Table of Contents

Advertisement

INSTALLATION & OPERATION MANUAL

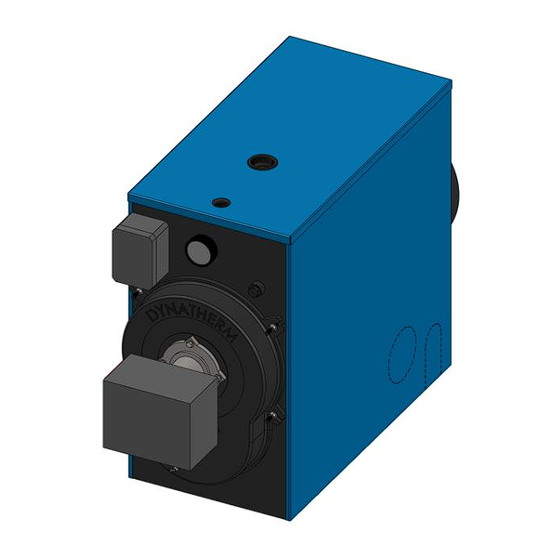

Dynatherm™

OIL-FIRED

•

• PROPANE-FIRED

• NATURAL GAS-FIRED

This boiler has a limited lifetime warranty. A warranty card is included with your new boiler packet. Please note

your serial number, date of installation and contractor's information below.

SERIAL NUMBER:

CONTRACTOR:

43 E. Cherry Rd. | Quakertown, PA 18951 | Ph: 215-536-4078 | Fx: 215-536-8960 | Email: info@dynathermboiler.com

Residential Boilers, Heating & Domestic Hot Water Systems

WARRANTY

Dynatherm™

FP Series Boiler

Models: FP18, FP24, FP36 & FP48

(Optional)

DATE:

PHONE:

Since 1937

Advertisement

Table of Contents

Summary of Contents for dynatherm FP Series

- Page 1 OIL-FIRED • • PROPANE-FIRED • NATURAL GAS-FIRED Dynatherm™ FP Series Boiler Models: FP18, FP24, FP36 & FP48 (Optional) WARRANTY This boiler has a limited lifetime warranty. A warranty card is included with your new boiler packet. Please note your serial number, date of installation and contractor’s information below.

-

Page 3: Table Of Contents

BOILER DESCRIPTION & OPERATION ........................7 BURNER DESCRIPTION ............................8 CONTROLS DESCRIPTION .............................8 FP SERIES BOILER SPECIFICATIONS ........................9 BILL OF MATERIALS ............................10 FP SERIES BOILER LAYOUT ..........................11 BOILER INSTALLATION ............................12 LOCATION..............................13 LEVELING ............................... 14 JACKETING ..............................14 PIPING ................................14 DOMESTIC HOT WATER COIL ........................ -

Page 5: Before Getting Started

Homeowners should never attempt to install, service, repair, upgrade or modify the Dynatherm™ boiler. Dynatherm™ boilers must be installed by a qualified installer/technician in order to validate the warranty. Verify you have the correct size boiler for your home and/or application. Refer to the DOE & IBR ratings chart found in the FP Series Boiler Specification section of this this manual. - Page 6 Page | 6...

-

Page 7: General Description

The Dynatherm™ FP Series Boiler is a high quality head, which houses our exclusive scroll. As the fabricated steel & cast iron boiler of the Scotch gases enter the end head, they’re separated into... -

Page 8: Burner Description

Refer to the manufacturer’s Installation Manual unit. for proper installation and settings. Refer to the manufacturer’s Installation Manual for proper installation and settings. NOTICE Only a qualified Dynatherm™ installer/technician should install, service, set or adjust these units. Page | 8... -

Page 9: Fp Series Boiler Specifications

FP SERIES BOILER SPECIFICATIONS NET IBR HEAT DOMESTIC FIRING HEATING RATING EFFICIENCY TRANSFER WATER HOT WATER STACK MODEL RATE CAPACITY WATER STEADY STATE SURFACE CONTENT COIL GPM TEMP SQ FT COMB AFUE SQ FT 0.65 81.7 89.1 87.3 19.0 0.85 105.4... -

Page 10: Bill Of Materials

BILL OF MATERIALS ITEM DESCRIPTION PART NO. Boiler Shell Front Tube Sheet Rear Tube Sheet Fire Tubes - FP18 306.000 FP24 306.010 FP36 306.020 FP48 306.040 Combustion Tube Liner, Combustion Tube 503.012 Tankless Coil - FP18 500.000 FP24 500.010 FP36 500.020 FP48 500.040... -

Page 11: Fp Series Boiler Layout

FP SERIES BOILER LAYOUT Page | 11... -

Page 12: Boiler Installation

Check with the local authority having jurisdiction for regulations. Mixing valves are not included with your boiler package nor are these valves supplied or sold by Dynatherm™. The tankless domestic hot water coil is positioned in the hottest boiler water inside the boiler shell, just above the fire tubes. -

Page 13: Location

The above chart shows the absolute minimum clearance needed. As an additional safety measure, Dynatherm™ recommends a minimum of 24” at the front end (burner end), 48” at the rear end (coil end), and 12” from the top and sides of the boiler for ideal working access. -

Page 14: Leveling

b. The return must run horizontally and be LEVELING at least 14” from the center of the boiler 1. The boiler should be shimmed level. to clear the side jacket panels. A 2” NPT X 2. If the floor is damp, it’s recommended that the 12”... -

Page 15: Domestic Hot Water Coil

DOMESTIC HOT WATER COIL company. 1. If a tankless domestic hot water coil is c. Dynatherm™ recommends the water to installed on the boiler, be maintained at 85 pH. make connections to the hot water coil and ⚠... - Page 16 Figure 4 – Hot Water Piping with Domestic Hot Water Figure 5 – Hot Water Piping, Multiple Zones Page | 16...

-

Page 17: Ventilation & Chimney Connections

90° elbows in the the boiler. chimney or wall breaching. 5. The Dynatherm™ boiler is a positive pressure 10. The flue side not being used should be boiler in which the flue gases are being forced capped off with a stainless steel flue cap. -

Page 18: Fuel Supply

31/NFPA 54 latest revision and applicable combustible gas detector, soap and water, or provisions of local building codes. similar nonflammable solution. 2. The Dynatherm™ boiler is listed by the Underwriters Laboratories to burn the ⚠ DANGER following gases: ... -

Page 19: Boiler Maintenance

6) Mount the scroll on the fire tubes. Make sure of a leak. the black mark you made with the marker is a. If a leak is found, contact Dynatherm™ for on the top and the scroll is facing the correct the proper procedure to repair or replace way against the tube sheet. -

Page 20: Cleaning Procedure

10) If using No. 2 fuel oil, replace the oil filter CLEANING PROCEDURE element. 1) Remove the four (4) brass nuts at the end 11) If there is any indication that any other head and hinge the head down to expose the gaskets are leaking, replace those gaskets tubes and scroll. -

Page 21: Troubleshooting

Leave the building immediately and call your gas supplier and the fire department. Dynatherm™ requires a qualified installer/technician to service the boiler and we prohibit the homeowner from attempting any repairs, upgrades and/or modifications to the boiler. However, before placing a service call, refer to the below chart for basic troubleshooting problems. -

Page 22: Burner Configurations

BURNER CONFIGURATIONS APPLIANCE TURBULATOR PUMP OR FLANGE VENTING BOILER BURNER CONTROL OR HEAD MANIFOLD INSERTION ARRANGEMENT MODEL MODEL PRE/POST PURGE NOZZLE SIZE SETTING SETTING PRESSURE DEPTH FP18 Oil EZ-1 PRO 0.55x45°B 0.60 0.50 Chimney Vented FP18 Oil EZ-1 PRO 6020002 10/10 0.65x45°B 0.65 0.60/0.65... - Page 23 APPLIANCE NATURAL NATURAL VENTING BOILER BURNER CONTROL GAS AIR PROPANE PROPANE ARRANGEMENT MODEL MODEL PRE/POST PURGE FIRING RATE ORIFICE SETTING ORIFICE AIR SETTING FP18 Gas EZ-GAS 91 MBH 13/64” 9/64” 6020002FR Chimney Vented FP18 Gas EZ-GAS 105 MBH .213” (#3) 9/64”...

- Page 24 APPLIANCE FIRING RATE TURBULATOR PUMP OR FLANGE VENTING BOILER BURNER INPUT VALUE US NOZZLE OR HEAD MANIFOLD INSERTION ARRANGEMENT MODEL MODEL GPH OR BTU/HR SIZE SETTING SETTING PRESSURE DEPTH 40 F5 FP24 Oil 0.85 GPH 0.75x80°B w/SBT 40 F5 Chimney Vented FP24 Oil 1.00 GPH 0.85x80°B...

-

Page 25: Ratings And Approvals

RATINGS AND APPROVALS All Dynatherm™ boilers are rated in accordance with I-B-R recommendations. The Dynatherm™ ASME boilers have the “H” constructed stamp as well as a National Board registration number. All burners and electrical components provided by the manufacturer with a Dynatherm™ boiler are UL approved. - Page 26 Page | 26...

-

Page 27: Notes

NOTES Page | 27...

Need help?

Do you have a question about the FP Series and is the answer not in the manual?

Questions and answers