Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for MASCAR 5100 S

- Page 1 Before starting to use the machine read the instructions...

-

Page 2: Table Of Contents

Wrapper 5100 4.4.2 Reel height setting Errore. Il segnalibro INDEX non è definito. 4.4.3 Reel installation Errore. Il segnalibro SECTION 1 non è definito. Description and main features Errore. Il 4.4.4 Reel use h=500 segnalibro non è definito. Overlaying the film Errore. Il segnalibro Introduction Errore. - Page 3 Wrapper 5100 USE & MAINTENANCE MANUAL - 3 -...

- Page 4 Wrapper 5100 Details indicated on the machine identification plate: Machine model MASCAR authorised service centre to be contacted for technical assistance Serial number Year of manufacture Machine weight USE & MAINTENANCE MANUAL - 4 -...

-

Page 5: Exclusions From Warranty

«5100» Cylindrical Bale Wrapping Machine, hereinafter also referred to as the machine, is 1.1.1 INTENDED USERS OF THE manufactured by MASCAR of Grumolo delle Abbadesse (Vicenza) Italy, hereinafter simply MANUAL referred to as the Manufacturer. This manual is the fundamental instrument for the... -

Page 6: Markings

In the event that the instructions given in this MASCAR «5100» Cylindrical Bale Wrapping manual have not been followed. Machine bears the «CE» mark and complies Neither shall the warranty cover any da... -

Page 7: Use For Which The Machine Is Not

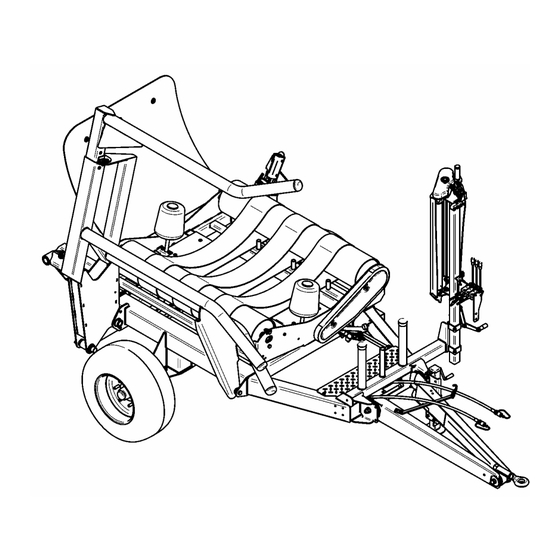

Wrapper 5100 USE FOR WHICH THE MACHINE IS NOT DESIGNED WARNING NOTE: Only if the fork is down it is possible to begin the rotation of the cradle for the DANGER rapping phase. The operator must use the machine in conformity with instructions... - Page 8 Wrapper 5100 fig.1 – View of the machine with its main component assemblies LOAD BEARING CHASSIS ROTATING CRADLE ADJUSTABLE BALE LOADER FORK SIDE ROLLERS CLAMP RELOADING UNIT FILM HOLDING AND CUTTING CLUMP HYDRAULIC DISTRIBUTOR MAT HOLDER DRAWBAR WITH TOW HOOK PLATFORM FOOT SUPPORT FOOT PLATFORM RAFTER...

- Page 9 Wrapper 5100 TECHNICAL DATA 5100 ODEL ALE OUTPUT PER HOUR MAX 30 tours/min AX SPEED CRADLE ROTATION ONTROL NUMBER 12 V LECTRICAL FEEDING 2 Standard + 2 Optional EEL SUPPORT Bale width: 1.2 m IMENSIONS AND WEIGHTS Length 4.81 m Width 2.42 m YDRAULIC...

- Page 10 Wrapper 5100 SECTION 2 WARNING The «WARNING» symbol warns the reader that, if the operations described are not Safety and accident prevention properly performed, this will result in serious bodily injury, death or long-term health SAFETY hazards. The user will have to instruct his/her personnel on the hazards deriving from accidents, on the CAUTION devices fitted for the operator’s safety and on the...

-

Page 11: General Safety Instructions

Wrapper 5100 any modifications may alter the machine’s features and hence compromise operating safety. Therefore, the Manufacturer will not be 2.1.2 GENERAL SAFETY liable for any damages that might be caused INSTRUCTIONS as a result of the use of non-original spare parts. - Page 12 Wrapper 5100 machine, operator can be involved with and that the machine has been correctly possible fatal consequences too. installed and set. Also ensure that all During machine operation, it is strictly components subject to wear or corrosion are forbidden to let any part of your body get near in perfect working condition.

- Page 13 Wrapper 5100 2.1.3 MACHINE CHECKING OPERATIONS CAUTION Occasionally check that all nuts and bolts are correctly tightened. If necessary to tight them again. Use of a torque wrench to set to the following tightening torque settings (in Nm): class Ø 10.9 M 10 M 12...

-

Page 14: Safety Symbols

Wrapper 5100 6) Cod.89005003: Risk of crushing. Fit the additional support chocks when the machine SAFETY SYMBOLS is disconnected from the tractor. (PICTOGRAPHS) 7) Cod.89005004: Danger. allow This machine been designed unauthorised persons near the machine or manufactured by taking all possible measures to its controls during operation. - Page 15 Wrapper 5100 fig. 4 – Safety symbols and their location on the machine. USE & MAINTENANCE MANUAL - 15 -...

- Page 16 Wrapper 5100 fumes which are harmful to man and the environment when burned. CLOTHING WARNING Always wear suitable clothing. Do not wear ties, necklaces or wide or loose clothing, as they could become entangled in the rotating parts. Long hair must be tied up. Always wear safety clothing such as cut- resistant gloves and slip-proof and crush- proof shoes during maintenance and repair...

-

Page 17: General Warnings

Wrapper 5100 Should the machine be taken a long way, it can be loaded on a lorry or freight car. SECTION 3 To this purpose, see paragraph “1.7 Technical data” for weight and dimensions. Dimensions are particularly important in determining the feasibility Moving and transport of transport through tunnels or tight passages. -

Page 18: Transport On Public Roads

Wrapper 5100 WARNING Once the bale wrapper has been transferred onto the lorry or freight car, make sure it is firmly secured in place. The wheels must be secured by wedging suitable chocks under them. Fasten the machine securely to the surface on which it is set, using cables or chains pulled tight and fastened to the hold-down point on the surface and appropriate for the weight of... - Page 19 Wrapper 5100 SECTION 4 4.2.1 CONNECTION TO TRACTOR Instructions for use To ensure a correct connection between bale wrapper and tractor, the following is necessary: position the machine on a level surface. BEFORE USE With the machine on the ground and the support foot holding it in a horizontal position, move the tractor closer and place the tow ring at the right distance from the ground.

- Page 20 Wrapper 5100 PREPARATION OF THE MACHINE FOR USE 4.3.1 HYDRAULIC SYSTEM CONNECTIONS Connect the machine hoses to the tractor's distributor, that must have an hydraulic distributor fitted with a ½” female quick release connector. Connect the hose, with the red plug, with delivery for a single or dual action cylinder, and the hose, with the yellow plug, with a free return.

- Page 21 Wrapper 5100 FILM STRETCHER fig. 11 – Stretching setting fig. 10 - Stendifilm The machine is fitted with a filmstretcher system which unravels and tensions the plastic film. 4.4.1 SETTING THE FILMSTRETCHER fig. 12 – Stretching ratios For successful ensilage, the bales must be The film stretching level depends on the used film wrapped in the best way possible.

-

Page 22: Reel Installation

Wrapper 5100 WARNING Before to transport or to use the machine must to be sure that the screws for the block are tightened. fig. 14 – Reel installation 4.4.4 REEL USE H=500 fig. 13 – Filmstretching height setting To use reel with a height of 500 mm you must to lift the lower plug and use adapter (C, fig.15) on the lower part. - Page 23 Wrapper 5100 fig.17 – Film overlapping The wrapped surface of the bale for every cradle tour has to be set up about the used film height: fig.16 – Film passage with a reel of 750 mm you get a film, that after stretching, has a height of about 600 mm, Note: The filmstretcher is provided with a rolls therefore wrapped surface of the bale for...

- Page 24 Wrapper 5100 The suitable pinion Z24 has installed standard FILM HOLDER/CUTTING CLAMP with the use of reel with a height of 750 mm. For reels with a height of 500 mm to use the The machine has a film holder/cutting clamp (fig. pinion Z16 as indicated in the sticky label (fig.19).

- Page 25 Wrapper 5100 When you begin the new wrapping, after first two cradle tours, an automatic device (rearmament) open the cutting pliers through the lever (F). DANGER It is forbidden to open or close manually the cutting pliers, but it is necessary to execute these operations exclusively through wrapper control.

- Page 26 Wrapper 5100 STEP 2: Wrapping STEP 1: Loading To ensure that the fork is lowered not more than To advance near the bale. 30 cm from the soil and that the rear platform is in To lower loading fork (fig.9, lever A) till about 10 horizontal position.

- Page 27 Wrapper 5100 WARNING DANGER Do not lift cradle before centring of machine. To stop immediately the machine if the bale doesn’t stabilize inside the cradle within the Proceed with unloading operation (fig.9, lever C) two first tours. till the complete lift of the cradle. During this step the cutting pliers closes automatically, with hold An “optional”...

-

Page 28: Maintenance

Wrapper 5100 fig. 28 – Normal unloading fig. 27 – Re-positioning In case of doubts about functioning do not hesitate to contact your area concessionaire for explanations; we remember you that a correct functioning is the better guarantee for life of the machine. -

Page 29: General Instructions

Limited damage to the ensiled product due to mower/conditioners, or rotary presses with accidental film breakages. cutters (e.g. “MASCAR – TUAREG-CUT”) Complete mechanisation of the production Correct proportions of humid and dry material process, requiring very little labour. can improve the product if it is to be used for... -

Page 30: Wrapping Times

Bear in mind that low operating costs and 4.10.6 TIPS FOR BALE WRAPPING prolonged machine lifetime depend on these instructions being followed. MASCAR gives the following advice for using the machine. Regular maintenance of the machine, and in It is in your own interest to carry out... -

Page 31: Every 8 Operating Hours

Wrapper 5100 Apply a coat of rust protection to any worn parts. Repeat the following checks regularly. These checks must be also be carried out at the beginning of each season: DANGER Before to operate on the parts under the cradle, position the safety lock (F) as indicated in fig. - Page 32 Wrapper 5100 5.1.5 EVERY 400 OPERATING HOURS Every 400 operating hours : change rotating cradle angular transmission oil, using 0,8 Kg SAE 90 oil (fig. 34, fig. 33 – Lubrication points of the pliers fig. 31 – Lubrication points fig. 34 – Lubrication points of the cradle fig.

- Page 33 Wrapper 5100 CHECKS AND ADJUSTMENTS 5.2.1 ROTATING CRADLE DRIVE CHAIN Check and set the tension of the cradle drive chain as follows: Remove the side protective case. Lubricate the chain. Check chain tension. For the possibile chain setting, to operate on the tensioner pinion (fig.36, A).

- Page 34 Wrapper 5100 PREPARATION FOR STORAGE WHEN MACHINE IS NOT IN USE At the end of the season, or if the machine is not going to be used for a prolonged period, the following is necessary: Wash the machine with water. Do not point the high pressure jet directly at the roller bearings.

- Page 35 Wrapper 5100 TROUBLESHOOTING TROUBLE CAUSE REMEDY Stretch ratio too high Reduce the stretch ratio Film tensioner rollers blocked Check that roller drive works correctly Damaged film reel Check the state of the film Film tears during stretching Rotation speed too high Reduce the tractor engine rpm Irregularly shaped bale Improve bale shape...

- Page 36 Wrapper 5100 SECTION 7 SECTION 6 Fittings Spare parts COMPUTER MC 300 SPARE PARTS The computer indicates to the operator the end of All the wrapping machine’s components can be wrapping phase. With the MC 300 you could set requested from the Manufacturer by specifying: the wrapped numbers used for a full and complete Machine model dressing.

- Page 38 MASCAR S.p.A. Via Roma, 82 – 36400 Grumolo delle Abbadesse (Vicenza) Italy Tel. +39 0444 380180 – Fax +39 0444 583831 - 380185 E-mail : info@mascar.it Cod. 282.024 rev.0...

Need help?

Do you have a question about the 5100 S and is the answer not in the manual?

Questions and answers