Table of Contents

Advertisement

Instructions for installation and operation

english

This manual contains important information and should be made available to all personnel who operate and/or maintain this product.

Carefully read this manual before attempting to operate or perform maintenance on this equipment.

www.i compressorpartners.com

Advertisement

Table of Contents

Summary of Contents for ICP iDRY

- Page 1 Instructions for installation and operation english This manual contains important information and should be made available to all personnel who operate and/or maintain this product. Carefully read this manual before attempting to operate or perform maintenance on this equipment. www.i compressorpartners.com...

-

Page 3: Table Of Contents

7.4 Contoller Outputs ................................16 7.5 Controller Settings ................................16 7.6 Service Rest Button ................................18 7.8 Power Requirements ................................18 8. MAINTENANCE AND SERVICE ................................19 8.1 Routine Maintenance ................................... 19 iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) - Page 4 10.2 Spare Parts ....................................27 11. DISMANTLING OF THE DRYER ................................28 12. ELECTRICAL WIRING DIAGRAM ................................ 29 13. GENERAL DESCRIPTION OF PARTS ..............................29 For technical product support please use website www.i compressorpartners.com iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A)

-

Page 5: Safety And System Precautions

Any change to the machine or to the standard operating parameters (see page 5), if not previously verified and authorized by the manufacturer, in addition to creating a potentially dangerous situation, will void the warranty. Don’t use water to extinguish fire on the dryer or in the surrounding area. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 6: Inspection And Installation

The installer and/or end user is responsible for the correct installation of the dryer in order to prevent excessive noise exposure in the work environment. The installer and/or end user is responsible to install proper safety signs at the installation site. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) - Page 7 We recommend using METPOINT® instrumentation to ensure accurate measurements. 7. All piping must be adequately supported and at least of equal size to the dryer connections. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A)

-

Page 8: Filters Mounted With Bypass

5.0 Micron (Grade G) Filtration Receiver Tank iPUR 1.0 Micron (Grade F) Filtration iDRY iDHLBe Desiccant Dryer with iPUR Pre and Post-filtration Dry Air Outlet Condensate Drainage Points for iMAT Optimal installation is with moderately sized receivers at the inlet and outlet side of the dryer. This allows for the additional free cooling and moisture collection and more consistent dryer inlet flow provided by an upstream receiver, while providing the most reliable shop air supply due to the downstream receiver. -

Page 9: Technical Specifications And General Function

SCFM is defined as the volume of free air in cubic feet per minute measured at 14.7 psia (1.013 bar) at 68 °F (20 °C) temperature with 0% relative humidity (0 WVP). iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 10: Correction Factors

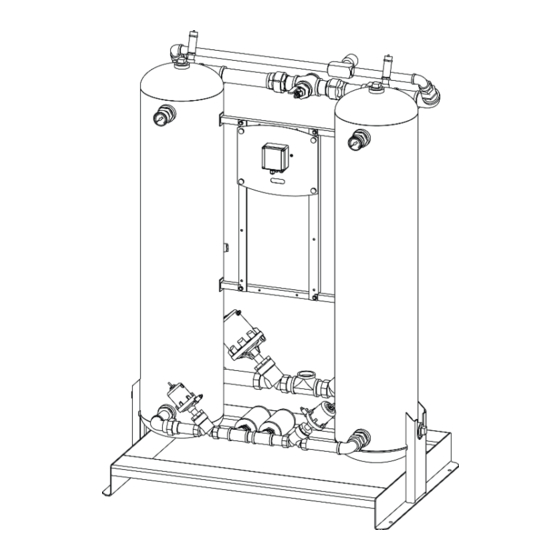

250 General Function The iDRY iDHLBe heatless desiccant dyer series are fitted with two pressure vessels, positioned parallel to one another and filled with adsorption material (⅛” activated alumina as standard). While the compressed air is dried in one tower, the saturated desiccant is regenerated in the second. -

Page 11: Flow Diagram

Purge Exhaust Valve (Normally Closed) Solenoid Block Exhaust Silencer Pilot Air Filter and Regulator Outlet Check Valves Vessel Pressure Gauge Pressure Relief Valve Pre-filter with Float Drain Purge Control Valve Post-filter with Manual Drain iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 12: Cycle Operation

The sum of step 4-5 + 6 equals a half cycle time. At the end, the cycle starts up again from step 1-2. NOTE: The cycles are symmetrical therefore 1-2=4-5 and 3=6 iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 13: Purge Valve Adjustment

100 psig 110 psig 115 psig iDRY 80 iDRY 100 iDRY 120 iDRY 160 iDRY 200 iDRY 250 iDRY 300 iDRY 400 iDRY 500 iDRY 800 Consult a factory representative for more information. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 14: Start-Up

Dispose of the condensate in a manner compliant with all local, state and Federal rules and regulations. We highly recommend the installation of either a QWIK-PURE® or ÖWAMAT® oil-water separator at the final collection point for all condensate discharge lines within the facility (i.e. from the main header). iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 15: Start-Up Procedures

At the first start-up or start-up after a long inactivity period or following maintenance shutdowns, we recommend operating the dryer at a reduced nominal flow of 50% during the first two days. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 16: General Operation

IMPORTANT! Always remove all pressure and disconnect all power before servicing the dryer. To restart the dryer, follow the start-up procedure in Section 5. START-UP iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 17: Controller Information And Operation

Controller Inputs The controller and housing provide three M12 and two M16 glands on for its input / output connection lines. For input, the connections are: Power cable Compressor-synchronization signal iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 18: Contoller Outputs

One DIP switch used for future expansion One DIP switch aligns the controller with the compressor sync One DIP switch used for future expansion Below is a picture of the DIP switch control interface: iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) - Page 19 Purge Air Time 4.0 minutes (1, 1, 0) Re-Pressure Build-Up 60 seconds (0, 0) Expansion OFF (0) Compressor Sync ON (1) Expansion OFF (0) (1) (1) (0) (0) (0) (0) (1) (0) iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A)

-

Page 20: Service Rest Button

The optional iMAT on the pre-filter at the dryer inlet is supplied according to the power voltage indicated in the order; verify its compatibility with the information given on the type plate. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 21: Maintenance And Service

3,000 operating hours per year. In all cases, the lifetime of desiccant material is heavily dependent on the quality and temperature of the inlet air and ensuring that scheduled maintenance is consistently carried out. Verify operation of the dryer iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 22: Maintenance And Service Intervals

The fuses can break if there are any problems with the dryer. In which case, only a certified technician can replace the fuse, but only after solving the problem that caused the malfunction first. Refer to Section 9, ‘TROUBLESHOOTING GUIDE’. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 23: Desiccant Replacement

5. Disassemble the valve for cleaning or repair. Service kits are available for all valves (see page 30). 6. Reassemble the valve and ensure that all O-rings, gaskets and components have reassembled or replaced accordingly. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 24: Troubleshooting Guide

Purge setting or clog, full open purge valve to clean out and then set according to table xx Purge Valve See Purge valve troubleshooting Inlet Valve See Inlet Valve Failure troubleshooting iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) - Page 25 Restriction SERVICEABLE ONLY BY QUALIFIED TECHNICIAN Damaged Seal Drain Application Overloaded with water, check pre-filter and upstream bulk water separator Electrical Check electrical connections iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A)

- Page 26 Ensure system temperature or fire has not occurred Solenoid Electrical Ensure connections and signal are adequate Pneumatic Ensure pilot supply is good and valve is clean Defective Replace with new iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A)

-

Page 27: Maintenance And Spare Parts

If you need to replace any other parts, please contact your local distributor or ICP Technical Service Department at www.icompressorpartners.com for assistance. - Page 28 2” Service Seal Kit 4027902 2½” Service Seal Kit 4027903 Desiccant Adsorption Material ⅛” Activated Alumina (total weight in lbs. per dryer) 4027023 150 150 230 230 340 340 480 625 795 940 iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A)

-

Page 29: Spare Parts

Replacement Tower Screen on request NOTE: When inquiring about any other part always indicate the data listed on the identification plate. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 30: Dismantling Of The Dryer

The adsorption material and the filter cartridge will contain droplets of lubrication oil. Do not dispose of these materials in the environment. All local Governmental laws and regulations must be followed in disposing of the above listed materials. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) -

Page 31: Electrical Wiring Diagram

All hard wired connections, including the power connections during installation are made to this device. Electric Solenoid – An electromechanical device used for controlling the flow of liquid or gas. iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) - Page 33 Independent Compressor Partners, LLC P.O. Box 206 Jeffersonville, IN 47131 www.i compressorpartners.com Subject to technical changes without prior notice; errors not excluded. www.i compressorpartners.com iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A)

Need help?

Do you have a question about the iDRY and is the answer not in the manual?

Questions and answers