Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for herdstar BINTRaC BT200

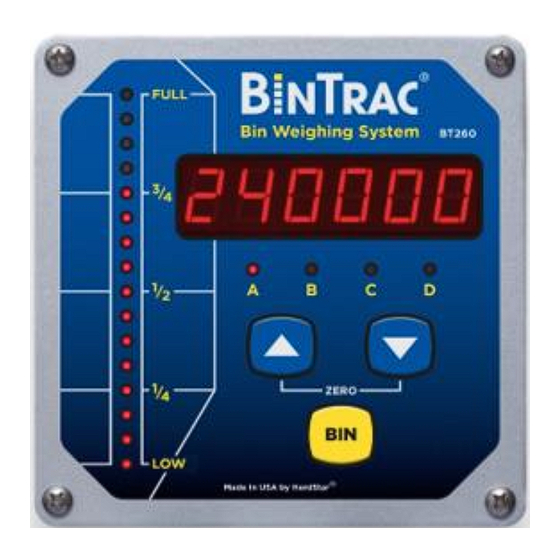

- Page 1 Operation Manual Bin Weighing System Operation Manual BT200/BT260 U.S. Patent No. 7,980,129, Patent No. 8,581,122, Patent No. 8,853,566 U.S. Patent No. 9,310,243, Patent No. 9,651,413, Patent No. 10,082,421 Canada Patent No. 2,822,294 Korea Patent No. 1900521 BT200 BT260 07/12/2019...

-

Page 2: Table Of Contents

HerdStar BinTrac Warranty............................. 19 EU Declaration of Conformity (CE) ..........................20 is a trademark of HerdStar, LLC. Copyright © 2011 HerdStar, LLC. All rights reserved. Printed in the USA 1400 Madison Avenue Suite 504, Mankato, MN 56001 PH: 507-344-8005 FAX: 507-344-8009 www.herdstar.com... -

Page 3: Overview

Operation Manual Thank you for purchasing a BinTrac bin scale system from HerdStar, LLC. Overview Your BinTrac bin weighing system provides a cost-effective way to automatically monitor bin levels, facilitating just-in- time deliveries and minimizing out-of-material events that impact production performance. -

Page 4: System Setup

Operation Manual System Setup The units are easily wired by a qualified technician using standard communication wiring. See the BinTrac Installation Manual for detailed wiring information. The System setup has two levels of settings: 1) Operation Settings: These are settings that may be changed for normal use by an operator and 2) System Settings: These are a one-time setup usually done at the time of installation. -

Page 5: Program Alert Level

Operation Manual Program Alert Level (Optional alert relay assembly feature on the BT260) This procedure adjusts the level that the output (alert) relay is triggered. The output relay has both normally open and normally closed contacts. 1. Press and hold the LOWER key for 5 seconds. -

Page 6: System Settings

Operation Manual System Settings The SETUP mode is used to configure the one-time system setup settings for each bin. If there is no activity for five minutes while in the SETUP mode, the system will exit SETUP mode and return to auto sequence mode. Accessing the SETUP mode 1. -

Page 7: Setup (Version 3.0 And Higher)

Operation Manual Setup (Version 3.0 and higher) The Bin LEDs indicate configuration options as being enabled (solid on) or disabled (flashing). If not using any of the below options, ensure that all bins are showing as disabled (flashing) when is shown on the display. Bin A –... -

Page 8: Setup Mode Settings

Segmented display: Rated Value The average rated output in millivolt/volt (mV/V) of the load cells. If using load cells other than the HerdStar load cells, you may need adjust this value appropriately. *IMPORTANT – DO NOT change this setting from the default of 3.000 if you are using HerdStar load cells. - Page 9 Operation Manual Increment Value (incr) incr Display Sets the increment that the bin weight will be rounded to. The reading from a bin 11314 is rounded to the nearest multiple of the increment, using standard rounding rules. The possible values are: 1, 2, 5, 10, 20, 50, 100, 200, 500, 1., 2.,5.,10.,20., and 50.. 11314 11315 Example: If an increment of 10 is selected and the net value of a bin’s weight is...

- Page 10 Operation Manual Station ID Value Sets the Station ID of the device. When interfacing the device to a Communication Hub (CH100), set this value between from 1 to 127. Each BinTrac device must have a unique Station ID. 1. Press the BIN key to select the desired Bin. 2.

-

Page 11: Internal Mode

Operation Manual Internal Mode Any changes made to the internal settings may adversely affect how the BinTrac system operates. DO NOT make changes to any items without understanding the affect it may have on the operation of the BinTrac System. Accessing the Internal mode 1. -

Page 12: Internal Mode Settings

Operation Manual Internal Mode Settings Gain GAIN is a calculated field that should NOT be changed by the user. Segmented display: Serial Number The serial number is preset during production and should NOT be changed by the user. Segmented display: Pulse Value Sets the number of weight units per pulse when used in conjunction with a HouseLink Digital Interface (HL-10D). - Page 13 Operation Manual Baud Value Used to configure the serial communications baud rate. The options are 1200, 4800, 9600, 19200, 38400, 57600. The default is set to 57600. 1. Press the BIN key 2. Use the UPPER key and LOWER key to cycle to the desired value. Segmented display: Test An internally used feature that puts the Indicator through a series of LED tests.

-

Page 14: Operation

Operation Manual Operation Select Bin for Display Press the BIN key to cycle through the enabled bins. The bin weight and level for the selected bin will be displayed for twenty seconds. After this delay, BinTrac will return to the auto sequence mode described below. Auto Sequence Mode Five minutes after last keystroke unit begins auto sequence mode, starting from the last displayed bin. -

Page 15: Service

2. Check the Indicator settings Incorrect weight readings when the system is otherwise functioning normally can be due to incorrect settings. a. Confirm Rated Output – should match the average output recorded on each load cell (3.000 for HerdStar- supplied load cells) b. - Page 16 Operation Manual 3. Inspect the Smart Summing Box Small fluctuations in weight can be caused by a problem with the Smart Summing Box. a. Inspect for moisture and/or foreign material. b. Inspect for loose wires and connections. 4. Inspect Load Cells Wild fluctuating weights, a weight that does not change, a negative weight reading, or “Error”...

- Page 17 Operation Manual This means that the weight in the bin has exceeded the programmed system capacity by 150% and the system is in an over-load state. 1. Verify programmed settings are correct 2. Check for physical binding of brackets/hardware 4. Remove the weight from the system and check the condition of each load cell (See Load Cell Troubleshooting Procedures) This means that the Remote Display has lost communications with the host BinTrac Indicator.

-

Page 18: Load Cell Troubleshooting Procedures

Operation Manual Load Cell Troubleshooting Procedures The procedures below outline the steps for identifying and locating a defective load cell. Procedure 1 is most commonly used and quickest, although Procedure 2 can be used for better analysis and for determining even loading across all load cells. -

Page 19: Herdstar Bintrac Warranty

12 months or the term of any extended warranty. In the event of a defect in any Products constituting a breach of the warranty provided herein, HerdStar, LLC will at its option either (i) repair or replace such Product free of charge, or (ii) in lieu of repair or replacement, refund to Buyer the original purchase price less the reasonable value of Buyer’s use of the Products. -

Page 20: Eu Declaration Of Conformity (Ce)

EN 61000-3-2 EN 61000-3-3 EN 61000-6-1 EN 61000-6-3 ROHS EN 5081:2012 Signed for on behalf of HerdStar, LLC at 1400 Madison Avenue Suite 304, Mankato, MN 56001 USA 11/30/2018 Mark Jaeger President BinTrac Operator’s Manual Ver. 3.18 Rev. 1.01 Part Number MAN-000004-2...

Need help?

Do you have a question about the BINTRaC BT200 and is the answer not in the manual?

Questions and answers