Summary of Contents for ADT 7900 Uno Dicing Series

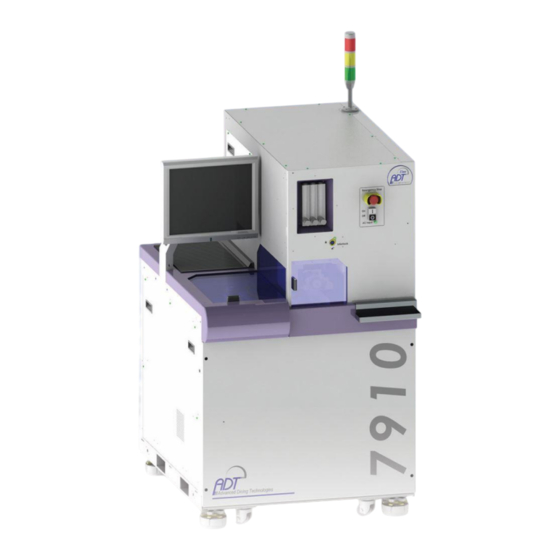

- Page 1 Your Resource for Advanced Dicing Solutions ADT 7900 Uno Dicing Series Site Preparation and Installation Supplement P/N 97910-9000-001-01 April 2014...

- Page 2 5 Hamada St., Hi-Tech Park (South), P.O.Box 87, Yokneam 20692, Israel Tel.: 972-4-8545222, Fax: 972-4-8550007 Confidential This information is the property of Advanced Dicing Technologies Ltd. Any reproduction, publication or distribution to a third party is strictly forbidden, unless written permission is given by an authorized agent of ADT.

- Page 3 ADT Model 7900 Uno Dicing Series Installation Supplement Safety First SAFETY FIRST ADT believes that the safety of personnel working with and around our Systems is the most important consideration. Please read all safety information below and in the Operations and Maintenance Manuals before attempting to operate the System or perform any maintenance function.

- Page 4 Site Preparation and Installation Supplement Safety Features Safety Features Our Systems are equipped with the following safety features. Look at them and get to know them. : Pressing the red E MERGENCY UTTON MERGENCY UTTON stops ALL activities in the System. : Use the C ...

- Page 5 Reference Documents ADT Model 7900 Uno Semi-Automatic Dicing System Operations Manual, 97910-9002-000-XX. ADT Model 7900 Uno Semi-Automatic Dicing System Maintenance Manual, 97910-9005-000-XX. ADT 7900 Uno Dicing Series Schematics and Illustrated Parts Book, 97910-9003-000-XX. P/N 97910-9000-001-01 Ver. 04/2014...

- Page 6 Site Preparation and Installation Supplement Symbols CONVENTIONS This section explains basic symbols and conventions used in this Manual. Symbols The following symbols have been inserted on the left hand side of the text in order to make it easier for the User to perform procedures: Symbol Description Note: Information given in a note describes how the Model...

- Page 7 ADT Model 7900 Uno Dicing Series Installation Supplement Conventions Abbreviations and Acronyms Ampere Broken Blade Detector cf/m Cubic Feet per minute cm/h Cubic Meters per hour Grams of force Graphical User Interface Hertz (frequency) High Torque Spindle Inch in. Hg...

-

Page 8: Table Of Contents

Site Preparation and Installation Supplement Table of Contents TABLE OF CONTENTS Installing the System _________________________ 1 Specifying System Elements __________________ 2 Workpieces _______________________________________________ 2 Blades ____________________________________________________ 2 Broken Blade Detector (Optional) _____________________________ 2 Spindle ___________________________________________________ 3 X-Axis (Feed) ______________________________________________ 3 Y Axis (Indexing) ___________________________________________ 3 Z Axis (Cut Depth) __________________________________________ 4 Theta-Axis (Rotational) ______________________________________ 4... - Page 9 ADT Model 7900 Uno Dicing Series Installation Supplement Table of Contents Parts and Accessories Shipped with the System ________________ 19 Positioning the System on your Production Floor _______________ 21 Securing the System to the Production Floor___________________ 23 Connecting Utilities to the System ___________________________ 23...

- Page 10 Site Preparation and Installation Supplement List of Tables LIST OF TABLES Table 1. Workpiece Maximum Measurements ___________________________________ 2 Table 2. Blade Settings _____________________________________________________ 2 Table 3. Spindle Specifications _______________________________________________ 3 Table 4. X Axis Details _____________________________________________________ 3 Table 5. Y Axis Details _____________________________________________________ 3 Table 6.

- Page 11 ADT Model 7900 Uno Dicing Series Installation Supplement List of Figures LIST OF FIGURES Figure 1. Indicators _______________________________________________________ 11 Figure 2. Crate and Steel Bands _____________________________________________ 13 Figure 3. Right Shipping Bracket ____________________________________________ 14 Figure 4. Left Shipping Bracket ______________________________________________ 14 Figure 5.

-

Page 13: Installing The System

ADT Model 7900 Uno Dicing Series Installation Supplement Installing the System INSTALLING THE SYSTEM Installing the System lists and describes the system specifications and prerequisites, as well as the procedures that you must perform, in order to install the system in your business. -

Page 14: Specifying System Elements

Site Preparation and Installation Supplement Workpieces SPECIFYING SYSTEM ELEMENTS Specifying System Elements describes various elements in the system and includes the accepted specifications of each of the following elements: Workpieces on page 2. Blades on page 2. Broken Blade Detector (Optional) on page 2. ... -

Page 15: Spindle

ADT Model 7900 Uno Dicing Series Installation Supplement Specifying System Elements Spindle The system is equipped with twin facing, air bearing, DC brushless, water cooled, 2" spindles. Table 3. Spindle Specifications Parameter Details Spindle type DC, Brushless Maximum Rotation Speed... -

Page 16: Z Axis (Cut Depth)

Site Preparation and Installation Supplement Z Axis (Cut Depth) Z Axis (Cut Depth) The Z Axis includes ball bearing slides and stepper motor. Table 6. Z Axis Details Parameter Details Stroke 40 mm Minimal Step (resolution) 0.2 µm Accuracy (unidirectional) 2 µm Repeatability 1 µm... -

Page 17: Preparing The Site

"Pneumatics" on page 8. "Site Dimensions" on page 8. Note: If you require fastening the system to the floor, contact ADT for the securing kit. Environmental Requirements To ensure proper system performance, verify that the following room specifications are met. -

Page 18: Water

Site Preparation and Installation Supplement Water 3.2.1.1 External Circuit Breaker Table 10. External Circuit Breaker Element Specifications Circuit Breaker Rate Minimum 25A Circuit Breaker Inrush Current Minimum 100A Maximum 2 meters from the rear of the Location/Distance System. Water Caution: Do not use high acid or alkaline water, or water with impurities such as iron, calcium, copper, chlorine, sodium or magnesium, as these can clog or corrode the piping. -

Page 19: Spindle Cooling Water Supply

ADT Model 7900 Uno Dicing Series Installation Supplement Preparing the Site 3.3.3 Spindle Cooling Water Supply Caution: Do not use DI water for spindle cooling water, as it can aggressively attack the cooling surfaces inside the spindle and erode seal areas. -

Page 20: Mist Exhaust

Site Preparation and Installation Supplement Pneumatics 3.4.2 Mist Exhaust Table 15. Mist Exhaust Element Specifications 100 mm O.D. Mist Extension Hose Outlet Center Height from the Floor 965 mm (37.99”) Minimum Suction 300 cm/h (177 cf/m) Pneumatics Table 16. Pneumatics Element Specifications Pressure... -

Page 21: System Dimensions

System Dimensions System dimensions refer to the physical size of the system. Note: You (the customer) must supply all utility connectors and drain hoses; the main power cable (excluding the connector) is provided by ADT. Table 17. System Dimensions Dimension... -

Page 22: Performing System Installation

Note: The test procedures referred to in the Field Acceptance Test Supplement Should also be performed (document P/N 97910-9007-000-XX). Note: If fastening the system to the floor is required, contact ADT and request the securing kit. Read the instructions carefully before beginning the installation, and allow enough time to complete all of the tests and adjustments after installation. -

Page 23: Receiving The System

Inspect the color of the three indicators. If any have turned from clear to red, do not proceed with the installation. Leave the packing crate and the indicators as they are. Immediately contact the local ADT Customer Support representative. Note: Failure to contact the ADT Customer Support representative immediately, in these cases, may result in cancellation of the equipment warranty. -

Page 24: Unpacking The System

Site Preparation and Installation Supplement Unpacking the System Unpacking the System The packing crate consists of a lower pallet, an attached upper pallet, and plywood panels, secured together with staples and screws. Caution: Follow the unpacking procedure exactly as described below. Failure to do so may result in inadvertent damage to the system and the items shipped within. -

Page 25: Uncrating The System

Caution: Examine all of the Shock and Tilt indicators located on the crate panels. If any one of the indicators indicates that the machine had been tilted or jolted, do not proceed. Immediately contact your ADT representative. See "Initial Inspection" on page 11. -

Page 26: Figure 3. Right Shipping Bracket

Site Preparation and Installation Supplement Unpacking the System Detach the right bracket first from the pallet and then from the machine. Right shipping bracket Figure 3. Right Shipping Bracket Carefully insert the forks of the forklift into the forklift slots on the bottom-right side of the machine. -

Page 27: Releasing All Moveable Parts And Unsealing The System

ADT Model 7900 Uno Dicing Series Installation Supplement Performing System Installation 4.3.2 Releasing All Moveable Parts and Unsealing the System Open the lower-front and lower-rear panel and examine the Tilt indicators adhered to the casting. See "Initial Inspection" on page 11. -

Page 28: Figure 7. Y And Z Jigs

Site Preparation and Installation Supplement Unpacking the System Note: The system is shipped with bright yellow securing jigs that prevent the spindles, and all axes, from moving during shipment. Caution: When removing the X Axis securing jig, you must supply air to the X Axis assembly in order to prevent damage to the air bearings. -

Page 29: Figure 9. X Jig

ADT Model 7900 Uno Dicing Series Installation Supplement Performing System Installation X Securing Jig Figure 9. X Jig Assemble the Light Tower: Unpack the Light Tower. Feed the Light Tower electrical plug through the Light Tower hole on the top of the system and connect to the Light Tower power supply outlet. -

Page 30: Figure 11. Air And Water Ports

Site Preparation and Installation Supplement Unpacking the System Remove masking tape from the following locations: Air gun. Visual system shutter. Power cable. Emergency Stop Key Pouch (in the Front Panel). Folding Computer Keyboard. Clipboard. Workpiece door. -

Page 31: Parts And Accessories Shipped With The System

ADT Model 7900 Uno Dicing Series Installation Supplement Performing System Installation Parts and Accessories Shipped with the System Tables 20 through 22 list and describe the parts and accessories that are shipped with the system. Verify that you have received all of the parts and accessories listed in the tables. -

Page 32: Table 21. 2" System Accessories

Site Preparation and Installation Supplement Parts and Accessories Shipped with the System Table 21. 2" System Accessories Part Number Description and Use Quantity Blade Replacement Tool 007700-0908-002-00 Handle (B) Cooling Nozzle (d=2.0mm) Cooling Nozzle (d=2.5mm) 06980-0705-028 Tray targets - in package (for Illumination calibration) Table 22. -

Page 33: Positioning The System On Your Production Floor

Caution: You must remove all masking tape from the system before operating the system. Failure to do so can result in severe damage to the system. ADT is not responsible for any damage caused by masking tape that has not been removed. -

Page 34: Table 23. Locating Taped System Parts

See "Y and Z Jigs" on page 16 Y Jig See "Y Jig" on page 16 10. Make sure that all utilities are ready and available. 11. Contact your local ADT Customer Support representative to complete the system setup. Advanced Dicing Technologies Ltd. -

Page 35: Securing The System To The Production Floor

ADT Model 7900 Uno Dicing Series Installation Supplement Performing System Installation Securing the System to the Production Floor Upon request, ADT can supply you with a special kit for securing the system to the floor. For more information, contact your ADT Customer Support representative. -

Page 36: Table 25. System Utility Connections

Site Preparation and Installation Supplement Connecting Utilities to the System Table 25. System Utility Connections Utility Diameter Connection Point Drain 38 mm Rear of System Spindle cooling water 8 mm Rear of System supply Air supply 12 mm Rear of System DI water supply 12 mm Rear of System... -

Page 37: Connecting The Main Power Cord To The Power Supply

ADT Model 7900 Uno Dicing Series Installation Supplement Performing System Installation Connecting the Main Power Cord to the Power Supply For CE Marked systems - connect the main power cord to the main circuit breaker on the wall. No plug is used. -

Page 38: Securing The Cutting Chuck To The Theta Table

Site Preparation and Installation Supplement Installing the Chuck Verify that the probe has a valid calibration tag. Before using precision measurement equipment, remove oil and fingerprint residues with isopropyl alcohol. Gently wipe the equipment dry with white clean-room paper. After cleaning, handle the equipment with gloves. -

Page 39: Testing Chuck Flatness

ADT Model 7900 Uno Dicing Series Installation Supplement Performing System Installation 4.10.3 Testing Chuck Flatness After placing the cutting chuck on the theta table, perform the chuck flatness test to verify that the chuck meets the following flatness tolerance specifications: Table 26. - Page 40 Installing the Chuck Verify that the measured deviation is within the corresponding specifications. Note: If the deviation is greater than the specification, contact the local ADT representative. Use the X/Y Axis controls to move the measuring probe to the center of the cutting chuck and rotate the theta table to the Angle 90 position.

-

Page 41: Installing The Blades

ADT Model 7900 Uno Dicing Series Installation Supplement Performing System Installation 4.11 Installing the Blades After performing the Chuck Flatness test, the blades should be mounted onto the spindles, as described in the following procedure. To install blades: In the application, from the Main Menu, press Dice; the Dice window appears. -

Page 42: Figure 16. Cooling Block With Bbd

Site Preparation and Installation Supplement Installing the Blades Place the blade holder (if supplied) over the end of the spindle. Pull back the release ring. Repeat the both steps for the second blade. Replace the holding nut and tighten using the torque wrench (until you hear a click). -

Page 43: Performing Chuck To Non-Chuck Delta Measurement

ADT Model 7900 Uno Dicing Series Installation Supplement Performing System Installation Note: If the system is configured with a Button Height Device, during blade installation, the system performs Contact Height on the chuck, followed by a Button height. This process updates the value of Chuck to NCH/Button Delta. - Page 44 Site Preparation and Installation Supplement Installing the Blades INDEX Y2 and Z, 16 Anchoring the Machine, 23 Leveling Mounts, 21 BBD, 2 Blade Main Power Change, 29 Cord, 10, 25 Installing, 29 Specification, 2 Parts and Accessories Shipped with the System, 19 Pneumaics, 8 Center of Gravity, 9 Chuck...

- Page 45 ADT Model 7900 Uno Dicing Series Installation Supplement Index Cutting supply, 6 Drain, 7 Y-axis, 3 General, 6 Spindle cooling supply, 7 Z-axis, 4 X-axis, 3 P/N 97910-9000-001-01 Ver. 04/2014...

Need help?

Do you have a question about the 7900 Uno Dicing Series and is the answer not in the manual?

Questions and answers