Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Coldelite EPS 60 XP

- Page 1 INSTRUCTIONS HANDBOOK EPS 60 XP APPLICARE TARGA CARATTERISTICHE...

- Page 2 COLDELITE. The purchaser has the wright to reprint it for his own office use. COLDELITE policy pursues a steady reasearch and development, thus it reserves the right to make changes and revisions whenever deemed necessary and without being bound to previous statements to the purchaser.

-

Page 3: Table Of Contents

EPS XP INDEX SECT. FOREWORD ......................5 INSTRUCTION HANDBOOK ................... 5 PURPOSE ........................5 HANDBOOK STRUCTURE ..................5 ADDITIONAL DOCUMENTATION ................. 5 CONVENTIONAL SYMBOLS ................... 6 SAFETY ........................7 QUALIFICATION OF THE STAFF ................. 7 WARNING ......................... 7 SECT. 1 GENERAL INFORMATION GENERAL INFORMATION .................. - Page 4 EPS XP SEC. 5 CLEAN OUT, DISASSEMBLING AND REASSEMBLING OF PARTS IN CONTACT WITH THE PRODUCT EXTERIOR CLEAN OUT ..................23 PRELIMINARY CLEAN OUT ................23 DISASSEMBLING THE SPIGOT PISTON ............23 DISASSEMBLING THE TANK COVER ............... 24 DISASSEMBLING THE BEATER ................. 24 HYGIENE .........................

-

Page 5: Sect. Foreword

Topics relevant to a correct use of the machine have been analyzed in order to keep unchanged in the long run quality features charachterizing COLDELITE machines all over the world. A significant part of this handbook refers to the conditions necessary to the machine use and to the necessary procedure during cleanout as well as routine and special maintenance. -

Page 6: Conventional Symbols

He/she is qualified for interventions on electrical and refrigeration components. COLDELITE ENGINEER He/she is a skilled engineer the manufacturer assigned to field interventions for complex jobs under particular conditions or in accordance with agreements made with the machine's owner. -

Page 7: Safety

It is forbidden to remove panels in order to reach the machine inside before having disconnected the machine. • COLDELITE is not responsible for any accident that might happen during operation, cleaning and/or servicing of its units, if this warning has not been fully complied with. - 7 -... - Page 8 EPS XP eps xp_EN - 09/10 - ed. 2 - 8 -...

-

Page 9: General Information

EPS XP GENERAL INFORMATION 1.1 GENERAL INFORMATION 1.1.1 Manufacturer's identification data The machine has a data plate carrying manufacturer data, machine type and serial number, assigned when it is manufactured. Copy of machine data plate to be found on first page of this handbook. Legend: A= Serial number B= Machine type... -

Page 10: Technical Features

EPS XP COLDELITE recommends to always use high quality ingredients for the preparation of confectionery products, in order to satisfy your customers, even the most hard-to-please ones. Any saving made to the prejudice of quality will surely turn into a loss much bigger than the saving itself. -

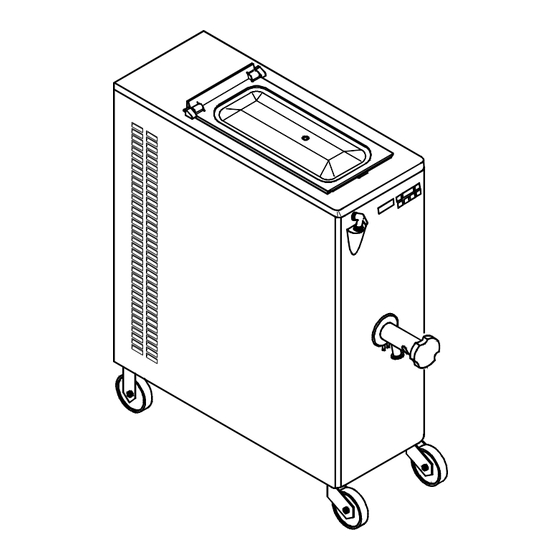

Page 11: Machine Groups Location

EPS XP 1.2.3 Machine groups location Caption 1 Tank with cover 2 Control panel 3 Dispensing spigot 4 Spout 1.3 INTENDED USE EPS XP must only be used conforming with contents of paragraph 1.2.1 "General Information", within the functional limits hereunder reported: Voltage: ±10% Air min. -

Page 12: Weee (Waste Electrical And Electronic Equipment)

EPS XP 1.7 WEEE (Waste Electrical and Electronic Equipment) In accordance with European Directive 2002/96/EC on WEEE (Waste Electrical and Electronic Equipment), the presence of the above symbol on the product or on its packaging indicates that this item must not be disposed of in the normal unsorted municipal waste stream. Instead, it is the user’s responsibility to dispose of this product by returning it to a collection point designated for the recycling of electrical and electronic equipment waste. -

Page 13: Room Necessary To The Machine Use

EPS XP INSTALLATION 2.1 ROOM NECESSARY TO THE MACHINE USE The machine must be installed in such a way that air can freely circulate all around. Rooms for the approach to the machine must be left free in order to enable the operator to act without constraint and also to immediately leave working area, if need be. -

Page 14: Machines With Watercooled Condenser

EPS XP 2.4 MACHINES WITH WATERCOOLED CONDENSER To make the machine run, a watercooled machine must be connected to running water supply, or to a cooling tower. Water must have a pressure of 0.1 MPa and 0.8 MPa (1-8 bar) at least, and a delivery at least equal to the estimated hourly consumption. -

Page 15: Location

Motor installed in the machine is of the type with lubrication for life; no action of checking/ replacing or topping up is necessary. Gas filling necessary to the freezing system is carried out at COLDELITE works during machine postproduction testing. - Page 16 EPS XP eps xp_EN - 09/10 - ed. 2 - 16 -...

-

Page 17: Machine Safety Warnings

EPS XP INSTRUCTIONS FOR USE 3.1 MACHINE SAFETY WARNINGS When using industrial equipment and plants, one must be aware of the fact that drive mechanisms (rotary motion), high voltage components, as well as parts subject to high temperatures may cause serious damages to persons and things. Who is in charge of plant safety must be on the look-out that an uncorrect use or handling is avoided Safety devices are neither removed nor tampered... -

Page 18: Controls

EPS XP 3.3 CONTROLS 3.3.1 Push-button panel The machine is provided with a push-button panel on its front side; each push-button has symbols explaining relevant functions. 3.3.2 Functions Function insert leds When one of the leds on top left side of each push button switches on, it means the the function corresponding with the symbol next to the same led, has been inserted. - Page 19 EPS XP Cooling In cooling mode - Compressor - Solenoid valve (EVF) - Beater (high speed = clowise rotation) will be activated In cooling, too, the beater always runs together with the Compressor. After selecting the Cooling push-butrton, the display will show +04°C +14°C When the set value is reached, Compressor, solenoid valve and Beater will...

-

Page 20: Machine Starting

EPS XP 3.4 MACHINE STARTING After washing, sanitizing and thoroughly rinsing the machine right before its use, as per previous descriptions, pour the mix into the tank according to the quantity desired and respecting the minimum and maximum values shown in the table (Sec. 1.2.2); the tank is provided with an inside graduation for an approximate indication of mix quantity therein contained (see picture below). -

Page 21: Alarms On Display

EPS XP SAFETY DEVICES 4.1 ALARMS ON DISPLAY The machines EPS XP are provided with a series of safety devices to machine and opertors' safeguard. Every time a safety device trips, a signal of alarm is displayed on the second line of the machine display. -

Page 22: Blackout

EPS XP 4.2 BLACKOUT Blackout is under CPU control in any Pasteurization cycle. In particular, if the machine was in: - Stop or Beating, on power return, it will return to Stop position. - Pasteurization Heating (65°C - 85°C - 90°C): on power return, the mahcine will return to Heating and will set the stored set value. -

Page 23: Exterior Clean Out

EPS XP CLEAN OUT, DISASSEMBLING AND REASSEMBLING OF PARTS IN CONTACT WITH PRODUCT IMPORTANT Cleaning and sanitizing must be carried out at the end of every working day with utmost care in order to guarantee quality of production in the respect of all hygienic rules. 5.1 EXTERIOR CLEAN OUT Eliminate dust from your machine and also the protective film which, before delivery, it was covered with. -

Page 24: Disassembling The Tank Cover

EPS XP 5.4 DISASSEMBLING OF TANK COVER Note: The machine is provided with a safety device on its cover; every time you lift the cover while the machine is running, the machine will stop (See ALARM OPEN). The tank cover is completely removable, whereas the hinges are fastened to the machine. Place the cover vertically;... -

Page 25: Hygiene

EPS XP HYGIENE Mix fat contents are ideal fields for proliferation of mildew and bacteria. To eliminate them, parts in contact with mixes and creams must be thoroughly washed and cleaned. Stainless steel materials as well as plastic and rubber ones used for the construction of these parts and their particular design make cleaning easy, but cannot prevent the growth of mildew and bacteria if not properly cleaned. - Page 26 EPS XP eps xp_EN - 09/10 - ed. 2 - 26 -...

-

Page 27: Service Typology

In the event of breaking or wear of one or more parts, request the new ones directly to a Coldelite Engineer, always detailing machine type and serial number printed on data plate you will find on the rear of the machine. -

Page 28: Table Of Equipment

EPS XP 6.5 TABLE OF EQUIPMENT 1225 1251 Description Position Nr OR extractor Blister Swab D 30x640 Food-grade lubrificant tube Brush 1225 1251 eps xp_EN - 09/10 - ed. 2 - 28 -... -

Page 29: Troubleshoot Guide

EPS XP TROUBLESHOOT GUIDE TROUBLE CAUSE CURE Machine does not start The main switch is off Turn it on Machine is unplugged Check and plug in Control unit does not Control unit Replace the control unit accept a control Call after-sale service Product coming out from Gasket is strained, cut, etc., Check and replace through a...

Need help?

Do you have a question about the EPS 60 XP and is the answer not in the manual?

Questions and answers