Table of Contents

Advertisement

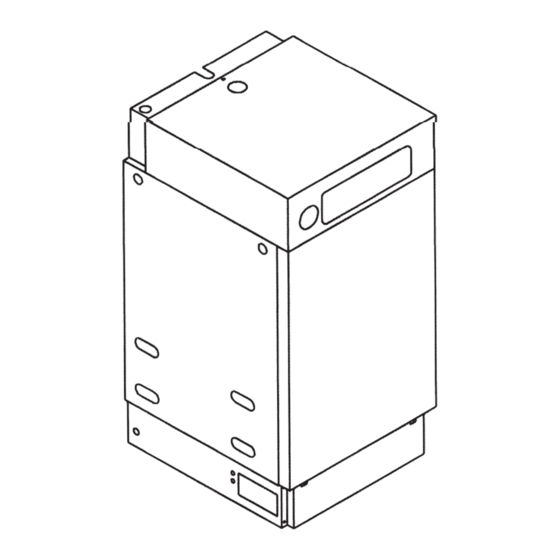

TRANSIT SCREW

MAIN POWER SUPPLY

CABLE ENTRY

LIFTING AND PLUMBING

ACCESS EACH SIDE

EXTERNAL CONTROLS

(AND IMMERSION

HEATER CABLE ENTRY)

PLUMBING ACCESS

EACH SIDE

140

The code of practice for the installation, commissioning

& servicing of central heating systems

BAXI POTTERTON

BROWNEDGE ROAD

BAMBER BRIDGE

PRESTON PR5 6SN

(Technical Helpline) TEL 0870 606 0955

(Service) TEL 0870 606 0933 FAX 0870 606 0966

(Spares) TEL 0870 6060454

"Powermax" is a trademark of Baxi Group Ltd

Publication No. P443 - 12/05

AUTO VENT ACCESS

TOP PANEL

FRONT PANEL

(2 SCREWS)

PLINTH

(4 SCREWS)

(2 SCREWS)

Guide to Panel Removal

Guide to panel removal

Auto vent access

Top panel

Main power supply

cable entry

External controls

cable entry

Lifting and plumbing

access each side

155x x

Upper front panel and

retaining screw

Lower front panel

(2 screws)

Plinth (4 screws)

Advertisement

Table of Contents

Need help?

Do you have a question about the OV 140 P Series and is the answer not in the manual?

Questions and answers

What should the pressure show on the boiler pressure guage

The recommended pressure reading on the PowerMax OV 140 P Series boiler is approximately 3.8 to 4.4 mbar for the 140 model. For the 155x model, the recommended range is 4.8 to 5.5 mbar.

This answer is automatically generated