Summary of Contents for Velocity SU-matic

- Page 1 May 2018 ONLY FOR OKUMA OKUMA INSTRUCTION MANUAL A Complete Lineup of In-Stock Lathe Tooling for Okuma Two Year Warranty...

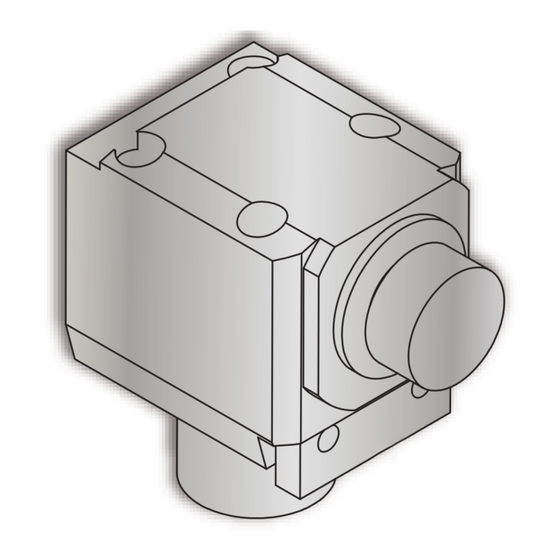

- Page 2 VELOCITY/SU-MATIC INSTRUCTION MANUAL VELOCITY / SU-matic Tooling Velocity Tooling is designed, engineered, and manufactured in Switzerland and Italy by SU-matic - a worldwide leader in tooling technology. SU-matic is the only lathe tooling manufacturer that focuses almost exclusively on Okuma tooling.

- Page 3 VELOCITY/SU-MATIC INSTRUCTION MANUAL VELOCITY / SU-matic LB2000M, LB3000M, LB4000M, LU3000M, LU4000M, MULTUS U3000, MULTUS U4000, LT3000 Driven Tool Installation Please consult the Okuma Operation & Maintenance Manual prior to mounting tools. LB-Series M-turret, LU-Series M-turret, MULTUS U-Series, and LT3000 driven tools use a front reference plate that is precision ground at the factory to align the tool output to the Z-axis.

- Page 4 VELOCITY/SU-MATIC INSTRUCTION MANUAL VELOCITY / SU-matic LB2000M, LB3000M, LB4000M, LU3000M, LU4000M, MULTUS U3000, MULTUS U4000, LT3000 Driven Tool Installation 1) Loosen the bolt on the back mounting plate on the tool. 2) Place the tool in the turret station two positions above the...

- Page 5 4) If minor adjustments are required, fasten the Velocity LT2000 VAF Alignment Fixture to the front or back of the tool as shown on the following page.

- Page 6 VELOCITY/SU-MATIC INSTRUCTION MANUAL VELOCITY / SU-matic LT2000 Tool Installation LT2000 VAF Alignment Fixture Fasten LT2000 VAF Alignment fixture VAF LT2000 to tool using these two screws. Alignment Fixture V E L O C I T Y P R O D U C T S . C O M Make any necessary tool alignment adjustments using these two screws.

- Page 7 VELOCITY/SU-MATIC INSTRUCTION MANUAL VELOCITY / SU-matic LT2000 Tool Installation LT2000 VAF Alignment Fixture V E L O C I T Y P R O D U C T S . C O M www.velocityproducts.com 256-258-5549 sales@velocityproducts.com...

- Page 8 VELOCITY/SU-MATIC INSTRUCTION MANUAL VELOCITY / SU-matic Coolant Tool Instructions All VELOCITY / SU-matic internal coolant tools require 30 absolute*. Cross/Radial coolant through tools cannot be run dry! Operating cross/radial coolant through tools without coolant will quickly damage tool seals and bearings*.

- Page 9 VELOCITY/SU-MATIC INSTRUCTION MANUAL VELOCITY / SU-matic Boring Bar Holders VELOCITY / SU-matic boring bar holders are shipped with coolant through plates installed. Extra nozzle plugs are included with the tool. If the tool is to be run with internal coolant only,...

- Page 10 VELOCITY/SU-MATIC INSTRUCTION MANUAL VELOCITY / SU-matic Adjustable Tool Special Instructions Please consult the Okuma Operation & Maintenance Manual prior to mounting tools. When an adjustable tool is used for milling, the maximum cutter diameter is 1/2 the maximum drill diameter for the tool.

- Page 11 VELOCITY/SU-MATIC INSTRUCTION MANUAL VELOCITY / SU-matic Capto Tools VELOCITY / SU-matic Capto live tools use a SU-matic designed, sealed draw tube mechanism. All VELOCITY / SU-matic Capto tools are internal coolant When installing a Capto cutting unit: 2) Push down hard on the torque wrench to make sure the hex drive is fully engaged in the hex socket.

- Page 12 TOOLING ® VELOCITY / SU-matic Capto Tools VELOCITY / SU-matic Capto tools use a Sandvik Capto clamping unit installed in the "Right" orientation as standard. If the "Left" orientation is required, the tool holder can be ordered in advance with "Left" orientation, or the clamping unit can be easily rotated by using a Sandvik CC-ET-01extracting tool (C4) and a C4-WDT-02 withdrawal tool.

- Page 13 VELOCITY/SU-MATIC CAPTO TOOLING ® VELOCITY / SU-matic Capto Tools The example below shows a main/sub spindle Capto OD holder. The orientation of the Capto clamping units can be adjusted so that the Capto cutting units are optimized for chip removal, insert maintenance, or uniformity of cutting units as shown on the next page.

- Page 14 VELOCITY/SU-MATIC CAPTO TOOLING ® VELOCITY / SU-matic Capto Tools The examples below show the options available on an Okuma LT2000 twin turret, main/sub spindle lathe for the orientation of the Capto clamping units on the tool holders, and also the choices available for the Capto cutting units.

- Page 15 VELOCITY/SU-MATIC CAPTO TOOLING ® VELOCITY / SU-matic Capto Tools If the Capto clamping unit needs to be rotated, the proper extracting tool and withdrawal tool must be used. Capto Size Withdrawal Tool Extracting Tool Extracting Tool C3-WDT-01M CC-ET-01 C4-WDT-02 Withdrawal...

- Page 16 350 Electronics Blvd, Huntsville, AL 35824 256-258-5549 www.velocityproducts.com sales@velocityproducts.com *Warranty voided if internal coolant tools are used without coolant and coolant filtration. Exceeding specified maximum cutting tool sizes voids warranty. © Velocity Products Specifications subject to change without notice SU-matic Instructions 5.2018...

Need help?

Do you have a question about the SU-matic and is the answer not in the manual?

Questions and answers