Advertisement

Advertisement

Table of Contents

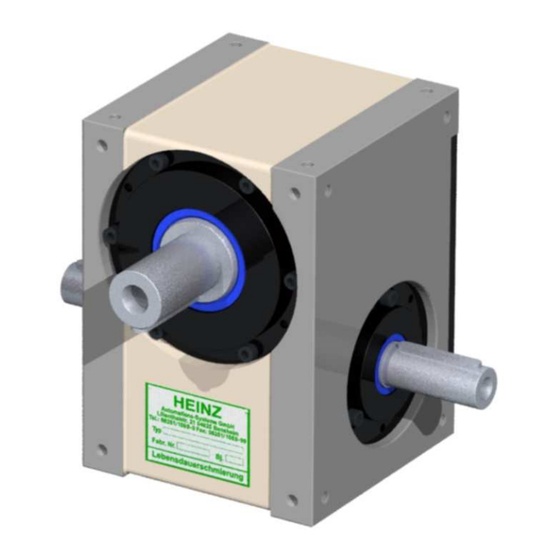

Summary of Contents for Heinz Basic Series

- Page 1 Operating Instructions Parallel shaft cam gear Type Serial No. :...

-

Page 2: Inspection Instructions

C O N T E N T S General Validity Safety instructions Shipment Transport Regulations Weights of gear types Instructions for application of the gears Installation position Mounting of the gear Gear operation Start up Gear function Oil level Interruption operation Important instructions Maintenance Instructions General remark... -

Page 3: Safety Instructions

General Validity These operating instructions are valid for parallel shaft cam gears. They are to be read and applied by all persons in the user’s premises who are made responsible for the installation, operation, maintenance or repair of these gears. For the sake of simplicity, the parallel shaft cam gears will be referred to as “the gears”... - Page 4 Weight of the gears Basic series Weight without motor Gear type Housing [kg] HSP 40 HSP 50 HSP 63 12,5 HSP 80 25,0 HSP 100 43,0 HSP 125 77,0 HSP 160 HSP 200 HSP 250 HSP 315 Modified series Weight without...

- Page 5 Instructions for application of the gears Installation position Due to its universal construction, the gear can be integrated into a machine or a plant in nearly every position required. When placing the order, the customer can preset the installation position, the mounting position and possibly the oil holes.

-

Page 6: Gear Function

3. Start up 3.1 Gear function HEINZ gears form a compact, robust unit which, through the use of accurately calculated disk cams, enable the transformation of a constant input speed into an optimum, precise and impact-free (intermittent) output movement. The cam rollers fitted in the turret are guided precisely in the curve by the hardened and ground cam path. -

Page 7: Important Instructions

Interruption Operation If the dwell angle area of the disk cam is insufficient for the interval of interruption required for production, the interval can be prolonged by using a brake motor. The procedure is initiated by an end position switch which is operated by one of the cams connected to the input shaft. During the start up as well as during operation it has to be observed that after the braking has occurred, the shaft key groove of the input shaft has to be positioned parallel to face 3 of the housing and that it points towards the output shaft ( in case of double shift also a torsion of... -

Page 8: Maintenance Instructions

Maintenance Instructions 4.1. General Remark In case of queries i.e. spare part orders, please state the type and serial number of the gear in question. Drive The maintenance instructions for the gear brake motor or other drive units should be taken from the instructions supplied by the corresponding manufacturer. - Page 9 Gear unit 4.4.1. Oil Lubrication In Standard the gear unit is delivered with the synthetic lubricating oil “Klübersynth GHE 6 – 460” It is lubricated for life, i.e. no oil changes are necessary at all. The oil level should be checked at regular intervals. Sufficient oil is present if when the gear unit is stationary the oil can be seen in the sightglass The lubrication of the cam rollers and the came is thus guaranteed For rotating speed <...

- Page 10 Inspection instructions Inspection Cycle It is recommended to control the oil level approximately every 8000 operation hours in order to avoid any damage of the gear by leakage of oil. 24-Hour Service Immediate availability of important components is guaranteed through stocking of a stand-by set (disk cams, output and cam followers) by the unit operator.

- Page 11 Spare parts installation Remark Please read the following complete text carefully before the disassembly. All construction elements have to be cleaned and to be checked if they are in perfect condition before being installed. The list of spare parts may be helpful for the disassembly and the installation of the individual parts.

- Page 12 • Apply appropriate permanently elastic sealing material upon cleaned sealing surface and install end cap • Move input shaft and check regular movement of mechanism • Fill in oil 6.2.2 Replacing turret ( parallel shaft cam stays built in) • In the case of a defective cam followers shaft bore remove (smaller) tapered roller bearing •...

- Page 13 The height tolerance of the input shaft pivot may not exceed maximum 0,02 mm on the total length of the pivot. An even contact reflection of the cam follower and parallel shaft cam is absolutely required - check with inking past! – •...

-

Page 14: Spare Part Drawing

Spare part drawing BWV_HSP_ E 14 / 16... -

Page 15: Spare And Wearing Parts

Input shaft Output shaft Final remark All repair work requires a certain amount of experience and should therefore be carried out by HEINZ fitters. Address of HEINZ: HEINZ AUTOMATIONS-SYSTEME GmbH Lilienthalstr. 21 64625 Bensheim Tel.: +49 (0)6251 / 1069-0 Fax: +49 (0)6251 / 1069-99 http://: www.heinz-automation.de... - Page 16 Lilienthalstrasse 21 - D-64625 Bensheim Telefon +49(0)6251/1069-0 - Fax +49(0)6251/1069-99 BWV_HSP_ E 16 / 16...

Need help?

Do you have a question about the Basic Series and is the answer not in the manual?

Questions and answers