displays coordinates for each position.

- Page 17 Computer and Robotics Aided Manufacturing Teaching Point Managing the registration of basic coordinates for each action of the equipment. Name Description Remarks Tool1-8 Position of tool 1-8 Ready Position Coordinates indicating preset position of spindle Coordinates for tool to move in fast speed to tool Tool Sensing Up sensor Tool Sensing Down...

- Page 18 Computer and Robotics Aided Manufacturing 2.3.2.3 Option To manage option data. Option Description Remarks Distance between probing sensor (tool length ZAxis Offset Origin adjustment sensor) and milling origin in millimeter. Tool Sensing High Speed High speed for tool sensing measurement Tool Sensing Low Speed Slow speed for tool sensing measurement Acceptable range in tool length before and after...

- Page 19 Computer and Robotics Aided Manufacturing 2.3.2.4 Jog Use the +/- buttons on each motor shaft to move the motor (stage movement) - Displays coordinates being used (coordinates based on motor) 0.000 - Indicates current coordinates of each axis + - (Symbol) - Indicating the directions for each axis - It is indicated as + + - changes into red when exceeding the limit.

- Page 20 Computer and Robotics Aided Manufacturing X±, Y±, Z± (Jog moving button) - To move stage in X, Y and Z axis direction. Check “Step”, “Cont.”, and “moving amount” before moving. A/B Axis Jog - To move A and B axis. G53~G54 - To select coordinates Spindle Clamp / Unclamp...

- Page 21 Computer and Robotics Aided Manufacturing Move XY. <Teaching Position> Select the location to move from the Teaching position and then click the “move XY” button on the bottom menu to move the X and Y axis to the selected position. To move X and Y axis to selected coordinates.

- Page 22 Computer and Robotics Aided Manufacturing 2.3.2.5 Auto Calibration (*Refer to 4.3.4 Auto Calibration) To perform an automatic measurement and calibration using the provided calibration disc. The process takes approximately 20 minutes.

-

Page 23: Tool

Computer and Robotics Aided Manufacturing 2.3.3 Tool A menu that provides general information about the tools and the time it has been used. The purpose is to manage tool usage. As shown above, it displays the maximum work time and current work time for each tool in “hour:minute:second”... - Page 24 Computer and Robotics Aided Manufacturing • Maximum usage of tool When maximum work time is set to be 100 and maximum usage to be 90, user will receive warning to change the tool after 90 hours. • Activating maximum usage function of tool “M710 Macro”...

-

Page 25: Term

Computer and Robotics Aided Manufacturing 2.3.4 Term To operate the machine with G-code and M-code. -

Page 26: Option

Computer and Robotics Aided Manufacturing 2.3.5 Option To customize the machine settings to user’s preference. Option Description Remarks To activate external buttons (DM110 series). Using. External Buttons and To stop the milling process when the door is Door Open Sensor open. - Page 27 Computer and Robotics Aided Manufacturing If the tool error occurred, Option Description Remarks Stop Stop Restart from tool changed Restart from tool replacing line before error line Restart From Beginning Restart from beginning Start next nc-file Start next NC file Require user’s confimration before restart of User confirmation file.

-

Page 28: I/O

Computer and Robotics Aided Manufacturing 2.3.6 I/O I/O (Input / Output unit) Input : “ v “ appears when sensor is detected. Output : “ v “ appears when there is port output. -

Page 29: Log

Computer and Robotics Aided Manufacturing 2.3.7 Log A file that stores all records of movement in the use of the equipment. Used to track and correct the cause of an error. Option Description Remarks Refresh Refresh log tlist Select All Select all list Unselect All Unselect all list... -

Page 30: System

Computer and Robotics Aided Manufacturing 2.3.8 System Check S/W updates and spindle drive times in addition to general settings for operation. S/W version Soft-Limit Limitation for each axis *Do not change without manufacturer’s confirmation Spindle Information Spindle operating time Change Controller I/P To change IP address of controller, I/O board and embedded PC and set Maxx Link port setting. -

Page 31: Milling

Computer and Robotics Aided Manufacturing III. Milling 3.1 Machine power Switch on the machines power switch at the back. 3.2 Milling preparation 3.2.1 Mounting workpiece 3.2.1.1 Disc type (98Φ, step type) Preparations Disc, disc cover, milling material (10~25T) ① Mount selected disc material on disc holder. ②... - Page 32 Computer and Robotics Aided Manufacturing 3.2.1.2 Pin type Preparations Glass ceramic holder (6 pin), material (pin type), Wrench set Mounting method ① Loosen the holder’s bolts (use 3Φ wrench). ② Check female and male of the material and insert it into the selected socket. ③...

- Page 33 Computer and Robotics Aided Manufacturing 3.2.1.3 Pre-milled bar (R & D type) D Type D-type does not require an extra jig. ① Insert the pre-milled bar in the selected socket position. Be sure to insert the pre- milled bar all the way into the socket. ②...

- Page 34 Computer and Robotics Aided Manufacturing R Type R Type requires a premade jig which matches its own pre-milled bar to offer an accurate milling quality and effectively reduce the need of post-polishing process. *Only use R-type jig supplied by RND ①...

-

Page 35: Tool

Computer and Robotics Aided Manufacturing 3.2.2 Tool Tool number and M-code is shown as below. Tool # M-Code M140 M141 M142 M143 M144 M145 M146 M147 <Precautions for manually installing the tool to the ATC> * Make sure that there is no tool being clamped inside the collet when you insert tool into the blank pocket of the ATC. - Page 36 Computer and Robotics Aided Manufacturing 3.2.2.1 Tool specification Please refer to tool specification for DS200 series as below. It is highly recommended to use tools provided from manufacturer otherwise milling quality cannot be guaranteed and spindle error/ tool broken error could occur. Milling Total Coating...

- Page 37 Computer and Robotics Aided Manufacturing RND Milling tool Naming Notation End Diameter End Radius Shank Diameter Blade Length Effective Length Total Length RU-Dia-R0.5x6x2.5x12x55S Material Coating Others RU: RND-Urethane - Diamond, DLC, TiN - Long, Short Version RM: RND-Metal - TiAIN, TiAIN + CrN, Non RP: RND-PMMA/WAX - EP (Electro Plating) RZ: RND-Zirconia...

- Page 38 Computer and Robotics Aided Manufacturing Category Shank Diameter Coating RND Tool Model Name Remarks RU-Dia- Φ6 Radius end mill/ring Φ10xL10 Diamond R3r1.5x6x29x25x55 Helix angle must be larger than Φ2 Diamond RZ-Dia-R1.0x6x4x20x55 25 degree. Restoration RZ-Dia- Φ1 Model Diamond Ball end mill R0.5x6x2.5x18x55L RU-Dia- Ball end mill, tapered step,...

- Page 39 Computer and Robotics Aided Manufacturing Φ2 Ball end mill, Ring Φ6xL4.5 RZ-Dia-R1.0x3x5x20x45 Φ1 Ball end mill, Ring Φ6xL4.5 RZ-Dia-R0.5x3x2.5x18x45 Φ0.6 Ball end mill, Ring Φ6xL4.5 RZ-Dia-R0.3x3x1.5x12x45 MMRB00302-3-RND(ring),Ring Φ0.3 RZ-Non-R0.15x3x1x2x45 Φ6xL4.5 RM-TiAlN- Flat end mill, for implant 3 Φ1.5F TiAlN R0.75r0.0x3x9x15x45 bar/abutment Helix angle must be larger than 25 Φ2...

- Page 40 Computer and Robotics Aided Manufacturing Φ2 RG-Dia-R1.0x6x14x50 Ball end mill Φ1 RG-Dia-R0.5r0.4x2.3°x6x14x50 Radius end mill, Tapered 2.3° Φ1 Ball end mill, Ring Φ6xL4.5 RG-Dia-R0.5x6x10x50 Φ0.6 Ball end mill, Ring Φ6xL4.5 RG-Dia-R0.3x3x6x50 GLASS Ball end mill, Ring Φ6xL4.5, For Φ2 RG-Dia-R1.0x3x14x40 test CERAMIC Radius end mill, Tapered 2.3°...

-

Page 41: Nc File

Computer and Robotics Aided Manufacturing 3.2.3 NC file * Refer to “USER GUIDE” [2. Description of EPNC] > [2.2.1.4 NC file] 3.2.4 Maxxlink Allows user to access and control the Embedded PC’s screen directly from the connected PC. Initialization ① Select the Maxxlink installation folder on your desktop ②... - Page 42 Computer and Robotics Aided Manufacturing There are four additional options at the bottom, other than the Embedded PC on the machine ① Disconnect Terminates the connection to the equipment. ② Transfer NC-File Transfers NC files to the equipment remotely. ③ Transfer Log Files Downloads log files from the equipment remotely.

- Page 43 Computer and Robotics Aided Manufacturing NC file upload (Transfer NC-File) Transfer NC-File: a pop-up window appears as shown above. Path : Hit “Start”. The Windows File Explorer appears to select the desired NC file. Once you have selected the NC files(s), continue to hit “Open” to start the file transfer. Please wait for the transfer to complete.

- Page 44 Computer and Robotics Aided Manufacturing Log file download (Transfer Log Files) *Menu path : Setup → Manager mode → Log Go to Log Page and select the log file(s) you want to download. Maxlink downloads only selected log file(s). (Date.log + Date.err file) Press the Transfer Log Files button to confirm the file name you want to download.

-

Page 45: Maintenance

Computer and Robotics Aided Manufacturing IV. Maintenance 4.1 Maintenance precautions <Caution> Be careful when handling the milling tool. The milling tool is sharp. Broken milling tool is dangerous. Use cautiously to avoid injury. ✓ This machine is a precise device. Perform daily management and maintenance. ✓... -

Page 46: Dummy Tool

Computer and Robotics Aided Manufacturing 4.2.2 Dummy tool Preserve the machine with dummy tool inserted. ✓ To prevent oil left in spindle collet from becoming solid ✓ To prevent particles from entering the spindle. Insert Dummy Tool How to insert dummy tool ①... -

Page 47: Cleaning Mode

Computer and Robotics Aided Manufacturing 4.2.3 Cleaning mode What is Cleaning Mode? This function provides easy time when cleaning milling waste trapped inside the processing room such as material chips and other foreign substance produced during the milling process. ① DS-4W series (Wet) Preparation before start Locate the removable connector on the right side of the processing room as show below. - Page 48 Computer and Robotics Aided Manufacturing After the tool is inserted, direct the connected hose towards the filter at the bottom of the processing room and press “Clean” on the main screen. (Above picture) Clean from top to bottom as shown above. *Never attempt to reach the crease curtain around the spindle.

- Page 49 Computer and Robotics Aided Manufacturing ② DS-5Z series (Dry) DS-5Z (Dry) models come with a cleaning port at the bottom of the processing room. To clean the dust, simply use brush to gather the dust to the cleaning port area and press “Clean”.

-

Page 50: Periodic Maintenance

Computer and Robotics Aided Manufacturing 4.3 Periodic maintenance Machine functions at its peak when being maintained regularly and carefully. Interval Scope of maintenance Daily Check the filling level of coolant tank Wipe out the processing room at the end of the working day Clean tool pocket Clean spindle collet Clean ATC holder... - Page 51 Computer and Robotics Aided Manufacturing *Cleaning processed sludge filter Dirty filter inside processing room (Left figure) - Remove the Metal tray (①) to remove the filter net(②). Shake off and wash away any remaining milling waste under running water. Liquid coolant tank filter net (Fright figure) - Turn ③...

-

Page 52: Replacing Consumable Parts

Computer and Robotics Aided Manufacturing 4.3.1 Replacing consumable parts Replacing tool pockets *Replace tool pocket when: ✓ Tilt occurs with tool inserted inside ✓ Tool pocket becomes loose ✓ Push Limit Error occurs frequently even though tool teaching is performed ①... -

Page 53: Spindle Warm-Up

Computer and Robotics Aided Manufacturing ③ Replace tool pocket and tighten it until it does not move. 4.3.2 Spindle warm-up Refer to 4.6 [Setup Guide] 4.3.3 Spindle cleaning Refer to 4.6 [Setup Guide]... -

Page 54: Auto Calibration

Computer and Robotics Aided Manufacturing 4.3.4 Auto Calibration Aim of calibration Process to match coordinates of milling machine and operation coordinates. Type of calibration Auto calibration Measure origin position using 98Φ Calibration Disk Multi Origin Auto Measure D-Type abutment coordinates (3) Teaching Measure R-Type abutment coordinates (3) ATC Auto teaching... - Page 55 Computer and Robotics Aided Manufacturing ① Installing calibration disc Check thickness of the calibration disc before installation and insert it to parameter ② Inserting calibration tool ATC Door Open: MAIN WINDOW > TOOL > ATC OPEN Open ATC from “Setup” then install at entered tool pocket position in parameter. ③...

- Page 56 Computer and Robotics Aided Manufacturing Check before start ✓ Disk Thickness: enter calibration disk thickness ✓ Tool_Diameter: enter calibration tool diameter ✓ Tool_Number: enter tool pocket number for calibration tool - The above values are already stored upon delivery *When input ①...

- Page 57 Computer and Robotics Aided Manufacturing ** DS-4W Series Connect the cable as shown above. When the contact between measuring magnet and the calibration disc is established. The icon “V” will appear indicating the presence of touch signal.

- Page 58 Computer and Robotics Aided Manufacturing Remove 3 and 4, select the desired axis of calibration as shown below and press start. Create a pop-up screen for execution and press “Start”. A window appears requesting confirmation. Description After holding a measurement tool and connecting cable, make a test Dummy measurement before making a real measurement.

- Page 59 Computer and Robotics Aided Manufacturing Select OK to confirm Check the correct cable connection and select connected ④ Once the Calibration completes ✓ Notification window appears upon completion. ✓ Press the Auto Calibration button to move the Coordinator offset screen ✓...

- Page 60 Computer and Robotics Aided Manufacturing ※ DS-5Z Basically, the 5Z calibration is almost identical to the (4W series) progress. Only, the connection method between the Calibration disc and the signal cable is slightly different. Keeps tools, measuring objects (discs, abutments, etc.) clean as they are electrically charged *Disk features of 5Z Isolated with special material on disk ₋...

- Page 61 Computer and Robotics Aided Manufacturing *To place disc for measurements Front (direction without grooves) – Disk surface Notch points at 12 o’clock Direction Rear (direction with grooves) – If the front is correctly positioned, the groove direction points to the 2 o’clock direction. ①...

- Page 62 Computer and Robotics Aided Manufacturing Description After holding a measurement tool and connecting cable, make a test Dummy measurement before making a real measurement. It reduces errors by settling the tool before doing the real measurement. A-axis Measure the Z-axis value of two horizontal points on the X-axis and horizontal calibrate the angle of the A-axis After rotating the A-axis, move the X-axis as much as the offset and...

- Page 63 Computer and Robotics Aided Manufacturing Select OK to confirm Check the correct cable connection and select connected ④ Once the Calibration completes ✓ Notification window appears upon completion. ✓ Press the Auto Calibration button to move the Coordinator offset screen ✓...

- Page 64 Computer and Robotics Aided Manufacturing 2. Multi Origin Auto Teaching (*DS200-4W / 4WA) Keeps tools, measuring objects (discs, abutments, etc.) clean as they are electrically charged <D-type> ① Mount D-type pre-milled bar *refer to [3.2.1.3 Pre-milled bar] ② Mount the calibration tool *refer to [4.3.4 Auto calibration] ③...

- Page 65 Computer and Robotics Aided Manufacturing Check before start ✓ D-type uses G57 [Multi] ✓ Check calibration position #1~#5 ✓ Tool_Diameter: enter calibration tool diameter ✓ Tool_Number: enter tool pocket number for calibration tool • Click on Name area and double click on value to enter desired value ✓...

- Page 66 Computer and Robotics Aided Manufacturing <R-type> ① Mount R-type pre-milled bar *refer to [3.2.1.3 Pre-milled bar] ② Mount calibration tool*refer to [Auto Calibration] ③ Prepare cable *2 for measurement (magnet+magnet 1, plug+magnet 1) ④ Auto Teaching: Setup > Multi Origin > Auto Teaching ⑤...

- Page 67 Computer and Robotics Aided Manufacturing 3. ATC Auto Teaching Keeps tools, measuring objects (discs, abutments, etc.) clean as they are electrically charged To automatically perform teaching of tool pocket X and Y coordinates. Setup > Teaching > Teaching Point > Auto Teaching ⚫...

- Page 68 Computer and Robotics Aided Manufacturing *For 5Z insert Tool Ring + Spindle collet until in contact *For 4W series, insert and leave approximately about 1cm apart of the tool shank E) Confirmation of the current flow...

- Page 69 Computer and Robotics Aided Manufacturing Plug + Magnetic Cable (①Plug ~ ②ATC Left Metal Panel) ₋ Magnet +Magnetic cable connection (③ATC left metal panel~ ₋ ④Calibration Tool) Test for the presence of Touch Signal (“V” icon appears) ₋ Remove 3 and 4. Continue to press “Start” ₋...

- Page 70 Computer and Robotics Aided Manufacturing ② Auto Teaching completion ✓ Notification message appears upon completion ✓ Hit “Back” to return to main window and Click Set-up → Teaching → Teaching Point ✓ Click Download to Controller & Save to file to save and change the value * Ensure that the tool can be held in the correct position after the Teaching is completed.

-

Page 71: Collet Tightening

Computer and Robotics Aided Manufacturing 4.3.5 Collet tightening The collet become loose eventually after each milling cycle causing the milling bur to fall out at some point. It is highly recommended to tighten the collet periodically. Interval Once a month, or when the total work time of the spindle exceeds 200 hours (with slight variation depending on the work situation) Procedure *refer to 4.2.2 Dummy Tool... -

Page 72: Trouble Shooting

Computer and Robotics Aided Manufacturing V. Trouble shooting 5.1 Restart milling How to restart the machine when it was stopped due to an error ① Stopped during milling ② After error reset, click “START” ③ A window requesting for restart method appears Start Line Selected NC-file Ex) 7 = 7th NC code line no. - Page 73 Computer and Robotics Aided Manufacturing For example) After milling Φ2, the machine successfully performed tool change from Φ2 to Φ1 but Φ1 break during milling and “tool broken” error occurs at the return of the tool. ☞ When you click on “from the selected line”, milling will restart from recent tool change line.

- Page 74 Computer and Robotics Aided Manufacturing...

-

Page 75: Air Pressure Sensor Setting

Computer and Robotics Aided Manufacturing 5.2 Air pressure sensor setting Please follow below instruction to pneumatic sensor. ① Press for 3 seconds. ② Press once. ③ Press three times. ④ Set value to 0.500 by pressing... - Page 76 Computer and Robotics Aided Manufacturing ⑤ Press once to move to next step. ⑥ Set value to 0.000 by pressing ⑦ Press twice to go back to ③. ⑧ Press for 3 seconds to go back to initial screen ①. *SMC –...

-

Page 77: Removing Atc Push Limit

Computer and Robotics Aided Manufacturing 5.3 Removing ATC push limit When performing Tool Get, an error can occur due to many reasons that makes spindle to push against the ATC. ① Close Error message ② Move spindle manual that is pushing ATC ** Move Z-axis (vertical direction of spindle) Setup >...

Need help?

Do you have a question about the MAXX DS200 Series and is the answer not in the manual?

Questions and answers