Summary of Contents for Etac HIFLEX NEO

- Page 1 Temperature and Humidity Test Chamber Main body / Maintenance T e m p e r a t u r e ( H u m i d i t y ) C h a m b e r Operation Manual Issued on oct.29, 2012 (5th edition)

- Page 2 Preface Thank you very much for purchasing our HIFLEX NEO series Temperature (Humidity) This NEO series was developed utilizing ETAC's original Chamber. technologies and taking the current market trends into consideration. We believe that this series will meet your various needs. In order to use all...

-

Page 3: Table Of Contents

INDEX ■ F ........................6 ● O ......................6 ARNING ABELS ● P ..........7 LEASE OBSERVE THE FOLLOWING INSTRUCTIONS FOR SAFETY ■ I ....................11 MPORTANT NSTRUCTIONS ● I ....................11 NSTALLATION NVIRONMENT ● P ................14 RECAUTIONS FOR HANDLING SPECIMENS ● H .................... - Page 4 ● W ....................43 IS DISPLAYED ● W ....................45 IS DISPLAYED ● W 11, 12, .................. 48 IS DISPLAYED ● W ..................49 IS DISPLAYED ● W ..................50 IS DISPLAYED ● W 21, 22, .................. 51 IS DISPLAYED ●...

- Page 5 ◇ T ................81 HE EARTH LEAKAGE BREAKER TRIPPED ■ M ................... 83 AINTENANCE AND NSPECTION ○ C ................83 HECK POINTS FOR ST MONTH INSPECTION ○ C ................84 HECK POINTS FOR RD MONTH INSPECTION ○ C ................85 HECK POINTS FOR TH MONTH INSPECTION ○...

-

Page 6: For Safe Use

■ For Safe Use Although safety features are incorporated in our product designs, inappropriate usage by users may cause fire, electric shock, etc., which can result in physical injury. When using a chamber, please first read this operation manual carefully to ensure correct and safe operations. -

Page 7: Please Observe The Following Instructions For Safety

● Please observe the following instructions for safety Category Source of danger CAUTION Possible harm Caution Otherwise, an electrical shock, Do not use a power source of other than Power source heat, or fire may be caused. 50/60Hz frequency. Frequency Caution Insert the power plug completely. - Page 8 Category Source of danger CAUTION Possible harm Warning Do not use the power plug if the This may cause an electrical Power plug connection is loose. shock, short circuit, or heat. Connection Category Source of danger CAUTION Possible harm When not using the chamber for a Caution Power plug long time, disconnect the plug to...

- Page 9 Category Source of danger CAUTION Possible harm Caution Select a floor which can properly The chamber may fall causing Installation site withstand the weight of the chamber. injury or damage. Floor load Caution The chamber may fall causing Installation site Install the chamber on a level floor.

- Page 10 Category Source of danger CAUTION Possible harm Warning Service engineers or vendors only. Disassembling and Otherwise, an electrical shock, Unauthorized personnel are strictly Disassembling alternation heat, or fire may be caused. prohibited. and alteration (When Transferring) Category Source of danger CAUTION Possible harm Warning...

-

Page 11: Important Instructions

■ Important Instructions ● Installation Environment Environmental test chambers are precision apparatuses. In order to maintain reliable performance for the long term, please prepare a suitable installation environment by observing the following instructions. 〇 Maintain the room temperature of the installation site within the range of +10℃ to 32℃. - Page 12 〇 Do not use the chamber in a corrosive or explosive atmosphere. This may cause breakdown, malfunction, or deterioration. Also, this may cause accidental explosions. This device does not have explosion-proof construction. 〇 Do not place the chamber near equipment that may cause noise. This may cause breakdown, malfunction, or control failure.

- Page 13 〇 Chamber installation space For air suction/exhaust of the refrigerator and for opening/closing the door, the following space needs to be secured. Minimum space required for normal usage ◇ Refrigerator exhaust heat 100 or more outlet Earth leakage breaker, external output terminals, LAN cables are connected on this side...

-

Page 14: Precautions For Handling Specimens

If it is not possible * In order to perform maintenance work, minimum space of 600mm is required. to move the chamber forward, please make sure to secure the said space. - Caution - 1. Please consult us for required installation space if optional items such as cable port are added. 2. - Page 15 Countermeasures 3 Try not to open the door while a low temperature test is being performed (below dew-point temperature) so that specimens are not exposed to open air. Under this circumstance, if the door is opened [Example] When the environment is 23 ℃/65%RH, the dew-point temperature is 16 ℃. when the temperature inside the chamber is below 16℃, the internal surface of the chamber and specimens will condensate.

-

Page 16: Handling Instructions

● Handling Instructions ○ Do not repeatedly turn on and off the power switch of the main body. Excessive turning on/off of the switch during an operation may cause failure of the device. ○ In order to protect specimens, be sure to set the overheat protector. If the setting is not performed, an operation will not stop even if the temperature inside the chamber is abnormal until it exceeds 110℃... - Page 17 Schedule 1 [Extracted from “Industrial Safety and Health Law, Enforcement Order Article 6, Attached Table”] ○ Explosive Substances ① Nitroglycol, nitroglycerine, nitrocellulose, and other explosive nitrate esters. ② Trinitrobenzene, trinitrotoluene, picric acid, and other explosive nitro compounds ③ Peracetic acid, methyl ethyl ketone peroxide, benzoyl peroxide, and other organic peroxides ④...

-

Page 18: Operating Instructions

● Operating Instructions ○ Instantaneous voltage drop When voltage of the main power suddenly drops due to a lightning, etc., the connected PC may be affected. In order to avoid such a circumstance, it is advisable to use a UPS for your PC. ○... - Page 19 ○ Countermeasures to prevent overheating and overcooling while temperature is increasing and decreasing If the shortest temperature ramp-up or ramp-down time is set during a program operation, temperature will increase or decrease with the maximum capacity to reach the target temperature. Therefore, there is a possibility of overshooting or undershooting the target This problem can be prevented by setting the ramp-up or temperature by about 1 to 2℃...

-

Page 20: Precautions For Disposal

● Precautions for disposal (recovery and decomposition of fluorocarbon refrigerant) The fluorocarbon refrigerant used in the refrigeration circuit of this chamber must be recovered and decomposed according to the Fluorocarbons Recovery and Destruction Act (a law which stipulates the collection and the decomposition of fluorocarbons used in certain products). In order to control discharge of fluorocarbons into the atmosphere through proper recovery and destruction, it is prohibited to discharge three types of fluorocarbons;... - Page 21 Water tank Shelf board Shelf board bracket Operation Manual (Digest version)...

-

Page 22: Name Of Parts

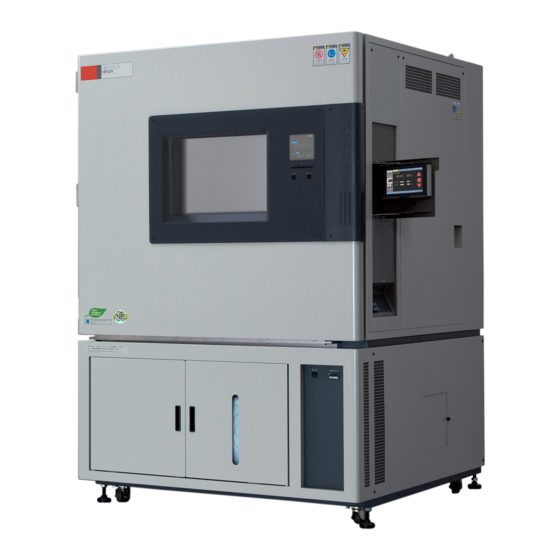

■ Name of Parts Temperature (humidity) controller (Local controller) Exhaust vent Power cable port Service panel Door: Earth leakage breaker Viewing window Drainage outlet 1 Drainage outlet 2 Water tank Adjuster Caster Subtank Cable port Overheat protector External Output (For protection of specimens) Terminal AC100V 3A Air inlet... -

Page 23: Preparing For Operation

■ Preparing for Operation 1. Installing the chamber ① Use a level or another instrument to check if the internal floor inside the chamber is on the level, and if not, adjust the levelness using adjusters mounted on each leg of the main body. ②... -

Page 24: Connecting Drain Hoses

3. Connecting drain hoses Tightly connect two drain hoses. Functions of drain hose 1 and drain hose 2 are as follows. For drainage, prepare an around 10-liter container to receive discharge water and throw it away periodically, or connect a drain pipe (recommended). - Caution - When using a tap water direct feed system or purifier direct feed system (optional), be sure to firmly connect both drain hose 1 and drain hose 2 to the drain pipe, and do not use the drain pan. -

Page 25: Connecting The Power

4. Connecting the power The power source specification of this chamber is AC200V ± 10%, 3-phase, 50/60Hz. Remove the service panel on the right side and firmly connect the specified cable in the table below with the earth leakage breaker. Power c cable port ①... -

Page 26: Starting An Operation

5. Starting an operation ① Open the door and attach a wick gauze to the sensor (not required for FL type). ② Turn on the earth leakage breaker (on the side of the main body) and the power switch at the front of the main body in order. ③... -

Page 27: Additional Functions

■ Additional Functions ● Interlock If specimens are electric / electronic components (transformer, capacitor, resistance, mounting board, etc.) and they need to be energized, be sure to use interlock terminals. If any abnormalities occur within the chamber, relay contacts are activated and electric conduction is automatically stopped in order to prevent an increase of temperature inside the chamber due to heat generation from specimens (* please refer to the figure below for connection method). -

Page 28: External Output Terminal

● External Output Terminal Table 2: External output terminals and their contact capacity Name Description Contact capacity During a humidity test, etc., a contact signal is Time signal output output for each step. terminal This can be used for starting DC power (Time signal)... -

Page 29: Lan Connector

● Plug socket When using this as a power source for specimens, use with the interlock A plug socket is provided for an external terminal (PC). terminal. - Caution - When using this as a power source for In principle, please use the provided plug socket for an external terminal (PC). specimens, be sure to use with the interlock terminal. -

Page 30: Humidification Vapor Recovery System

● Humidification vapor recovery system The FX type comes with the humidification vapor recovery system as a standard specification. A part of vapor is condensed, collected, and reused by this system. In particular, this system is effective for high temperature/humidity operations with high vapor pressure (60℃, 80% or higher). (See Table A) Table A Examples of water consumption at 85℃, 85%RH operation Model Minimum humidification water... -

Page 31: Operating Functions

■ Operating Functions ● Local/remote control operation Each method is called local control and remote control There are two ways to operate the chamber by using the control panel or a browser. respectively. As for local control, constant operation can be configured other than running and stopping a test. As for remote control, a chamber can be operated using a browser of a network terminal (PC or tablet PC) which is connected with a LAN cable, In addition to program configuration including multiple steps, various functions such as user management, operation control, etc. - Page 32 ◇ When an operation is started using the remote controller During a remote control operation, the local controller cannot be used to start a test or change settings of the program which was configured using the remote controller. START START Pause Pause Chang Set...

- Page 33 Restarting a remote control operation after being paused by using the remote controller ◇ In order to restart a remote control operation after being stopped by using the remote controller, the remote controller must be used. The operation cannot be resumed with the local controller. Restart Pause ①...

-

Page 34: Displaying The Status Of Equipment/Instrument

● Displaying the status of equipment/instrument Status of equipment/instrument can be checked during an operation using the local controller. For details, please refer to the table below. To change display By pressing the Λ key, current value of items different items can be viewed one by one starting from STEP. - Page 35 (d1) REF 2 EVAPORATING Indicates the current REF2 evaporating temperature. * -44.9 TEMP Example: REF2 evaporating temperature is ℃. (E2) *1 REF 2 SUCTION TEMP Indicates the current REF2 suction temperature. (S2) -23.6 Example: REF2 evaporating temperature is ℃. *1 REF 2 DISCHARGE Indicates the current REF2 discharge temperature.

-

Page 36: Error Numbers

■ Protective Device ● Error numbers When any abnormality occurs during an operation, the error (Er) number as shown in the list below will be displayed in the temperature/humidity display area of the local controller while an alarm sounds, and then the operation will be stopped. Be sure to take necessary measures to solve the problem according to the causes of the error before resuming an operation. - Page 37 Display Description Detector Subtank's water level increased excessively. Float switch Er27 Primary power source's phase does not match. Negative phase relay Er31 The refrigerator protector for refrigerator 1 inverter was Protection circuit inside the Er32 activated. inverter Refrigerator 1 is overheated. Pipe temperature sensor, or (Discharge temperature or compressor head temperature Er41...

- Page 38 ● Alarm numbers When any abnormality occurs during an operation, the alarm (AL) number as shown in the list below is displayed in the temperature display area Although an operation will be continued for alarms other than AL84, necessary measures of the chamber while a buzzer sounds.

-

Page 39: About Setting Of Upper And Lower Temperature Limits

● About setting of upper and lower temperature limits In order to protect specimens, upper and lower temperature (humidity) limits are set in relation to the set temperature. Once upper and lower temperature (humidity) limits are set, an upper and lower temperature (humidity) limit zone is created, and either one of the following actions can be selected against operating temperature deviation from the temperature zone. -

Page 40: How To Reset Error/Alarm

■ How to Reset Error/Alarm ● Error/alarm resetting procedures In order to stop alarm or buzzer, Stop the sound. Press the > key. ① While pressing the > key, Reset the error. ② press the SET key. If the sound continuously generates, it means that ... -

Page 41: Defrosting Method

■ Defrosting Method ● About frost formation on the chiller In order to maintain the temperature/humidity, a chiller (evaporator) is placed inside the chamber. This chiller consists of numerous aluminum boards which are overlapped in a several millimeter pitch, and its surface temperature is very low (-45℃ to 0℃) when the temperature Because air inside the chamber repeatedly passes through these aluminum boards, inside the chamber is between -40℃... -

Page 42: When Er01 Is Displayed

■ Troubleshooting If any problem occurs relating to this product, please first read the following error/alarm information before contacting us or your vendor. Whenever error occurs, various information such as time, temperature/humidity, and operational status (temperature measurements of various parts of the refrigerators, ambient temperature, control output values) will be automatically stored in the main body memory. -

Page 43: When Er04 Is Displayed

b) SSR (solid state relay) for the thermal heater control is short-circuited and the thermal heater is continuously turned on. c) Deterioration of cooling capacity. d) Localized overheating caused by decrease in circulation air velocity. [Inspection procedure] 1) Reset the error. 2) Remove specimens from the chamber. - Page 44 ● LEVEL ADJUST FLOAT FAULTY or LEVEL ADJUST ERROR Humidification water level is detected by the float switch inside the level controller that can be found inside the Water level cannot be correctly detected if the main body is terribly tilted service panel on the right side.

-

Page 45: When Er06 Is Displayed

● When Er06 is displayed Error / alarm No., and messages Local Possible causes and diagnosis * In the case of the controlle Functions to be remote controller, clicking the number will indicate Messages appear in the remote activated the causes and remedies. controller's browser display OCP SET ERROR... - Page 46 ● When Er07 or 08 is displayed Error / alarm No., and messages Local Possible causes and diagnosis * In the case of the Functions to be controller remote controller, clicking the number will indicate Messages appear in the remote activated the causes and remedies.

- Page 47 =>① Evaporating temperature does not fall below -15℃ when temperature decreases. ② Evaporating temperature does not increase from -48℃ when temperature decreases. ③ Temperature inside the chamber does not reach -40℃, or temperature ramp-down rate obviously became slower. (For temperature ramp-down rate when inside the chamber is empty and ambient temperature is 18 to 28℃, please refer to the specification tables in P95 to P102.

-

Page 48: When Er11, 12, Or 13 Is Displayed

● When Er11, 12, or 13 is displayed Error / alarm No., and messages Local Possible causes and diagnosis * In the case of the Functions to be Messages appear in the controller remote controller, clicking the number will indicate the activated remote controller's causes and remedies. -

Page 49: When Er15 Or 16 Is Displayed

4) Press the > key to continuously display the discharge temperature on the local controller. (For more details about display, please refer to “P34 Displaying the status of equipment /instrument”.) ⇒ If there are no problems in terms of suction and exhaust of air and yet discharge temperature exceeds 100℃, please stop the operation because comprehensive inspection for the refrigeration circuit is necessary.. -

Page 50: When Er18 Or 19 Is Displayed

● When Er18 or 19 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the Functions to be remote controller, clicking the number will indicate the Local controller Messages appear in the activated causes and remedies. -

Page 51: When Er21, 22, Or 23 Is Displayed

● When Er21, 22, or 23 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Functions to be Local controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies. - Page 52 Please stop an operation, if any of above symptoms are observed, because there is a possibility that either the refrigerant evaporating temperature control system is faulty, the cooling pipe is clogged, or refrigerant gas is leaking. 6) Press the > key to continuously display the discharge temperature on the local controller. (For more details about display, please refer to “P34 Displaying the status of...

-

Page 53: When Er27 Is Displayed

● When Er27 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Local Functions to be controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies. -

Page 54: When Er31 Is Displayed

- Caution - Please note that if humidification water is directly supplied by the direct water supply line, overflow will not stop until its main valve is closed. If the water is fed from the water tank (standard method), overflow will stop once water level inside the tank falls. 3) Open the drain cock which is attached on the right side of the subtank and drain out humidification Er27 water. -

Page 55: When Er32 Is Displayed

● When Er32 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Local Functions to be controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies. -

Page 56: When Er41, 42, Or 43 Is Displayed

● When Er41, 42, or 43 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Local Functions to be controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies. -

Page 57: When Er45 Is Displayed

● When Er45 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Local Functions to be controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies. -

Page 58: When Er47 Is Displayed

● When Er47 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Local Functions to be controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies. - Page 59 ● When Er48 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Local Functions to be controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies.

-

Page 60: When Er49 Is Displayed

● When Er49 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Local Functions to be controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies. - Page 61 => If inside the chamber does not reach 50℃ even 30 minutes later or if the temperature hardly goes up, please stop the operation because there is a possibility either the thermal heater circuit is disconnected, SSR (solid state relay) is open-circuited preventing the thermal heater from turning on, or the power source for SSR is defective.

- Page 62 ● When Er50 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Functions to be Local controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies.

-

Page 63: When Er51 Is Displayed

● When Er51 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Local Functions to be controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies. -

Page 64: When Er56 Is Displayed

● When Er56 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Local Functions to be controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies. -

Page 65: When Er57 Is Displayed

● When Er57 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the remote Local Functions to be controller, clicking the number will indicate the causes and Messages appear in the activated controller remedies. -

Page 66: When Er61 Is Displayed

● When Er61 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the Functions to be Local remote controller, clicking the number will indicate the Messages appear in the activated controller causes and remedies. remote controller's browser LED display SYSTEM MONIT SENSOR (T THERMO... -

Page 67: When Al26 Is Displayed

● When AL26 is displayed Messages to be displayed when alarm is generated Possible causes and diagnosis * In the case of the Local Functions to be remote controller, clicking the number will indicate the activated controller Messages appear in the remote causes and remedies. -

Page 68: When Al45 Is Displayed

● When AL45 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the Local Functions to be remote controller, clicking the number will indicate the Messages appear in the remote activated controller causes and remedies. -

Page 69: When Al47 Is Displayed

● When AL47 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the Functions to be Local remote controller, clicking the number will indicate the Messages appear in the remote activated controller causes and remedies. -

Page 70: When Al48 Is Displayed

● When AL48 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the Local Functions to be remote controller, clicking the number will indicate the Messages appear in the remote activated controller causes and remedies. -

Page 71: When Al49 Is Displayed

● When AL49 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the Functions to be Local controller remote controller, clicking the number will indicate the Messages appear in the remote activated causes and remedies. - Page 72 5) Once the temperature reaches 50℃, the refrigerator will activate. Press the > key in the local controller to continuously display the refrigerator's operating frequency. (For more details about display, please refer to “P34 Displaying the status of equipment/instrument”. => Once the set value is reached, the operating frequency is maintained at 70 to 90HZ for a few minutes and it AL49 If frequency is maintained at 70 to 90HZ for more than 30 minutes or if the will decrease gradually.

-

Page 73: When Al50 Is Displayed

● When AL50 is displayed Error / alarm No., and messages Possible causes and diagnosis * In the case of the Functions to be remote controller, clicking the number will indicate the Local controller Messages appear in the remote activated causes and remedies. -

Page 74: When Al52 Is Displayed

● When AL52 is displayed Messages to be displayed when alarm is generated Possible causes and diagnosis * In the case of the Functions to be remote controller, clicking the number will indicate the Local activated Messages appear in the remote causes and remedies. -

Page 75: When Al72 Is Displayed

● When AL72 is displayed Messages to be displayed when alarm is Possible causes and diagnosis * In the case of the remote generated Functions to be controller, clicking the number will indicate the causes and activated Local controller Messages appear in the remote remedies. -

Page 76: When Al73 Is Displayed

● When AL73 is displayed Messages to be displayed when alarm is generated Possible causes and diagnosis * In the case of the Functions to be remote controller, clicking the number will indicate the Local activated Messages appear in the remote causes and remedies. - Page 77 Turn on the earth leakage breaker as well as the main power, and reset the error. ③ Use the local controller to set at 20℃, 00%, start a temperature operation, and drain out humidification water After humidification is completely drained out, set and start a inside the humidification pan.

-

Page 78: When Al75 Is Displayed

● When AL75 is displayed Messages to be displayed when an alarm is generated Possible causes and diagnosis * In the case of the Functions to be remote controller, clicking the number will indicate the Local activated Messages appear in the remote causes and remedies. -

Page 79: When Al84 Is Displayed

● When AL84 is displayed Messages to be displayed when alarm is generated Possible causes and diagnosis * In the case of the Local Functions to be remote controller, clicking the number will indicate the activated Messages appear in the remote causes and remedies. -

Page 80: Troubleshooting Problems Without Error/Alarm Display

● Troubleshooting problems without error/alarm display ◇ Chamber operation does not start by pressing the RUN/STOP button. ⇒ Is the chamber operated by using the remote controller? If the chamber is paused by the remote controller by which settings are performed, the operation cannot be resumed by using the local controller. In order to resume the operation, please use the remote controller. -

Page 81: Use Of The Humidification Water Is Extremely Large

◇ Use of the humidification water is extremely large. ⇒ There are a few possible causes such as water level adjustment is defective, malfunctioning, or cable port is not properly sealed. Please check and adjust water level of the humidification pan and wick pan. For more details, please refer to "■... - Page 82 ■ Restarting Operation after Power Failure Press the When the power is restored after power failure occurred, the chamber will display "AL84" and operation will not resume automatically. start button on the local controller or remote controller in order to resume an operation from the step where the operation is previously stopped.

-

Page 83: Maintenance And Inspection

■ Maintenance and Inspection ○ Check points for 1st month inspection Check Points Description Earth leakage Press the test button in order to check the operation breaker of the earth leakage breaker. (Main power switch) Test button Wet bulb gauze wick Replace with a new gauze wick. -

Page 84: Check Points For 3Rd Month Inspection

Cleaning of Open the front panel, take out the filter and vacuum dust with a vacuum cleaner, wash with refrigerator water, then dry completely before reattaching the filter. condenser filter Velcro straps * Operating without the filter attracts dust into the condenser fins and it may cause deterioration in performance. -

Page 85: Check Points For 6Th Month Inspection

○ Check points for 6th month inspection Check Points Description Performance of Maintain the temperature inside the chamber at +90℃. overheat protector Open the service panel at the back of the chamber. There are dials for the “overheat protector” and Overheat protector These instructions slightly... -

Page 86: Check Points For 1St Year Inspection

○ Check points for 1st year inspection Check Points Description "Temperature/humidity Calibrate indicated temperature and humidity values. calibration” ① Check all protective devices. ② Check operation of each instrument (measure operation current, check for abnormal sound, etc.). ③ Measure insulation resistance. ④... - Page 87 ■ Expendable Parts Name of parts Time for replacement Replacement method Wet bulb gauze ・ Within one month or wick when it is dirty or (FX type) stiffened. ・ After a temperature operation is performed at Gauze wick 100℃ or higher. Wick pan * If a temperature operation is performed at +100℃...

- Page 88 Name of parts Time for replacement Replacement method LED lamp If the LED lamp blows ① Turn off the earth leakage breaker. (To check water ② Open the front service panel at the bottom. level inside the water tank.) ③ Remove the water tank.

-

Page 89: Expected Service Life Of Major Parts

■ Expected service life of major parts Name of items Estimated service life Remark Temperature & About 24,000 hours humidity controller Electrical components About 24,000 hours Refrigeration unit The service life varies greatly depending on the test About 20,000 hours temperature, etc. -

Page 90: Warranty Coverage

Warranty Coverage ■ This product went through stringent internal inspections before shipment. However, should this product break down due to manufacturing defects, please contact us or the shop you purchased it from. We will fix any defects which occurred within the warranty period at no cost. However, please note that in the following cases, the above-mentioned warranty terms are not applicable. -

Page 91: Schematic Diagram Of Entire System

◆ Schematic Diagram of entire system... -

Page 92: Schematic Diagram Of Refrigeration System ( Fx/ Fl410N, 420N )

◆ Schematic Diagram of refrigeration system ( FX/ FL410N, 420N ) DC Inverter Refrigerator Refrigerant : HFC404A 1700g Pressure switch : 2.9Mpa Dryer Solenoid valve Expansion valve Evaporating coil... -

Page 93: Schematic Diagram Of Water Circuit

◆ Schematic Diagram of water circuit... -

Page 94: Operable Range Of For Refrigerator Auto/Manual Operation

◆ Operable range of for refrigerator auto/manual operation Temperature Control ℃ Refrigerator Set mode Model No Temperature/ Humidity Control ℃ Refrigerator Set mode Model No Note) When manually operating temperature/humidity test, make sure to use REF1 regardless of the model. -

Page 95: Specifications For Low Temperature & Humidity Chamber Fx Type (- 40 ℃)

◆ Specifications for low temperature & humidity chamber FX type (- 40 ℃) Descriptions inside 【 】 are for 150 ℃ specification (optional) Model No FX410N FX420N FX430N Temperature range -40℃ to +100℃ 【-40℃ to +150℃】 20 to 98%rh (refer to P103 ◆... - Page 96 RJ45 connector for Ethernet, round cable port (φ 54, two ports on right and left sides), viewing window (type 10 and 20 - usable dimension: W210xH303 mm, type 30 - usable dimension: M a i n b o d y W420xH303 mm), window lamp, water tank LED light, caster/adjuster, refrigerator condenser anti-dust filter, humidification vapor collection system, Standard equipment...

- Page 97 ◆ Specifications for low temperature & humidity chamber FX type ( - 70 ℃) Descriptions inside 【 】 are for 150 ℃ specification (optional) Model No FX710N FX720N FX730N Temperature range: -70℃ to +100℃ 【-70℃ to +150℃】 20 to 98%rh (refer to P103 ◆...

- Page 98 Operation manuals (1 set), silicon plugs for φ54 cable port (2), shelf board (1), shelf brackets (2), Accessories portable tank (type 10 and 20: 10 liter x 1, type 30: 10 liter x 2), wick gauzes (12), test certificate 【Note 1】 Performances are guaranteed when ambient temperature is +23℃, rated voltage is used, and no specimens are placed inside the chamber.

- Page 99 ◆ Specifications for low temperature chamber FL type ( - 40 ℃) Descriptions inside 【 】 are for 150 ℃ specification (optional) Model No FL410N FL420N FL430N Temperature range: -40℃ to +100℃ 【-40℃ to +150℃】 From -40℃ to +100℃ 【from -40℃ to +150℃】 Temperature ramp-up rate: Within 45【60】minutes Within 50【75】minutes...

- Page 100 【Note 1】 Performances are guaranteed when ambient temperature is +23℃, rated voltage is used, and no specimens are placed inside the chamber. Indication method conforms with "JTM K 07: Temperature chamber performance testing method and performance indication system." 【Note 2】 If temperature at the installation site falls below +5℃ or exceed +40℃, an alarm may go off or an operation may be stopped indicating an error in order to prevent humidification water from freezing or to protect device from excessively hot environment.

- Page 101 ◆ Specifications for low temperature chamber FL type ( - 70 ℃) Descriptions inside 【 】 are for 150 ℃ specification (optional) Model No FL710N FL720N FL730N Temperature range: -70℃ to +100℃ 【-70℃ to +150℃】 From -70℃ to +100℃ 【from -70℃ to +150℃】 Temperature ramp-up rate: Within 55【75】minutes Within 70【90】minutes...

- Page 102 【Note 1】 Performances are guaranteed when ambient temperature is +23℃, rated voltage is used, and no specimens are placed inside the chamber. Indication method conforms with "JTM K 07: Temperature chamber performance testing method and performance indication system." 【Note 2】 If temperature at the installation site falls below +5℃ or exceed +40℃, an alarm may go off or an operation may be stopped indicating an error in order to prevent humidification water from freezing or to protect device from excessively hot environment.

-

Page 103: Temperature / Humidity Control Range (Fx Type)

Temperature / humidity control range (FX type) ◆ Dry-Bulb Temperature (℃) ※ 1) Although humidity setting range is 20 to 98%, performance cannot be guaranteed if the setting is outside the above temperature/humidity range. ※ 2) Temperature/humidity test below 35℃ cannot be continued for a long period of time as frosting can occur on the chiller. - Page 104 Reliability Testing & Inspection System Integrator http://www.kusumoto.co.jp/ Headquarters 101-0047 1-11-13, Uchikanda, Chiyoda-ku, Kusumoto No.1 TEL.03 (3295) FAX.03 (3233) Tokyo bldg. 8681 0217 Osaka branch 553-0003 5-16-18, Fukushima, Kusumoto No.8 TEL.06 (6452) FAX.06 (6458) office Fukushima-ku, Osaka-shi bldg. 2388 2600 Nagoya branch 460-0003 1-7-1, Nishiki, Naka-ku, Kusumoto No.9...

- Page 105 Temperature and Humidity Test Chamber Setting and Operating Manual First Edition (Oct.29, 2012) When using our products, please first read this operation manual carefully. Please keep this operation manual at a convenient place so that you may refer to it whenever you need.

-

Page 106: Read Before Use

Read before use Please note that we are not responsible for loss of data caused by natural disasters or unexpected accidents such as a lightning strike, power failure, disconnection from a power plug, etc. This device has a function to copy the chamber data into a USB memory using a communication function via Ethernet or a USB memory. - Page 107 Table of Contents Table of Contents READ BEFORE USE ................2 TABLE OF CONTENTS ................. 3 OVERVIEW OF SETTINGS AND OPERATING PROCEDURES ... 6 Local/remote control operation...................... 6 Operation data automatic saving function ..................6 Overview of remote setting ......................7 Equipment required of remote setting ...................

-

Page 108: Table Of Contents

Table of Contents Delayed humidification (dLAy) ..................... 22 Post-test operation (EndP) ......................22 Delayed start of remote control operation (Stdl) ................23 USB memory ..........................25 Operation record ......................... 25 Logs ............................26 REMOTE SETTING ................27 CAUTION ............................ 27 INITIAL SETTING ........................ - Page 109 Table of Contents Chamber............................50 User management ........................51 Chamber name ..........................51 Activation of upper/lower limits warning function ................52 Alarm sound ..........................52 Room lamp ..........................52 Temperature adjustment ......................53 Water supply method (optional) ....................53 IP address ...........................54 FTP .............................54 Mail..............................55 Time ............................57 Language ............................57 Restart ............................57 Initialize settings ..........................57 Maintenance ..........................58...

-

Page 110: Overview Of Settings And Operating Procedures

Overview of settings and operating procedures Overview of settings and operating procedures L L o o c c a a l l / / r r e e m m o o t t e e c c o o n n t t r r o o l l o o p p e e r r a a t t i i o o n n Local controller Operation panel There are two ways to operate the chamber;... - Page 111 Overview of settings and operating procedures O O v v e e r r v v i i e e w w o o f f r r e e m m o o t t e e s s e e t t t t i i n n g g Our product comes with the Ethernet interface as a standard specification.

- Page 112 Overview of settings and operating procedures LAN connector for the E E q q u u i i p p m m e e n n t t r r e e q q u u i i r r e e d d o o f f r r e e m m o o t t e e s s e e t t t t i i n n g g Hardware LAN cable Browser terminal, such as a PC...

-

Page 113: Local Setting (Control Panel)

Local setting (control panel) Local setting (control panel) N N a a m m e e o o f f P P a a r r t t s s Status display area Temperature/humidity display area Menu display area Operation key : Turns on during operation. -

Page 114: Names Of The Menu Display Area

Local setting (control panel) M M e e n n u u Names of the menu display area Unit for time Unit for time Unit for temperature Menu lamp 4-digit segment 2-digit segment Unit for humidity Normal mode and setting mode In normal mode, the display in the menu lamp will change whenever the menu key is pressed and the corresponding set value will be displayed. -

Page 115: Overview Of Local Control Operation

Local setting (control panel) O O v v e e r r v v i i e e w w o o f f l l o o c c a a l l c c o o n n t t r r o o l l o o p p e e r r a a t t i i o o n n Below is an overview of local control operation. -

Page 116: Setting Temperature/Humidity Of A Local Control Operation

Local setting (control panel) Setting temperature/humidity of a local control operation In this section, we will explain how to make settings for 1000 hours of an 85 , 85% operation as an example. Press the SET key in order to In the setting mode, the first Temperature and humidity are set change from normal mode to... - Page 117 Local setting (control panel) Upper temperature and humidity Now use this menu to set the Press the SET key. limits are set at 10 and 50% lower limits. This will change the setting mode respectively. to normal mode. upper temperature limit at 10 Press the menu key to set the and upper humidity limit at 50%.

-

Page 118: Starting A Local Control Operation

Local setting (control panel) Starting a local control operation Press and hold Press and hold the RUN/STOP An operation will start. key (2 seconds) Change settings of a local control operation In the case of a local control operation, settings can be changed during the operation. Press the SET key in order to Press the SET key in order to change to setting mode. -

Page 119: Operations During A Local Control Operation

Local setting (control panel) O O p p e e r r a a t t i i o o n n s s d d u u r r i i n n g g l l o o c c a a l l c c o o n n t t r r o o l l a a n n d d r r e e m m o o t t e e c c o o n n t t r r o o l l o o p p e e r r a a t t i i o o n n s s Operations during a local control operation During a local control operation, the local controller supersedes over the remote controller. - Page 120 Local setting (control panel) S S t t a a t t u u s s d d i i s s p p l l a a y y a a r r e e a a Local control operation Remote control operation If RUN lamp is blinking, this means that it is within 5 minutes after a delayed operation is started...

- Page 121 Local setting (control panel) C C h h e e c c k k i i n n g g s s e e t t v v a a l l u u e e s s Whenever the MENU key is pressed, display changes. Display temperature and Set temperature and humidity values are humidity.

- Page 122 Local setting (control panel) D D i i s s p p l l a a y y i i n n g g e e a a c c h h v v a a l l u u e e To change display items is displayed according to Page 19 "Display of each value".

-

Page 123: Display Of Each Value

Local setting (control panel) Display of each value Steps Indicates the present step of the program. (St) Example: Step 3 is displayed. Wet bulb temperature Indicates the current temperature of the wet bulb. (Wb) Example: WB temperature is 83.1 . REF 1 EVAPORATING Indicates the current REF1 evaporating temperature. - Page 124 Local setting (control panel) Inverter frequency Indicates the current REF1 inverter frequency. (Fq) Example: Current frequency is 32Hz. Thermal heater output Indicates the current thermal heater output value. (ot) Example: Current output is 48%. Humidification heater Indicates the current humidification heater output output value.

- Page 125 Local setting (control panel) O O t t h h e e r r s s e e t t t t i i n n g g s s This is an overview regarding the temperature/humidity operation when other settings are activated with the local controller. Start Humidity Set temperature is reached...

-

Page 126: Delayed Humidification (Dlay)

Local setting (control panel) Delayed humidification (dLAy) In normal mode, press the Delayed humidification setting Then, the 2-digit segment on the and MENU key at the same time. screen will be displayed. right blinks. The word "dLAy" blinks. Press the key to turn the ON or OFF is indicated in turn. -

Page 127: Delayed Start Of Remote Control Operation (Stdl)

Local setting (control panel) Then, the 2-digit segment on the Select OFF. Press the SET key to go back to right blinks. Post-test operation setting is the normal mode. deactivated. ON or OFF is indicated in turn. Select ON in order to activate delayed humidification function. - Page 128 Local setting (control panel) In normal mode, press the Delayed humidification setting Post-test operation setting screen and MENU key at the same time. screen will be displayed. is displayed. The word "dLAy" blinks. The word "EndP" blinks. Press the MENU key again. Press the MENU key again.

-

Page 129: Operation Record

Local setting (control panel) U U S S B B m m e e m m o o r r y y Creating a folder of a preselected name in the USB memory will allow users to save operation data and log data in the USB memory. Unsaved operation record since the USB memory was previously inserted will be saved in the USB memory. -

Page 130: Logs

Local setting (control panel) Logs A file named "etac_history" is created in the USB memory. Insert the USB memory into the USB connector. Access to the USB memory starts. Wait until it ends. Operation logs as well as error logs are saved. The file name is as follows. -

Page 131: Remote Setting

Remote setting Remote setting CAUTION Kusumoto Chemicals, Inc. owns the copyright of this software. Some or all of this software and the manual cannot be used or reproduced without prior consent. The specification of this software and the content of the manual may be changed without prior notice in the future. This software cannot be used with our 3CS (environmental test chamber central control and monitoring system) software. -

Page 132: Connecting To A Network

Remote setting I I N N I I T T I I A A L L S S E E T T T T I I N N G G Connecting to a network LAN connector Connect the chamber with a browser terminal such as a PC (hereinafter, referred to as a PC) using a LAN cable. -

Page 133: Setting An Ip Address

Remote setting Setting an IP address (Windows 7) Open the control panel. Open the View Network Status and Tasks Open Change Adapter Settings Open Local-area Connection Right-click and open Property. - Page 134 Remote setting (Windows 7) from previous page Select Internet Protocol Version 4 (TCP/IPv4) and open Property. For setting IP address, enter 192.168.0.2. For setting Subnet mask, enter 255.255.255.0. Press OK to complete the setting. * When changing IP address-related settings, administrator rights may be required.

-

Page 135: Checking Ip Address

Remote setting Checking IP address IP address of the chamber is displayed. Press and hold for 3 seconds In normal mode, press and hold While these keys are pressed, Releasing either one of the keys will key and then press and IP address is displayed. - Page 136 V V a a r r i i o o u u s s s s c c r r e e e e n n s s The top screen will be displayed after login. Clicking a button or link (blue underline) will switch the screen *1. Login ETAC Research Settings Saved folder list Program list...

- Page 137 Remote setting Login Enter user name and a password. User name and a password may be saved depending on the browser or setting. In order to activate or deactivate user name When logging in for the first time, log in as an "administrator." or a password saving function, please refer to the help information of the browser that you use.

-

Page 138: Overview Of Program Operation

Remote setting Overview of program operation This section describes an overview of program operation starting from creation of a new program up to starting the operation. Creation of a new program Create a new test program. Register Registration of a program Register the newly created program. -

Page 139: About The Top Screen

Remote setting The confirmed program operation will be Starting an operation started. If you enter a remark, it will be displayed in an operation log or saved folder. Select "YES" to start an operation. An operation will start. Once an operation is started, the program will be automatically controlled. -

Page 140: Pause

Remote setting Even when the remote controller is used, indication of activation or deactivation varies depending on a login user's authority. Pause If this button is activated, operation can be stopped. START If this button is activated, operation can be started. If a remote control operation is stopped with the local controller, this button will not be activated because the remote controller cannot resume the operation. -

Page 141: Skip Function

Remote setting About the top screen from previous page) Skip function If this button is activated, the user can skip the current step to proceed to the next step. HOLD Hold function If this button is activated, the temperature and humidity at the time when the HOLD button is pressed can be maintained. The program will stop while this function is activated and the step elapsed time is also not added. -

Page 142: Various Operations

Remote setting Various operations Settings of test time setting and wait function at the starting step Assuming that the current temperature is 85 , following are four examples (A) to (D) that can be identified. Settings of test time setting and wait function at the starting The chamber is operated at maximum capacity to step decrease the temperature to 20 . - Page 143 Remote setting Settings of test time setting and wait function at the starting step from previous page) Temperature is decreased from 85 to 20 at a fixed gradient for 2 hours. If the temperature reaches 20 in 2 hours: The test continues as programmed. If the temperature does not reach 20 in 2 hours: After the temperature reached 20 , step 1 is carried out...

- Page 144 Remote setting The figures above show how the test time and wait function are correlated using the start step for an example, but the same principle applies to other steps as well. Depending on whether the wait function is set or not, either (E) or (F) pattern will be performed. The chamber is operated at maximum capacity to decrease the temperature to 20 .

-

Page 145: Operations When Upper Or Lower Limit Is Reached

Remote setting Operations when upper or lower limit is reached There are two options as described below. Alarm Stop an operation by error indication For more details, please refer to Page 51 Monitoring method When temperature increases When temperature decreases When humidity increases/decreases While both temperature and humidity are monitored, once temperature exceeds... - Page 146 Remote setting Operations when upper or lower limit is reached from previous page) Upper and lower temperature limits Upper and lower humidity limits Humidity is not monitored while the temperature is increased or decreased at the fixed gradient. When a temperature and humidity test is performed, humidity monitoring will be stopped once the temperature...

-

Page 147: Program List

Remote setting Program list Click [Program] The list of registered programs is displayed. The existing program can be exported or imported. UP to 100 programs can be registered. To create a new test program. For more details, please refer to Page 44 Confirm / edit program EDIT To edit selected program. -

Page 148: Confirm / Edit Program

Remote setting Confirm / edit program Click the Program button on the TOP screen to display Program List. Then, click either Program Name Link or NEW button to display the screen on the right. REGISTER If this button is indicated, a program can be registered. (After registration, the screen returns to program list) Confirm If this button is indicated, a program can be confirmed. - Page 149 Remote setting Confirm / edit program from previous page) Whole program or a part of the step can be repeated. Repeat By pressing the GRAPH button, a graph can be viewed even registration is not completed. Entire repetition is not reflected in a graph. Repeated until it is manually stopped.

- Page 150 Remote setting Confirm / edit program from previous page) Graph Details of a program can be viewed in a graph. Display Details of a program can be viewed even if it is still in the middle of the editing process. If the current program in operation is displayed the current step is highlighted.

-

Page 151: Saved Folders

Remote setting Saved folders Click a [Save folder]. Perform necessary settings in order to save a folder. Clicking a data program name will change the screen to download screen. Up to 30 folders can be registered. Up to the latest 30 data files can be displayed in a saved folder. New folder To create a new folder. -

Page 152: Logs

Remote setting Logs Click [Logs] Operation log Test results are shown in the operation log. Clicking "Program name link" of a test result will display the download screen. The latest 100 test results are shown. If a new program is confirmed, the status of the chamber will change to STOP preparing for the next test. From start (start of a new program) up to end (end of a program, or confirm next program) can be managed.* The program will be controlled until the next program is confirmed. -

Page 153: Error Log

Remote setting Error log Error and alarm logs are displayed. The latest 50 test results are shown. The record will be indicated in red while causes of an error Expanding the folder mark "+" will display detailed data. or alarm are not resolved. Clicking the error/alarm number will display the causes and The record will turn white once the causes are resolved by resetting remedies screen. -

Page 154: Chamber

Remote setting Chamber Click [Chamber] Other chambers which are connected to the same network can be searched. IP addresses of 1 to 254 on the same network can be detected. Example: When the IP address of the chamber is 192.168.0.1, search is conducted from 192.168.0.1 to 192.168.0.254. Search details are saved and therefore, the results can be easily found. -

Page 155: User Management

Chamber name Only an operator and administrator can display this item. Name of the chamber can be set. Enter when necessary. Setting the chamber name will display the chamber name in the login screen, top screen, ETAC search, mail, etc. -

Page 156: Alarm Sound

Remote setting Settings from previous page) Activation of upper/lower limits warning function Only an operator and administrator can display this item. Select the type of warning. If ALARM is selected, the alarm will sound if the temperature/humidity exceeds its upper/lower limit for 1 minute continuously. However, the operation is continued. -

Page 157: Temperature Adjustment

Remote setting Settings from previous page) Temperature adjustment Only an operator and administrator can display this item. Temperature can be adjusted by referring to the measured wet/dry bulb temperature at the control point. Depending on specimens placed inside the chamber, internal load, etc., indicated temperature and specimen temperature may not match. -

Page 158: Ip Address

Remote setting Setting from previous page) IP address Only administrator can display this item. IP address can be set. CAUTION Setting a wrong IP address will deactivate browser functions. When connecting to the network other than the chamber network, be sure to follow the CAUTION network administrator's directions. -

Page 159: Mail

Only administrator can display this item. Perform mail transmission settings. E-mail Select this. This is an example of setting mail functions from a notification Google's Gmail account named "etac.chamber". function SMTP Required Set SMTP server's domain name or IP Set "smtp.gmail.com". - Page 160 Remote setting This is an example of received message. In addition to regular reporting, if an error occurs or alarm goes off, conditions at that time and error/alarm message will be sent.

-

Page 161: Time

Remote setting Settings from previous page) Time Only administrator can display this item. Time can be set. If wrong time is set, login may be unsuccessful. If wrong CAUTION time is set, please refer to Page 59. Be sure to stop the chamber first before setting time. CAUTION Language Only administrator can display this item. -

Page 162: Maintenance

Remote setting Maintenance Only administrator can display this item. This is to perform maintenance work for the WEB system. Select data and save. After saving to other computers, press "optimization" and delete operation record, operation log, and error log. Only operation record, operation log, and error log are deleted. Other set values, etc. are not deleted. If you wish to delete all data, refer to Page 56 "Initialize setting". -

Page 163: Troubleshooting Tips

Troubleshooting tips Although data such as operation record or set values, etc., are saved, make sure to take a backup just in case. Troubleshooting tips T T h h e e l l o o g g i i n n s s c c r r e e e e n n i i s s n n o o t t d d i i s s p p l l a a y y e e d d C C h h e e c c k k t t h h e e c c o o n n n n e e c c t t i i o o n n . -

Page 164: The Top Screen Is Not Displayed

Troubleshooting tips The top screen is not displayed Check user name and a password. User name and password of the administrator at the time of shipment are [admin] and [admin] respectively. It is not possible to login simultaneously using the same user name from multiple PCs or browsers. - Page 165 Troubleshooting tips (30 minutes). Adjust the time of a PC to match with the chamber, and log in. Adjust both time of the chamber and a PC to correct time. F F i i r r m m w w a a r r e e c c a a n n n n o o t t b b e e u u p p d d a a t t e e d d C C h h e e c c k k b b r r o o w w s s e e r r Compatible browsers are Internet Explorer 8 or higher.

-

Page 166: Glossary

Glossary Glossary TCP/IP (Transmission Control Protocol / Internet Protocol) This is one of the protocols which is used when building a network. It is a combination of TCP protocol and IP protocol. IP address This is an identification number which is used in the network which was built with TCP/IP protocol. If the same IP address is used for multiple network devices, the network does not function normally. - Page 167 Reliability Testing & Inspection System Integrator K K u u s s u u m m o o t t o o C C h h e e m m i i c c a a l l s s L L t t d d . . E E T T A A C C D D i i v v i i s s i i o o n n...

Need help?

Do you have a question about the HIFLEX NEO and is the answer not in the manual?

Questions and answers