Summary of Contents for Endress+Hauser ISEmax compressed air cleaning unit

- Page 1 Products Solutions Services BA00438C/07/EN/17.17 71396473 Operating Instructions ISEmax compressed air cleaning unit (230 V AC) Order no.: 71072583...

-

Page 3: Table Of Contents

Technical data ....18 10.1 Electrical connection ....18 Endress+Hauser... -

Page 4: Document Information

If necessary, Consequences of non- compliance (if applicable) ‣ Action/note Symbols used Symbol Meaning Additional information, tips Permitted or recommended Not permitted or not recommended Reference to device documentation Reference to page Reference to graphic Result of a step Endress+Hauser... -

Page 5: Basic Safety Instructions

Ensure that electrical cables and hose connections are undamaged. Do not operate damaged products, and protect them against unintentional operation. Label damaged products as defective. During operation: ‣ If faults cannot be rectified: products must be taken out of service and protected against unintentional operation. Endress+Hauser... -

Page 6: Product Safety

Instructions. The device is equipped with security mechanisms to protect it against any inadvertent changes to the device settings. IT security measures in line with operators' security standards and designed to provide additional protection for the device and device data transfer must be implemented by the operators themselves. Endress+Hauser... -

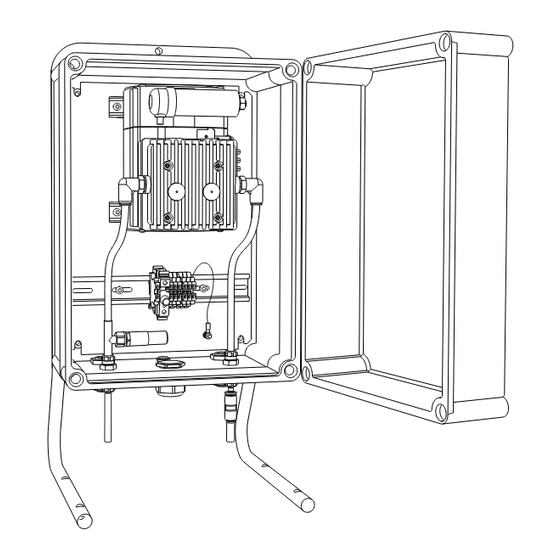

Page 7: Product Description

ISEmax compressed air cleaning unit (230 V AC) Product description Product description Product design A0016120 1 Cleaning unit Pump Housing Suction side with air filter Tube frame (in scope of delivery) Terminal strip with fuse Compressed air supply (to sensor) Safety valve to limit pressure Endress+Hauser... -

Page 8: Incoming Acceptance And Product Identification

• Input and output values • Safety information and warnings ‣ Compare the information on the nameplate with the order. 4.2.2 Product identification Cleaning unit in the housing Order no.: 71072583 Manufacturer's address Endress+Hauser Conducta GmbH+Co. KG Dieselstraße 24 D-70839 Gerlingen Endress+Hauser... -

Page 9: Scope Of Delivery

mark The product meets the requirements of the harmonized European standards. As such, it complies with the legal specifications of the EU directives. The manufacturer confirms successful testing of the product by affixing to it the mark. Endress+Hauser... -

Page 10: Installation

Installation ISEmax compressed air cleaning unit (230 V AC) Installation Installation conditions 278 (10.9) 230 (9.06) Pg21 Pg13.5 A0011377 2 Dimensions in mm (inch) Endress+Hauser... -

Page 11: Mounting The Cleaning Unit

Position the unit mounted on the tubular frame on the railing or an upright post. Secure the tubular frame to the railing or post using a hose clip (provided by customer). Preferably mount the cleaning unit close to the measuring point. Endress+Hauser... -

Page 12: Post-Installation Check

Power consumption too high for the Liquiline alarm relay! Can cause irreparable damage to the base module ‣ Connect the cleaning unit only to terminals of an additional module (AOR, 2R or 4R), not to the alarm relay of the base module. Endress+Hauser... -

Page 13: Post-Connection Check

‣ Check that all connections have been established correctly. ‣ In particular, check all hose connections to ensure they are secure and liquid cannot escape. ‣ Ensure that the supply voltage matches the voltage indicated on the nameplate. Endress+Hauser... -

Page 14: Switching On The Cleaning Unit

Check the compressed air supply to the sensor at regular intervals. As the only wear part, the seal lip of the ribbed cover must be replaced after a long time in service. You know that the seal lip needs to be replaced if the conveying capacity drops noticeably. Endress+Hauser... -

Page 15: Maintenance Tasks

If not, and if air is instead escaping only via the safety valve on the cleaning unit: Check the complete supply line to the cleaning nozzle and check the nozzle itself for contamination and blockage. Remove the contamination. If this is not possible: Replace blocked hoses, connectors or nozzles. Endress+Hauser... - Page 16 Unscrew the fillister-head screw (item 10) using a flat-head screwdriver. Remove thrust washer (item 5). Replace the seal lip (item 12) with the new one in the spare parts kit. Make sure the seal lip is positioned correctly. Endress+Hauser...

-

Page 17: Repairs

The product must be returned if repairs or a factory calibration are required, or if the wrong product was ordered or delivered. As an ISO-certified company and also due to legal regulations, Endress+Hauser is obliged to follow certain procedures when handling any returned products that have been in contact with medium. -

Page 18: Disposal

10.2.1 Conveying capacity 50 l/min (13.2 gal/min), at atmospheric pressure 10.2.2 Operating interval Max. 3 minutes cleaning, break for at least six times the cleaning time 10.3 Environment 10.3.1 Ambient temperature -10 to +55 °C (+10 to +130 °F) Endress+Hauser... - Page 19 ISEmax compressed air cleaning unit (230 V AC) Technical data 10.3.2 Degree of protection IP65 10.3.3 Overheating protection Automatic switch off at T > 130 °C (266 °F) in the motor (winding sensor) Endress+Hauser...

- Page 20 Nameplate ..... . 8 Occupational safety ....5 Endress+Hauser...

- Page 24 www.addresses.endress.com...

Need help?

Do you have a question about the ISEmax compressed air cleaning unit and is the answer not in the manual?

Questions and answers