Summary of Contents for Roto-Jet 2200

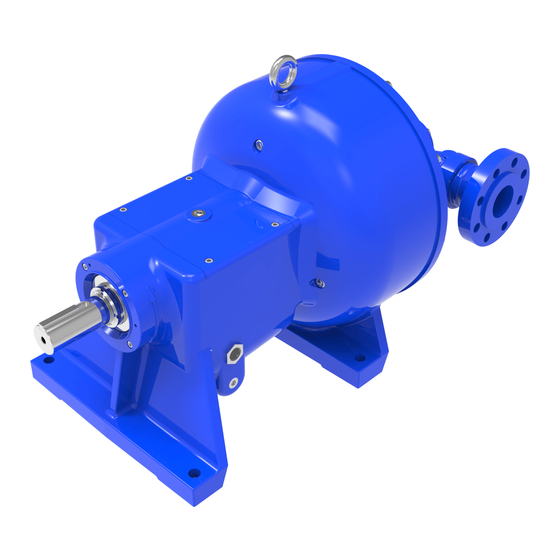

- Page 1 Excellent Engineering Solutions Threaded Flanged Disassembly/Assembly Manual Model 2200 RJ-DA-15 07/19...

-

Page 2: Table Of Contents

ROTO-JET PUMP DISASSEMBLY/ASSEMBLY Model 2200 Table of Contents INTRODUCTION ........................ 1 1.1. ROTO-JET PUMP DESIGN ..................1 1.2. PUMP IDENTIFICATION ..................... 1 DISASSEMBLY/ASSEMBLY REFERENCE INFORMATION ..........2 2.1. TOOLS AND ASSEMBLY STANDS ................2 2.2. DIMENSIONAL DRAWINGS ..................5 2.3. - Page 3 ROTO-JET PUMP DISASSEMBLY/ASSEMBLY Model 2200 Table of Contents 4.4. ROTOR ASSEMBLY INSTALLATION ............... 24 4.5. SEAL INSTALLATION ....................24 4.5.1. 2-7/8” Type S Single Seal .................. 24 4.5.2. 3-1/2” Type SD Single/Double Seal ..............25 4.5.3. Seal Hub Replacement (Reference Figure 2-9) – 3-1/2” Seal Only ....26 4.6.

-

Page 4: Introduction

Roto-Jet pumps are designated by a series of letters and numbers, such as 2200B-S484. The first group, 2200A or 2200 B, designates the drive end radial bearing design. “A” is for direct drive applications and “B” is for belt drive applications. The 2200 is an indication of the basic mechanical configuration and the second group, S484, designates the pick-up tube inlet size. -

Page 5: Disassembly/Assembly Reference Information

Roto-Jet pumps offers assembly stands for mounting the unit during disassembly and assembly. - Page 6 Legs, Puller – 22-1/2” 1 Pr. 060095056 ACCESSORIES* Assembly Stand-Pump Kit (Includes stand & swivel hoist 060580652- ring) Assembly Stand-Rotor 060581074 0664076-01 0665198 Ring, Swivel Hoist (D-Ring) 0667025 *Note: Accessories are not included with special tools or purchased tools must be ordered. 2200...

- Page 7 CAUTION When lifting the pump into the vertical position with or without the assembly stand a swivel hoist ring shall be used in place of the lifting eye bolt. Figure 2-1: Disassembly/Assembly Stands 2200...

-

Page 8: Dimensional Drawings

2.2. DIMENSIONAL DRAWINGS Figure 2-2: 2200 2x2 Dimensional Drawing 2200... - Page 9 Figure 2-3: 2200 3x2 Dimensional Drawing (Threaded) 2200...

- Page 10 Figure 2-4: 2200 3x2 Dimensional Drawing (Flanged) 2200...

-

Page 11: Sectional Drawing And Parts Lists

2.3. SECTIONAL DRAWING AND PARTS LISTS TORQUE TABLE ITEM NO. Ft/Lbs N.M. Figure 2-5: 2200 2x2 Section Drawing 2200... - Page 12 TORQUE TABLE ITEM NO. Ft/Lbs N.M. Figure 2-6: 2200 3x2 Section Drawing 2200...

- Page 13 Table 2-2: Parts List - 2200 Pump ITEM QTY. DESCRIPTION PART NUMBER Pick-Up Tube Kit (see Notes 1 and 3) S-266 17-4 PH 0665156-KIT D-266 17-4 PH 0665280-KIT S-375 17-4 PH 0664951-1KIT D-375 17-4 PH 0665281-KIT S-484 17-4 PH 0664949-1KIT...

- Page 14 Notes: (1) Standard Units are 17-4 PH. Contact factory representative for optional metallurgy. (2) Item 93 is supplied in pumps with single type S seals with a seal flush. (3) Pick-Up Tube kits include the pick-up tube and friction ring (Item 145). 2200...

- Page 15 Figure 2-7: 2200 Rotor Assembly Section Drawing 2200...

- Page 16 Table 2-3: Parts List - Rotor Assembly ITEM QTY. DESCRIPTION PART 2200 2200A 2200B BARE STACKED STACKED BALANCED BALANCED BALANCED Rotor-Ductile Iron 0665137 Rotor-SST 0665137-1 Rotor Cover 2-7/8” Type S Single Seal, DI 0664862-1 2-7/8” Type S Single Seal, 316 SST 0664862-2 3-1/2”...

-

Page 17: Mechanical Seals And Parts List

Seal Kit - Pusher - SC vs. SC 0664975-02 Consisting of: Seal - Pusher - Carbon 0664941 Seal - Pusher - Silicon Carbide 0665260 Mating Ring - Tungsten Carbide 0664942 Mating Ring - Silicon Carbide 0665733 O-ring, PUT 41396 Pin, Anti-rotation 0665302 O-ring, PUT Nut 58218 2200... - Page 18 Consisting Of: ITEM QTY. DESCRIPTION PART NUMBER O-ring, Seal 060083941 O-ring, PUT 41396 O-ring, Manifold 060083913 O-ring, Mating Ring 060083940 Seal, Pusher, Carbon 060087015W Seal Mating Ring 0665904 Retaining Ring 0665293 Pin, Mating Ring 178022 O-ring, PUT Nut 58218 2200...

-

Page 19: Seal Shimming

The seal height measurement is then subtracted from the number stamped on the measuring bar. This will give you dimension “B”. Referring to the shim chart and the box in which the measured value “B” falls. (The shimming chart is based on shims .015” thick, actual thickness may vary.) 2200... - Page 20 The seal height measurement is then subtracted from the number stamped on the measuring bar. This will give you dimension “B”. Referring to the shim chart and the box in which the measured value “B” falls. (The shimming chart is based on shims .015” thick, actual thickness may vary.) 2200...

-

Page 21: Disassembly Instructions

DISASSEMBLY INSTRUCTIONS To disassemble the Roto-Jet pump, refer to Section 2.3. The following instructions are applicable to the pump being removed from its foundation and placed securely into a vertical position in which the pump shaft is pointed downward and the endbell is facing up. -

Page 22: Seal Removal

Section 4.5 for reassembly of seal. 3.3.2. 3-1/2” Type SD Single/Double Seal 3.3.2.1 Remove four socket head cap screws (61) from the manifold plug (33). Remove the manifold plug. If pump has a threaded manifold, skip this step and proceed to 3.3.2.2. 2200... -

Page 23: Rotor Assembly Removal

Remove two of the twelve endbell socket head cap screws (63) at nine o’clock and three o’clock. Install the two endbell alignment rods (P/N 060580573) in place of the two cap screws. Remove the remainder of the socket head cap screws (63). Thread eyebolts (P/N 060055411) into 2200... -

Page 24: Rotor Cover And Pick-Up Tube Removal

Install one 5/8” eye bolt into the end of the shaft. 3.6.5 Thread three cap screws into three jackscrew holes hand tight. 3.6.6 Lift rotor assembly and with rotor end down and shaft up, place rotor assembly on assembly stand, being sure that the head of each socket 2200... -

Page 25: Pedestal Sleeve Removal

8. This also applies if wear is present in the rotor or rotor cover. 4.1. BEARING INSTALLATION 4.1.1 Install plug (133) and o-ring (134) in rotor. Install two guide pins (P/N 0661975) into rotor for shaft alignment. Heat the drive shaft bore in the 2200... -

Page 26: Pedestal Sleeve Installation

Press or freeze pedestal bushing (100) using liquid nitrogen and install all the way into the bore of the pedestal (17) with the step towards the back. The face of the sleeve must be parallel to the face of the pedestal end plate machined surface to within .001 inches. 2200... -

Page 27: Rotor Cover Installation

SEAL INSTALLATION 4.5.1. 2-7/8” Type S Single Seal 4.5.1.1 Lubricate and install seal mating ring o-ring in the hub of the rotor cover (4). Align the drive pin with the hole in the mating ring and insert the seal 2200... -

Page 28: 3-1/2" Type Sd Single/Double Seal

4.5.1.6 Install alignment tools (P/N 0661975) in rotor case for endbell/rotor case/pedestal alignment. Align endbell so that the Roto-Jet name is at the top. Carefully slide the endbell (26) into place. Lubricate and install the twelve endbell socket head cap screws (63) and torque to 104 ft. lbs. -

Page 29: Seal Hub Replacement (Reference Figure 2-9) - 3-1/2" Seal Only

4.6.1 Lubricate and install pick-up tube o-ring (49) and pick-up tube nut o-ring (127) into the pick-up tube (1). 4.6.2 Install two pick-up tube alignment pins (128) into the pick-up tube (1) and friction ring (145)(P/N 0666227). 2200... - Page 30 Note (2): Always inspect pick-up tube nut for any damaged threads or scratches, replace if necessary. Remember the pick-up tube nut has left-handed threads. 4.6.8 Thread in four ¾” socket head cap screws (32) and torque to 240 ft. lbs. 2200...

- Page 31 Be sure that the slinger just touches the bearing cap or the bearings may overheat. 4.6.12 Rotate the driveshaft 360 degrees to make sure that the rotating assembly moves freely. 4.6.13 The pump can now be returned to service. 2200...

-

Page 32: Rotating Component Replacement

Torque the cap screws to 68 ft. lbs. 7.2 Completely fill rotor cavity with liquid of required specific gravity. Seal off. 7.3 Position half key in shaft and securely tape to shaft. 2200... -

Page 33: Parts

0664975-01 Seal Kit – Double Seal – Pusher Non-Abrasive Service 3-1/2” Carbon vs. 0665290 0665290-02 Abrasive Service 3-1/2” TC vs. TC Seal Kit – Double Seal – Bellows Non-Abrasive Service 3-1/2” Carbon vs. 0665291 Pick-up Tube Replacement Kit 0665213 2200... - Page 34 Table 8-2: Auxiliary Equipment - Bypass Orifice ITEM PART NO. Orifice – 3/32” 0682444 Orifice – 1/8” 0682445 Orifice – 5/32” 0682446 2200...

-

Page 35: Ordering Parts

8.2. ORDERING PARTS 8.2.1 General – It is Roto-Jet Pump’s policy to continually improve its products. Therefore, specifications are subject to change without notice. Parts should be ordered as far in advance of their use as possible since circumstances beyond our control may reduce existing stock. -

Page 36: Maintenance Record

MAINTENANCE RECORD DATE SERIAL NO. MAINTENANCE RECORD 2200... - Page 37 Appendix A A.1 2200 Rotor Assembly Drive Conversion. (Reference Figure 2-7) A.2 Preparation. Remove rotor assembly per Section 3.4. A.3 Convert from 2200B (belt drive) to 2200A (direct drive). A.3.1 Remove self-locking nut (46) using a bearing locknut wrench adapter. Discard nut.

- Page 38 A.4.3 Heat the inner race of the roller bearing (13B) to 150°-175° F, and place it on the shaft against the bearing spacer set (23). Place the outer race and rollers in position over the inner race (13B). 2200...

- Page 39 Appendix B When using the swivel hoist, use in place of this lifting eye. Figure B-1: Alignment Tool Locations – 2x2 2200...

- Page 40 Figure B-2: Alignment Tool Location – 3x2 Pump 2200...

- Page 41 For optimum service and technical assistance, please contact our factory for the distributor or representative nearest to your project: Weir Specialty Pumps 440 West 800 South Salt Lake City, UT 84101 (P.O. Box 209, 84110-0209) Tel 801-359-8731 Fax 801-530-7828 info@weirsp.com www.weirpowerindustrial.com Excellent Engineering...

Need help?

Do you have a question about the 2200 and is the answer not in the manual?

Questions and answers