Table of Contents

Advertisement

Quick Links

Application Notes

1 Scope

These application notes are a guide to applying the

G123-817-006 LVDT Oscillator Demodulator. The following is a

summary of the process that these application notes apply to:

• Select the LVDT you will use.

• Determine the required oscillator level and frequency.

• Wire a test unit for performance checking.

• O ptimise performance on the test unit by adjusting oscillator

level, oscillator frequency, phase, output span and output

zero.

• Apply your design.

The G123-817-006 is not a "plug and play" device. It needs to

be carefully optimised for the particular LVDT being used.

LVDT selection criteria and closed loop considerations are not

covered by these application notes.

2 Description

The G123-817-006 is a general purpose LVDT oscillator

demodulator that can be configured to suit a wide variety of

series opposed (4 wire) LVDTs. To produce optimum results,

a knowledge of the characteristics of the LVDT being used is

required.

For a more detailed description refer also to data sheet

G123-817.

The G123-817-006 is an improved version of the

G123-817-002. It does not have a 3.5/8.0V oscillator selector

switch and has improved common mode noise rejection.

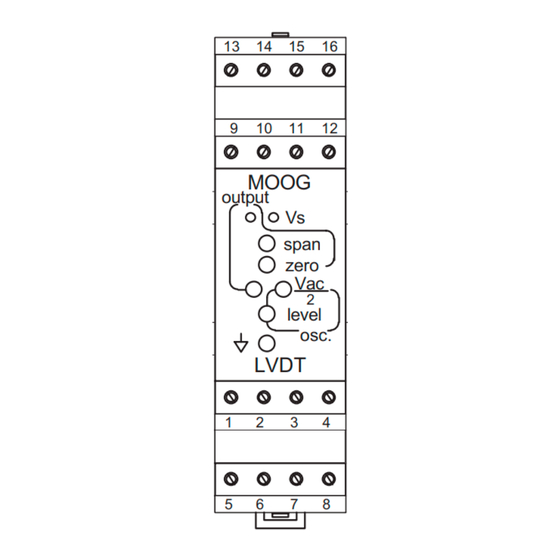

3 Installation

3.1 Placement

A horizontal DIN rail, mounted on the vertical rear surface of

an industrial steel enclosure, is the intended method of

mounting. The rail release clip of the G123-817-006 should

face down, so the front panel and terminal identifications are

readable and so the internal electronics receive a cooling

airflow. An important consideration for the placement of the

module is electro magnetic interference (EMI) from other

equipment in the enclosure. For instance, VF and AC servo

drives can produce high levels of EMI. Always check the

EMC compliance of other equipment before placing the

G123-817-006 close by.

3.2 Cooling

Vents in the top and bottom sides of the G123-817-006 case

provide cooling for the electronics inside. These vents should

be left clear. It is important to ensure that equipment below

does not produce hot exhaust air that heats up the

G123-817-006.

LVDT Oscillator Demodulator

Top vents

13

9

output

1

5

Bottom

vents

3.3 Wiring

The use of crimp "boot lace ferrules" is recommended for the

screw terminals. Allow sufficient cable length so the circuit

card can be withdrawn from its case with the wires still

connected. This enables switch changes and pot adjustments

on the circuit card to be made while the card is still connected

and operating. An extra 100mm for cables going outside the

enclosure, as well as for wires connecting to adjacent DIN rail

units, is adequate. The LVDT cable should be 3 twisted pairs

with an overall screen.

Enclosure

Grounded EMI

cable gland

Cable

Radial screen

termination

Preferred wiring

G123-817-006

Cover

release

tab (2)

Screw

terminals

9 - 16

14

15

16

10

11

12

DIN rail

MOOG

Vs

span

zero

Vac

2

level

osc.

LVDT

2

3

4

Screw

6

7

8

terminals

1 - 8

DIN rail

release

clip

Cooling

airflow

Wires

100mm Loop

Page 1 of 4: C70880 Rev E – 11.15

Advertisement

Table of Contents

Summary of Contents for Moog G123-817-006

- Page 1 3 Installation on the circuit card to be made while the card is still connected and operating. An extra 100mm for cables going outside the 3.1 Placement enclosure, as well as for wires connecting to adjacent DIN rail units, is adequate. The LVDT cable should be 3 twisted pairs A horizontal DIN rail, mounted on the vertical rear surface of with an overall screen. an industrial steel enclosure, is the intended method of mounting. The rail release clip of the G123-817-006 should Enclosure Wires face down, so the front panel and terminal identifications are readable and so the internal electronics receive a cooling Grounded EMI airflow. An important consideration for the placement of the cable gland module is electro magnetic interference (EMI) from other 100mm Loop equipment in the enclosure. For instance, VF and AC servo drives can produce high levels of EMI. Always check the EMC compliance of other equipment before placing the G123-817-006 close by.

- Page 2 Vac and circuit card TP2. Set an oscillator level The accepted method is to radially terminate the cable screens, in an appropriate grounded cable gland, at the point of entry with the front panel level pot so that the signals are free of into the industrial steel enclosure. If this is not possible, chassis noise and ripple, so a clear, easily read signal is displayed. ground screw terminals are provided on the G123-817-006. Ensure that the level is not so high as to distort the waveform. Exposed wires should be kept to a minimum length. Connect Select other frequencies with the frequency select switches to the screens at both ends of the cable to chassis ground. see if a minimum phase difference can be achieved. Select the frequency that gives a minimum phase difference. Be aware 4 Power supply that there is an adjustment on the circuit card that reduces the ...

- Page 3 5.3 Secondary phase difference the oscillator is not over loaded. Set to 20mA if using the 4-20mA signal output. The G123-817-006 circuit uses the primary signal to synchronously detect the secondary signal. Phase differences 6 Withdrawing the circuit card between these signals can cause minor errors and so there is the facility on the circuit card to null phase differences. from its case Withdraw the circuit card from its case and connect a dual ...

-

Page 4: Specifications

AS4251.1 emission Signal 0V Front panel Output span trimpots: Output zero Internet Data Oscillator level For a detailed Data Sheet and the latest version of this Full scale sensitivity: Min: 0.15 V/ V Application Note please refer to the Moog website Max: 0.9 V/ V www.moog.com/dinmodules Industrial Controls Division. Moog Inc., East Aurora, NY 14052-0018. Telephone: 716/687-4954. Fax: 716/655-1803. Toll Free 1-800-272-MOOG. Moog GmbH. Germany. Telephone: 07031-622-0. Fax: 07031-622-100. Moog Sarl. France. Telephone: 01 45 60 70 00. Fax: 01 45 60 70 01. Moog Australia Pty. Ltd. Telephone: 03 9561 6044. Fax: 03 9562 0246. Moog pursues a policy of continuous development and reserves the right to alter designs and specifications without prior notice. Information contained herein is for guidance only and does not form part of a contract. Australia: Melbourne, Sydney, Brisbane Austria: Vienna Brazil: S ao Paulo Denmark: Birkerød England: Tewkesbury Finland: Espoo France: Rungis Germany: Böblingen, Dusseldorf ...

Need help?

Do you have a question about the G123-817-006 and is the answer not in the manual?

Questions and answers