Table of Contents

Advertisement

Operation Manual

LÜTFEN BU KILAVUZU DİKKATLE OKUYUNUZ VE SAKLAYINIZ.

PLEASE READ AND KEEP THIS MANUAL CAREFULLY.

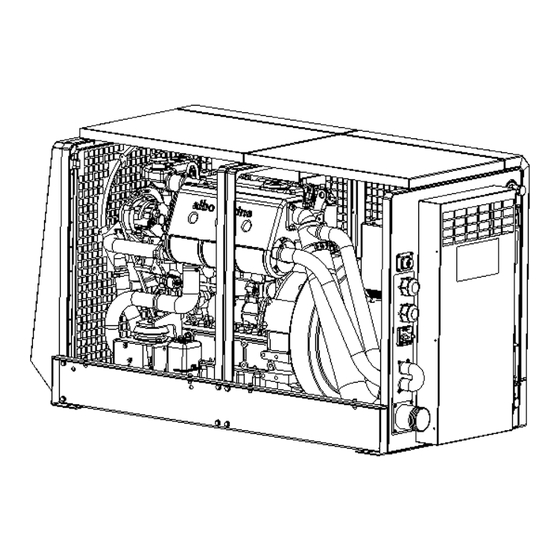

Generator Set

Models

MN 305

MN 307

MS 306

MS 307

MS 310

MS 312

MS 316

MS 323

MS 330

MG 309

TG 306

MG 311

TG 309

MG 314

TG 311

MG 315

TG 314

MG 320

TG 315

MG 323

TG 316

MG 330

TG 320

TG 323

TG 330

TG 343

TN 307

TS 309

TS 315

TS 320

TS 323

TS 330

TS 343

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Albo marine MN 305

- Page 1 Operation Manual Generator Set Models MN 305 TN 307 MG 309 TG 306 MN 307 TS 309 MG 311 TG 309 MS 306 TS 315 MG 314 TG 311 MS 307 TS 320 MG 315 TG 314 MS 310 MG 320...

- Page 2 Product identification information : …………………..…… Model Serial No : ……………………..… Altınboğa Mak.San.Tic. A.Ş. Maltepe Mah.Hastane Yolu Demirciler Çarşısı 1.Baltaş San. Sitesi No:10/37 Zeytinburnu / İSTANBUL Telephone + 90 212 612 25 00 / + 90 212 612 00 48 : http://www.altinboga.com http://www.albomarine.com E-mail : altinboga@altinboga.com...

-

Page 3: Table Of Contents

Contents 1. SAFETY PRECAUTIONS ................1–1 OPERATION MANUAL 2. INTRODUCTION ....................2–1 About this Manual ....................2–1 Product Identification Label ................2–1 Technical Services ....................2–1 3. CONTROL SYSTEMS ..................3–1 Manuel Control Panel ..................3–1 Electronic Remote Control Panel ..............3–2 Albomarine DKG 114 Electronic Remote Control Module ....... - Page 5 1.SAFETY PRECAUTIONS Always read the MAINTENANCE – GENERATOR VOLTAGE IS LETHAL OPERATION AND USER’S MANUAL carefully before operating the generator set. The All power, control cables and connecting generator set that you have purchased may elements that will be connected externally to the operate safely and reach its performance generator shall be connected by a trained and when the proper operating conditions...

- Page 6 DENSE FUEL VAPOR IN CLOSED AREAS MAY CAUSE DIESEL ENGINE OVERSPEED RUNNING Always perform necessary checks before starting Check all connection elements and to operate the generator. Never operate your ensure that they are not loose. generator when there is a fuel seepage, gobbing, Do not work on the generator when you leak or dense fuel vapor in closed areas.

-

Page 7: Introduction

2.Introduction Product identification label informations ABOUT THIS MANUAL This manual is operating, utilization and maintenance for generator models listed on the front cover. All users who have purchased these products shall carefully read and understand this Yedek Parça Model Parça No PERÝ... -

Page 8: Control Systems

3.Control Systems Manual control panels are come into service as standard with the generator set to control operating conditions and status of the generator set. Optionally, an electronic remote control module may also be provided according to the requirements of the user. MANUAL CONTROL PANEL (Figure 2) Manual control panel has an engine oil pressure gauge, engine coolant temperature gauge,... -

Page 9: Albomarine Dkg 114 Electronic Remote Control Module

ALBOMARINE DKG 114 ELECTRONIC REMOTE CONTROL MODULE Perform necessary maintenance and checks before operating the generator set absolutely. DKG 114 electronic module is a microprocessor controlled device that allows both manual and remote control of the generator set. Device is completely cutout and current taken from the battery is zero in stop position. - Page 10 Failure Signals If the generator set fails, and stop due to this failure,the malfunction lamp lights up because the signal comes from the indicator of failure part and displays the description of fault. After repairing breakdown, it extinguish with reworking generator. Faults, causes and explanations about the failure to eliminate FAULT AND SOLVING PROBLEMS (Page 6-1 and counting), please refer to.

-

Page 11: Operation

4.Operation FUEL SPECIFICATIONS ULSD (ULTRA LOW SULFUR DIESEL) Diesel : Diesel fuel is a flammable fuel with low sulfur grade; diesel fuel that substance. As a result of uncontrolled contains sulfur amount lower than 15 ppm or ignition or combustion of the fuel may cause lower than 0.0015% of its total weight. -

Page 12: Engine Oil

ENGINE OIL Use at high quality engine oils. Make selections Check whether the output hose of proper the following specifications with the diesel the extinguisher to be used in a fire is engine lubrications oils. You can obtain high matching the marked hole in advance. performance from your engine in this way. -

Page 13: Pre-Operation Checks

PRE-OPERATION CHECKS OPERATING THE GENERATOR SET Generator set may operate or stop by a manual control panel or an electronic remote control : Exhaust gas is lethal. The exhaust panel. of all engines contains carbon monoxide (CO); this odorless, colorless and poisonous Operating the Generator Set By the Manual gas cause unconsciousness and death in a Control Panel... -

Page 14: Emergency Stop

Stopping the Generator Set Another important point in generator selection is Turn off all electrical loads before stopping the that the sum of the instantaneous current load generator. Generator set shall be operated for 2 values of the equipment that will be operated in minutes with no load, then press the “STOP”... -

Page 15: Circuit Breaking Fuses

NO-LOAD OPERATION Minimize the no-load idle operation time of the 12 V DC Fuse generator as much as possible. Fuel may not ignite efficiently during the initial start as the engine is cold. This may cause excessive smoke in the exhaust. Load value that the generator may operate most efficiently is between 25% and 75%. -

Page 16: Stand By Operation Of The Generator Set

STAND BY OPERATION OF THE 4. Drain the coolant in Engine Coolant GENERATOR SET Exchanger, siphon kit and muffler if the generator will have freezing Operate your generator set with a load rate of 25 temperatures. 5. Turn off all fuses in the generator set. to 75% for 1 hour per month. -

Page 17: Periodical Maintenance

5. Periodical Maintenance It is possible to obtain best performance and Generator sets that cannot provide these efficiency that will allow it operates for a long conditions shall be considered out of warranty time from your generator set if the periodical cover. -

Page 18: General Maintenance

: Inadvertent or remote operation : Do not smoke in inadequately of the engine during maintenance and repair ventilated areas where fuel vapors may have work may cause personal injuries or death. and do not turn the electrical switches in these Therefore, disconnect battery negative (-) areas on/off. -

Page 19: Maintenance Of The Battery And Battery Connections

MAINTENANCE OF THE BATTERY AND REPLACEMENT OF ENGINE OIL AND FILTER BATTERY CONNECTIONS Refer to the periodical maintenance chart for regular engine oil replacement. (Page 5-1) Operate the generator set until it reaches the : Stop the generator before starting proper operating temperature. -

Page 20: Replacing Fuel Filter

Prevent the fuel system from ingress of dirt, water and other foreign materials. Cleaning the water and residues: Generator set may have a fuel filter with water-fuel separator. Check the fuel filters with water-fuel separator for water build-up. If the fuel quality is low and condensation is inevitable, drain water and residues more times than it is scheduled. - Page 21 PUMP FUEL FILTER OIL DIPSTICK FIGURE 9. FUEL FILTER OIL FILTER AND SERVICE POINTS - MN 305, MS 306, MN 307, MS 307, MG 309, TG 309 FUEL FILTER FIGURE 10. FUEL FILTER OIL FILTER AND SERVICE POINTS - MN 305, MS 306, MN 307, MS 307...

- Page 22 FIGURE 11. FUEL FILTER OIL FILTER AND SERVICE POINTS - MS 312 , MS 316, MS 323, MG 314, MG 315, MG 320, MG 323 , TG 314 , TG 315 , TG 320 , TG 323, TS 312 , TS 315 , TS 320 , TS 323 albo marine MANUAL OIL PUMP ( OPTIONAL ) FIGURE 12.

- Page 23 FUEL FILTER MANUAL OIL PUMP FUEL FILTER OIL FILLING OIL DIPSTICK ( OPTIONAL ) COVER FIGURE 13. FUEL FILTER OIL FILTER AND SERVICE POINTS - MG 330, MS 330, TG 330, TS 330 FUEL FILTER OIL FILLING COVER OIL DRAIN HOSE FUEL FILTER OIL DIPSTICK FIGURE 14.

- Page 24 MAINTENANCE OF ENGINE COOLING SYSTEM Engine Coolant Expansion tank is designed to Refer to the periodical maintenance chart. keep coolant level inside the engine fixed during ( Page 5-1 -Table 2 ). Perform necessary the operation. Lack of coolant inside the engine interventions in the intervals specified in the chart.

- Page 25 : Filling a cold coolant to the hot If the engine continues to stop, clean the heat engine may cause cracks on the manifold, exchanger pipes and covers. If there is a body and block. Always follow freezing danger, drain the heat exchanger when manufacturer’s instructions for this type of the generator set is not operated or stored.

- Page 26 Elbow Temperature Zinc (anode) Switch Exhaust Temperature Switch Exhaust Gas Sea Water Outlet Hose Sea Water Coolant FIGURE 15. ENGINE COOLING SYSTEM - MN 305, MS 306, MS 307, MS 310, TS 307, TS 310, TG 307, TG 311 5–10...

- Page 27 Sea Water Sea Water Outlet Pipe Inlet Hose to Pump Sea Water Coolant FIGURE 16. ENGINE COOLING SYSTEM (COOLER, SEA WATER PUMP, HOSES) MN 305, MS 306, MS 307, MS 310, TS 307, TS 310, TG 307, TG 311 5–11...

- Page 28 Coolant Filler Hot Water Elbow Sea Water Pump Sea Water Inlet Hose to Pump Exhaust Gas Sea Water Elbow Zinc (Anode) Exhaust Temperature Switch Exhaust Gas Sea Water Outlet Hose Coolant Sea Water Drain Tap Coolant FIGURE 17. ENGINE COOLING SYSTEM - N 307, MG 307 , MG 309, TG 309 MS 307, TS 307 5–12...

- Page 29 Coolant Cooler Filler Cap (Engine Coolant Tank) Sea Water Engine Exchanger Zinc (Anode) Hot Water Outlet Hose Elbow Exhaust Gas Sea Water Elbow Exhaust Temperature Switch Exhaust Gas Sea Water Hose Sea Water Pump Exhaust Gas Sea Water Sea Water Inlet Hose Outlet to Pump...

- Page 30 Cooler Coolant Filler Cap Thermostat Housing Sea Water Pump Sea Water Inlet Hose Coolant Drain Tap to Pump Sea Water Exchanger Outlet Hose Exhaust Temperature Switch Exhaust Gas Sea Water Elbow Exhaust Gas Sea Water Outlet Hose Zinc (Anode) Sea Water Coolant FIGURE 19.

- Page 31 Coolant Cooler (Engine Coolant Tank) Filler Cap Engine Hot Water Elbow Exhaust Gas Sea Water Elbow Exhaust Temperature Switch Siphon Kit Elbow (Anode) Zinc Sea Water Pump Sea Water Inlet Opening Exhaust Gas Sea Water Outlet Opening Sea Water Coolant FIGURE 20.

- Page 32 Cooler (Engine Coolant Tank) Coolant Filler Cap Engine Hot Water Elbow Sea Water Pump Sea Water Inlet Hose to Pump Sea Water Heat Exhaust Exchanger Outlet Hose Zinc (Anode) Seawater Elbow Exhaust Temperature Switch Exhaust Gas Sea Water Outlet Hose Sea Water Coolant FIGURE 21.

- Page 33 Sea Water Exchanger Outlet Hose Coolant Filler Cap Engine Hot Cooler Water Elbow (Engine Coolant Tank) Exhaust Temperature Switch Siphon Kit Elbow Zinc (Anode) Sea Water Spout Sea Water Pump Sea Water Heat Exhaust Gas Exchanger Outlet Seawater out Hose mouth Sea Water Inlet Hose to Pump...

- Page 34 Cooler (Engine Coolant Tank) Coolant Filler Cap Engine Hot Water Elbow Sea Water Pump Sea Water Inlet Hose to Pump Sea Water Exhaust Sea Water Exchanger Exit Temperature Exchanger Outlet Switch Zinc (Anode) Exhaust Gas Sea Water Sea Water Hose Coolant FIGURE 23.

- Page 35 Always disconnect battery terminals before working on the engine. Always MN 305 - MS 306- MG 309 – TG 309 -MS 307 - MS 309 – disconnect the negative (-) battery cable MS 310 - MG 310 - MS 315 – TG 307 - TG 310 - TG 315...

- Page 36 Adjustment of V-Belt Tension 6. Tighten the adjustment bolts, install the belt Replace and check the component in the guide and protection covers. Connect intervals specified in Periodical maintenance battery terminal cables (negative (-) cable chart (Page 5-1) (Table 2). Replace and check last) and operate the generator set.

- Page 37 Replacement of the Thermostat 1. Top-up the engine coolant (ethylene Replace and check the component in the glycol – distilled water) lost during the intervals specified in Periodical maintenance maintenance and repair operation in a chart (Page 5-1, Table 2). Replace and check proper way.

-

Page 38: Diagnosis With Electronic Remote Control Panel

6. Troubleshooting and Problem Use the generator set control panel for Depending on the features of the electronic troubleshooting any faults or problems. card module is used error source related with (Table 3) Always apply the following corrective the section that is the source of the fault or and preventive measures while troubleshooting. - Page 39 TABLE 3. TROUBLESHOOTING AND GENERATOR SET FAULTS Fault-Problem Possible reasons Remedies Check oil level. Ensure that it is Not applicable engine oil level Oil pressure lamp is turned in proper level. (it may be low or high) on. Low oil pressure ...

- Page 40 TABLE 3. TROUBLESHOOTING AND GENERATOR SET FAULTS Fault-Problem Possible reasons Remedies Open the sea water intake tap. Sea water inlet is closed Clean the filter system, and remove the blockage. Always fill Sea water filter system is clogged the filter with water before operating...

- Page 41 TABLE 3. TROUBLESHOOTING AND GENERATOR SET FAULTS (Continued) Fault-Problem Possible reasons Remedies Check and replace the circuit Circuit breaking fuse error breaking fuse Repair fuel leaks in the fuel system There may be a fault on the fuel and remove air bubbles remaining system Speed lamp is turned on.

- Page 42 TABLE 3. TROUBLESHOOTING AND GENERATOR SET FAULTS (Continued) Fault-Problem Possible reasons Remedies Repair fuel leaks in the fuel system and remove air bubbles remaining Leakage in fuel system in the system. Speed alarm lamp is Check the connection points to ...

- Page 43 TABLE 3. TROUBLESHOOTING AND GENERATOR SET FAULTS (Continued) Fault-Problem Possible reasons Remedies Immediately take everyone to Carbon monoxide detector open air. Ensure proper There may be excessive carbon gives a warning signal ventilation. Seek medical monoxide build-up inside the vessel assistance when required ...

Need help?

Do you have a question about the MN 305 and is the answer not in the manual?

Questions and answers