Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Datron neo

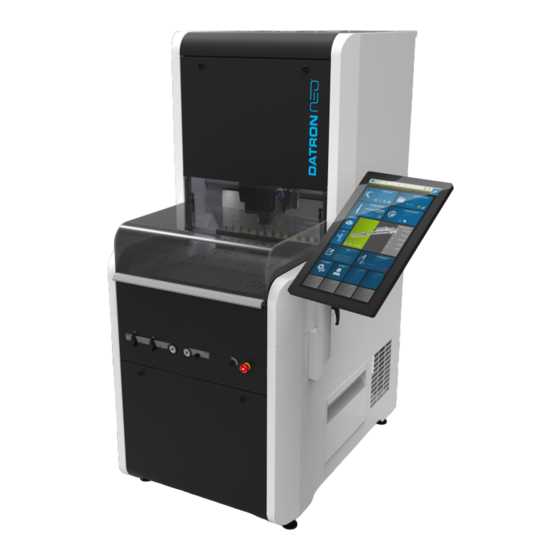

- Page 1 DATRON neo Setup instructions...

- Page 2 It is not permitted to distribute or copy these operating instructions, or to utilize or communicate their contents, without the ex- press permission of DATRON AG. All rights regarding the registration of patents, utility models or registered designs remain re-...

-

Page 3: Table Of Contents

4 Safety regulations for operating the machine............4-1 4.1 Dry machining...........................4-1 4.2 Processing with minimum-quantity cooling lubrication system..........4-2 4.3 Use of ethanol as cooling lubricant....................4-3 4.4 Safety instructions for cleaning...................... 4-4 5 Vacuum cleaner (optional)..................5-1 6 Checklist........................6-1 Setup instructions neo DATRON AG 1.21... - Page 4 Contents DATRON AG Setup instructions neo 1.21...

-

Page 5: Setting Up The Machine

Flammable vapours may be generated when using cooling lubricants. CAUTION Open flames, smoking, eating and drinking are prohibited in the vicinity of the machine. The safety instructions of the manufacturer of the cooling lubricant and material must be observed! Setup instructions neo DATRON AG 1.21... -

Page 6: Room Climate

18 °C, ideal would be 25 °C. If there is a risk of frost during storage or transport of the DATRON machine, the cooling water must be completely drained out of the machine and the cooling device beforehand. -

Page 7: Screen

(e. g. with a vacuum plate). Screen Screen Possible damage to the screen! Covering the screen leads to excessive heat development. CAUTION Never cover the screen during operation. Keep ventilation slots free. Setup instructions neo DATRON AG 1.21... - Page 8 Setting up the machine Screen DATRON AG Setup instructions neo 1.21...

-

Page 9: Connecting The Supply Media

Danger of injury and death due to high voltage! Work on electrical devices requires technical knowledge, otherwise there is a risk of injury and death by electrocution. WARNING Electrical work must be performed by qualified electricians. Setup instructions neo DATRON AG 1.21... -

Page 10: Internet Connection

An Internet connection for the control computer integrated in the machine is absolutely necessary to be able to make use of remote maintenance. This is the only way DATRON can access the machine control if support is needed, making immediate analysis and help possible. - Page 11 Connecting the supply media Network integration Fig. 2-2: Integration of the DATRON computer in a company network Control computer of the DATRON machine USB port at the control computer Hardware firewall Company network The establishment of a network connection (internet, in-house data exchange) must be made without changing the configuration of the control computer (for instance, integration into a domain).

-

Page 12: Notes Regarding The Control Computer

Observe the following points to ensure the process reliability of the machining system and quick help in the event repairs are needed: The DATRON machine may only be operated with the control components included in delivery. These are an integral part of the system. -

Page 13: Cooling Lubricant

Compressor Design your compressed air supply so that there is a continuous supply available to the DATRON machine. Depending on the type of compressor, the capacity must lie much higher than the consumption of the machine and the supply buffered via a boiler, so that the compressor has sufficient cooling-off time available. - Page 14 Impermissible cooling lubricants Do not use any drilling emulsions, cooling lubricants with high solid content or such which tend to flocculate (milky emulsion). The DATRON machine is not designed for such cooling lubricants and potential material damage could result. If this is not observed, it will invalidate the warranty.

-

Page 15: Chip Suction

Connecting the supply media Chip suction Chip suction Only use suctioning systems which are permitted for the material to be machined. Setup instructions neo DATRON AG 1.21... - Page 16 Connecting the supply media Chip suction DATRON AG Setup instructions neo 1.21...

-

Page 17: Technical Data

Operating terminal Distance 700/980 Support feet Extension length right Chip tray Traverse path (X/Y/Z) 520/420/230 Machining traverse paths Height Portal access Transport dimensions when packed in wrapping width/depth/height 980/1480/2160 on the pallet (terminal mounted) Setup instructions neo DATRON AG 1.21... - Page 18 Technical data Dimensions and weight 1000 1290 1296 2275 Fig. 3-1: Machine dimensions DATRON AG Setup instructions neo 1.21...

-

Page 19: Safety Regulations For Operating The Machine

Machine damage due to released dusts! During machining, the dusts that are released have to be suctioned off by a suitable vacuum cleaner. CAUTION Check the compatibility of the vacuum cleaner and the material to be machined. Setup instructions neo DATRON AG 1.21... -

Page 20: Processing With Minimum-Quantity Cooling Lubrication System

If in doubt, consult a safety professional. Canisters with cooling lubricants must be labelled. Only use the cooling lubricants recommended by DATRON, since these are optimally suited for the system. Non- recommended cooling lubricants can lead to poor results and damage of the machine. -

Page 21: Use Of Ethanol As Cooling Lubricant

Only use extraction equipment which is suitable for extracting swarf from the material to be machined. Cleaning When you clean the machine, wait until the ethanol has evaporated and use a vacuum cleaner which is free of ignition sources. Setup instructions neo DATRON AG 1.21... -

Page 22: Safety Instructions For Cleaning

Empty the chip tray regularly, no later than when it is more than half-full. Observe the information regarding cleaning in the operating instructions of the machine. DATRON AG Setup instructions neo 1.21... -

Page 23: Vacuum Cleaner (Optional)

544 x 456 x 600 Dimensions LxWxH (mm) 40 kg Weight 1.1 kW Power 100-230V Voltage 2100 Pa Negative pressure 285 m³/h Air output max. <66 dB(A) Sound level 18 l Volume Filter category Setup instructions neo DATRON AG 1.21... - Page 24 Vacuum cleaner (optional) DATRON AG Setup instructions neo 1.21...

-

Page 25: Checklist

The following checklist provides an overview and summary of all necessary preparatory work for setting up a DATRON machine. The items point out the individual steps. For exact details, please refer to the respective chapter. Using this checklist, please check whether everything is ready for bringing the machines in to you.

Need help?

Do you have a question about the neo and is the answer not in the manual?

Questions and answers