Table of Contents

Advertisement

Quick Links

Section title

1. Safety Instructions

2. Specifications

3. Installation

4. Operation

5. Maintenance

6. Chemical Feed Pump Size Guide

7. Troubleshooting

8. Parts List

9. Warranty and Service

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

ROLA-CHEM

®

Pro Series Pump

INLET

PN 522105

07/10/2019

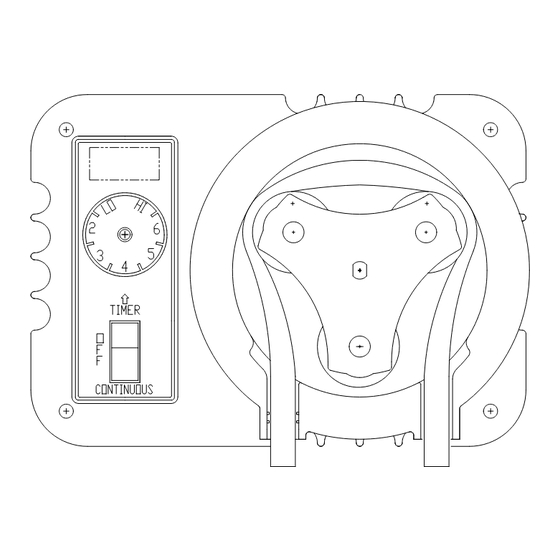

PRO SERIES PUMP

Installation & Parts Manual

OUTLET

Page

2

3

4

5

5

8

9

10

12

Page: 1 of 12

Advertisement

Table of Contents

Summary of Contents for ROLA-CHEM Pro Series

- Page 1 PRO SERIES PUMP Installation & Parts Manual INLET OUTLET Section title Page 1. Safety Instructions 2. Specifications 3. Installation 4. Operation 5. Maintenance 6. Chemical Feed Pump Size Guide 7. Troubleshooting 8. Parts List 9. Warranty and Service IMPORTANT SAFETY INSTRUCTIONS...

- Page 2 1.10 WARNING! Risk of Chemical Overdose/Exposure. Minimize amount of chemical on site that is available to dispense. Size the feeder and container to pool/spa capacity. Dilute chemical for small bodies of water. Page: 2 of 12 ROLA-CHEM ® Pro Series Pump PN 522105 07/10/2019...

-

Page 3: Specifications

1.5 MIN 0.78 11.0 33.4 9 MIN 4 SEC 0.90 12.0 Capacity in this table is intended as a guide. Actual output may vary based on actual environment. Page: 3 of 12 ROLA-CHEM ® Pro Series Pump PN 522105 07/10/2019... -

Page 4: Installation

Tools required – Phillips screwdriver & adjustable wrench, 23/32” drill & ½” pipe tap (NPT) or 7/16” drill & ¼ “ pipe tap (NPT) ® 3.1 Install the ROLA-CHEM pump in an area protected from natural elements (sun, rain, freezing, etc.). -

Page 5: Operation

CAUTION! Pump must be turned off when backwashing filters. 4. Operation 4.1 Before placing the ROLA-CHEM ® pump in operation, lubricate the Pinch Tube with silicone lubricant (supplied in the literature kit) and install per Pinch Tube Assembly replacement instruction section 5.2. - Page 6 5) Lubricate Pinch Tube Assembly as noted in OPERATION section 4.1. Lay inlet end (without clamp) in inlet port on left with about ¾” of Pinch Tube protruding from housing. See Figure 2. Figure 3 Figure 4 Page: 6 of 12 ROLA-CHEM ® Pro Series Pump PN 522105 07/10/2019...

- Page 7 A Pinch Tube Assembly under light duty may last more than one season, but replacing the Pinch Tube Assembly may prevent damaging the pump or an unscheduled maintenance call. 5.4 Crystal buildup is seldom a problem with ROLA-CHEM ® pumps. However, it may be necessary to flush the pump tubing.

- Page 8 Pump size must be in compliance with local health codes. When in doubt about pump size ® or if different brand feed pumps are used, consult your supplier or ROLA-CHEM NOTE: ORP/pH controllers will not function properly with an over or undersized feeder.

- Page 9 Motor bearings Replace motor. Pump motor starts and High temperatures Check fan and replace if damaged. stops with switch in Improve ventilation to pump. CONTINUOUS position. Switch Replace switch. Page: 9 of 12 ROLA-CHEM ® Pro Series Pump PN 522105 07/10/2019...

-

Page 10: Parts List

ITEM 18 INCLUDES: PINCH TUBE ASSEMBLY (ITEM 19) AND ITEMS 23 THRU 27 NOTE B: PINCH TUBE ASSEMBLY ITEM 19 INCLUDES: TYGON (OR NORPRENE) PINCH TUBE, CLAMP (ITEM 21) AND FITTING (ITEM 22) Page: 10 of 12 ROLA-CHEM ® Pro Series Pump PN 522105 07/10/2019... - Page 11 MODELS 8.75 7.75 ITEMS 9 - 12 FOR RC252 6.25 37 38 GROUND SCREW & LOCK WASHER (NOT SHOWN) ARE FOR FASTENING GROUND WIRE TO BACK OF MOTOR Page: 11 of 12 ROLA-CHEM ® Pro Series Pump PN 522105 07/10/2019...

-

Page 12: Warranty And Service

(1) year. ® If this unit fails within the one (1) year period, it will be repaired or replaced (ROLA-CHEM ® option) at no charge, when returned to ROLA-CHEM with proof of purchase receipt.

Need help?

Do you have a question about the Pro Series and is the answer not in the manual?

Questions and answers