Subscribe to Our Youtube Channel

Summary of Contents for Tanco 580-J

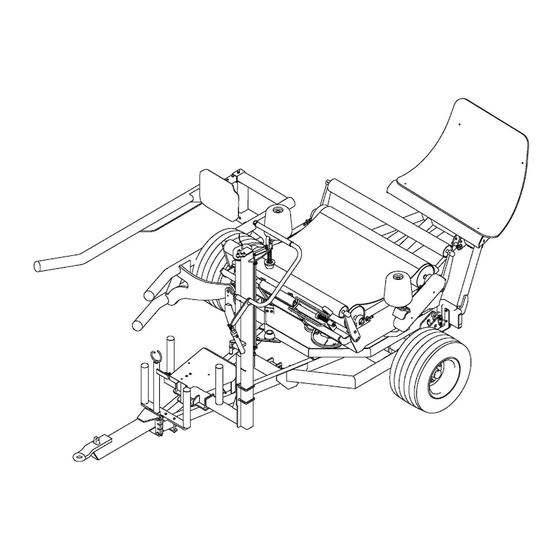

- Page 1 580-S/J OPERATOR’S HANDBOOK WD66-580S-M07011 Tanco Autowrap Ltd. Tel.: +353 (0)5997 21336 Royal Oak Road Fax: +353 (0)5997 21560 Bagenalstown E-Mail: info@tanco.ie Co. Carlow, Internet: www.tanco.ie Ireland...

- Page 2 Immediately, stop using the machine. A warranty claim form is available to download from our website: www.tanco.ie. This should be filled out and e-mailed to you Tanco distributor who will forward it Tanco for processing. Consult with your Tanco dealer (supplier) and have him forward your claim and the...

-

Page 3: Table Of Contents

Technical Specifications Pre-delivery instructions Transport Instructions Machine Identification Preparation of New Machine Electrical Circuit Diagrams 7.1 580-S Electrical Circuit Diagram 7.2 580-J Electrical Circuit Diagram Controller Manual Operating Instructions 580 J Joystick Operations Film overlap system Service & maintenance Technical Diagrams 12.1. -

Page 4: General Safety Recommendations

Tanco Autowrap 580-S/J Operator’s manual 1. GENERAL SAFETY RECOMMENDATIONS Before operating the machine, always ensure that the tractor and machine meet with work safety and road traffic regulations. Basic Principles 1. In addition to recommendations given in this manual, legislation on work safety and accident prevention must also be respected. - Page 5 Tanco Autowrap 580-S/J Operator’s manual 21. Do not stand between the tractor and the machine unless the hand break is tight and/or stops have been placed under the wheels. 22. Before any adjustments, maintenance or repairs are carried out, ensure that the machine cannot be started up accidentally.

- Page 6 8. Spare parts used must be in accordance with specifications and standards as defined by the manufacturer. Use only genuine TANCO parts. 9. Before any electric welding is carried out on tractor or attached machine, disconnect generator and battery terminals.

-

Page 7: Safety Instructions

Tanco Autowrap 580-S/J Operator’s manual 1.1. SPECIAL SAFTY INSTRUCTIONS 1. Stop engine of the tractor before working on machine. 2. Put a suitable prop under raised platform before working in this area. 3. Always raise lift Arm and fit safety prop before transporting machine on public roads. -

Page 8: Safety Decals

Tanco Autowrap 580-S/J Operator’s manual 1.2. SAFETY DECALS The following safety decals have been placed on your machine in the areas indicated. They are intended for your personal safety and for the safety of the other people working with you. With this manual. Walk around your machine and note the content and locations of these warning signs. -

Page 9: Technical Specifications

Tanco Autowrap 580-S/J Operator’s manual 2.TECHNICAL SPECIFICATION 580A/580S Dimensions Models Trailed Total length – Excluding Bale Ramp 350cm Width – excluding lift arm 221cm “ - lift arm fully raised 243cm “ - lift arm lowered 380cm Height to top of side (bale guide) rollers... -

Page 10: Pre-Delivery Instructions

Tanco Autowrap 580-S/J Operator’s manual 3. PRE-DELIVERY INSTRUCTIONS IMPORTANT: DO NOT ATTEMPT TO OPERATE THE MACHINE UNTIL THE FOLLOWING INSTRUCTIONS ARE PERFORMED. OTHERWISE SERIOUS DAMAGE COULD BE CAUSED. MACHINE ASSEMBLY For ease of transportation some items are removed from their positions and stored elsewhere on the machine. - Page 11 Tanco Autowrap 580-S/J Operator’s manual Attach bale ramp or mat to rear chassis. Note: Round bale trailed models have hydraulic bale ramps with an option of end tip bale ramp. Linkage mounted machines have bale mats. The standard 1080 trailed models have hydraulic bale ramps.

- Page 12 Tanco Autowrap 580-S/J Operator’s manual Instructions for fitting End-tip Ramp. The end-tip ramp is dispatched in standard tip (bale falling on it’s radial side) configuration. For end tipping move the pins on the top link so that is in the position shown in Fig 2.

- Page 13 Tanco Autowrap 580-S/J Operator’s manual - 13 -...

- Page 14 Tanco Autowrap 580-S/J Operator’s manual - 14 -...

- Page 15 Tanco Autowrap 580-S/J Operator’s manual - 15 -...

- Page 16 When all above assembly and checks have been carried out, the operation of the machine should be checked as follows: NOTE: IF YOU ARE NOT TOTALLY FAMILIAR WITH THE OPERATION OF THE TANCO CONTROL SYSTEM, READ THIS MANUAL IN FULL BEFORE PROCEEDING WITH OPERATIONAL TEST.

-

Page 17: Transport Instructions

Tanco Autowrap 580-S/J Operator’s manual 4. Transport Instruction 4.1 Never use straps around machine when lifting. Use only the following lifting points: - Tow hitch and two sockets on each side of Chassis at rear for trailed models. 3 pt. Linkage frame and two sockets on each side of Chassis frame at rear for 3 pt. -

Page 18: Electrical Circuit Diagrams

Tanco Autowrap 580-S/J Operator’s manual 7. Electrical Circuit Diagrams 580 S Electrical Circuit Diagram - 18 -... -

Page 19: 580-J Electrical Circuit Diagram

Tanco Autowrap 580-S/J Operator’s manual 580 J Electrical Circuit Diagram - 19 -... -

Page 20: Controller Manual

Tanco Autowrap 580-S/J Operator’s manual 8. Controller Manual 1 Introduction What can it do ? 2 The control switches 3 Using the instrument 3.1 Channel 1 - Current/Target Wraps display 3.1.1 Manually reset Current Wraps to zero – 5 3.1.2 Programme Target Wraps – 6 3.1.3 Programme Early Warning Alarm –... - Page 21 Tanco Autowrap 580-S/J Operator’s manual Introduction The instrument has 6 channel functions with an illuminated 4 digit LCD display, 5 switches to control all functions and an internal alarm. An external alarm is optional. The instrument is normally powered on via the vehicle ignition circuit and recalls the function displayed when the instrument was last used.

- Page 22 Tanco Autowrap 580-S/J Operator’s manual Channel 6 Bale Wrapping Speed Using the Instrument Channel 1 - Current/Target Wraps Display Press to select The left-hand section shows the current number of wraps and the right hand section shows the target number.

- Page 23 Tanco Autowrap 580-S/J Operator’s manual 3.1.2 Programme the Target Wraps Press to select Hold continuously. The third digit flashes. Hold to cycle to the required digit then release, otherwise press once… The fourth digit flashes. Hold to cycle to the required digit.

- Page 24 Tanco Autowrap 580-S/J Operator’s manual Channel 2 - Store Totals When bale wrap is complete, one of eight pre-selected memory store totals A, b, C, d, E, F, G, or H, is automatically advanced by 1. Store totals can be reset individually.

- Page 25 Tanco Autowrap 580-S/J Operator’s manual Channel 3 – Part Total When the bale wrap is complete, the part total is automatically advanced by 1. The part total can be reset at any time 3.3.1 Display Part Total Press to select Part total displays for 5 seconds then defaults to channel 1.

- Page 26 Tanco Autowrap 580-S/J Operator’s manual 3.5.2 Reset Timing Period Press to select Press and hold for 5 seconds. Channel 6 - Bale Wrapping Speed Displays instantaneous r.p.m. of the bale wrapper at 3 second intervals in the range 10-99 r.p.m. An overspeed alarm will sound if the r.p.m.

- Page 27 Tanco Autowrap 580-S/J Operator’s manual Film Break Alarm Only operational where optional film break sensor is installed (see parts book). If the film should break, after 1 second the display will show “STOP”, the alarm will sound and the turntable stops.

-

Page 28: Operating Instructions

Tanco Autowrap 580-S/J Operator’s manual 9. OPERATING INSTRUCTIONS 9.1 Fitting roll of film. When loading a plastic roll, first ensure the top cone (2) is pushed up to latched position, then push back the Stretch rollers (3) until held in position by locking catch (4). . - Page 29 Therefore, any use of the lift arm outside its primary function will be deemed to be abuse and will void all warrenty. TANCO DUAL STRETCH FILM DISPENSER Some Tanco Autowrap machines can optionally be fitted with a patented dual stretch gear system. This system enables a quick change of stretch levels on the Film Dispenser.

-

Page 30: 580 J Joystick Operations

Tanco Autowrap 580-S/J Operator’s manual 580 J JOYSTICK OPERATIONS - 30 -... -

Page 31: Film Overlap System

Tanco Autowrap 580-S/J Operator’s manual 10. Film, Overlap System The Autowrap is fitted as standard with the 2 x 2 x 50% film overlap system. This is achieved by means of a chain drive which ensure that the correct number of film layers are applied to the bale after a specific number of revolutions of the turntable. The number of revolutions required to wrap a bale depends on width of film being used and bale size –... -

Page 32: Service & Maintenance

Tanco Autowrap 580-S/J Operator’s manual 11. Service and Maintenance All nuts and bolts should be tightened after the first hour’s use, thereafter regulary. Wheel pressure should be normally kept at 42 psi depending on bale weight and field conditions. Inspection moving parts for wear on daily basis. - Page 33 Tanco Autowrap 580-S/J Operator’s manual Shear Pins There are two shear pins fitted to sprocket assembly on drive roller see fig. 5. If the pins shear, remove the broken pins re- aligin holes and fit two replacement spiral pins, 6mm dia x20mm long, Din 7344. There are two spare shear pins attached to inside of chain guard.

-

Page 34: Technical Diagrams

Tanco Autowrap 580-S/J Operator’s manual 12. Technical Diagrams 12.1. Film Threading Diagram - 34 -... -

Page 35: Gear Box Chain Drive Tensioning System

Tanco Autowrap 580-S/J Operator’s manual 12.2. Gear Box Chain drive tensioning system - 35 -... -

Page 36: Turntable Chain Drive Tensioning System

Tanco Autowrap 580-S/J Operator’s manual 12.3. Turntable Chain Drive tensioning system - 36 -... -

Page 37: Bale Ramp Cylinder-Recharging Instruction

Tanco Autowrap 580-S/J Operator’s manual 12.4. Bale Ramp Cylinder - recharging instruction - 37 -... -

Page 38: Cut & Start Cylinder - Recharging Cylinder

Tanco Autowrap 580-S/J Operator’s manual 12.5. Cut & Start Cylinder – Recharging cylinder - 38 -... -

Page 39: 580-S Hydraulic Circuit

Tanco Autowrap 580-S/J Operator’s manual 13. Hydraulic Circuits 13.1 580-S Hydraulic Circuit - 39 -... -

Page 40: 580J Schematic Hydraulic Circuit

Tanco Autowrap 580-S/J Operator’s manual 13.2 580J Schematic Hydraulic Circuit - 40 -... -

Page 41: Closed Centre Conversion

Tanco Autowrap 580-S/J Operator’s manual 14. OPEN / CLOSED CENTRE CONVERSION Most tractors are fitted with Open Centered Hydraulic systems. For this reason, our valves are set-up as standard for open centers. However some tractors (e.g. John Deere) use closed centered systems. Consult your dealer if you are unsure about your system requirements. -

Page 42: Fault Finding

Tanco Autowrap 580-S/J Operator’s manual 15. FAULT FINDING (ROUND BALE MODELS) PROBLEMS REMEDY Driver roller and Bale belt not driving. Check if shear pins have sheared in sprocket on drive roller if so, Replace. Film not wrapping evenly Adjust the film mast, so that centre of film roll is in-line with... - Page 43 Tanco Autowrap 580-S/J Operator’s manual THIS IS VERY IMPORTANT Make sure you have a good connection on the battery both positive and negative BALE MOVEMENT ON MACHINES Ensure enrollers (black cone plastic) are in tight to bale, the bale will reduce in size during wrapping, the...

-

Page 44: Declaration Of Conformity

Tanco Autowrap 580-S/J Operator’s manual 16. EU DECLARATION OF CONFORMITY ACCORDING TO DIRECTIVES 89/392/336/EEC AS AMENDED Manufacture: TANCO ENGINEERING CO LTD BAGENALSTOWN CO CARLOW IRELAND CERTFIES THAT THE FOLLOWING PRODUCT: AUTOWRAP MODEL: 580-S SERIAL NO.: D10-000 - To which this declaration relates, corresponds to essential requirements of the Directive 89/392/336/EEC as amended.

Need help?

Do you have a question about the 580-J and is the answer not in the manual?

Questions and answers