Summary of Contents for CNCroom MB3

- Page 1 MachBob3 (MB3) Owner’s manual Doc E1.3R2 (3/31/2019) for PCB V1.3 www.CNCRoom.com Page 1...

-

Page 2: Table Of Contents

Specification and Features ............................. 4 Precaution ..................................5 Quick Reference ................................6 MB3 Layout ................................... 7 ESS and MB3 piggyback ..............................8 MB3 Connection Diagram .............................. 9 Hardware ..................................10 Connecting the ESS to Your PC ............................10 Power Supply ..................................12 Axis Connection X, Y, Z, A, B, C ............................ - Page 3 Mach4 own configuration ............................... 43 Mach4 Keyboard config ..............................52 Appendix I MB3 Specifications ............................. 53 Appendix II MB3 Board Dimensions ..........................53 Appendix III Safety circuit options ..........................54 Safety Circuit 1 ..................................54 Safety Circuit 2 ..................................55 Safety Circuit 3 ..................................

-

Page 4: Introduction

While these things will help us achieve a better result, using a control board designed for industrial applications can be more important. MachBob3 (MB3) is designed for industrial application and specifically to work with the Ethernet Smooth Stepper (ESS) which is an excellent motion control board designed to be used with... -

Page 5: Precaution

This allows ESS to be mounted on MB3 directly without any ribbon cables. This makes the ESS easier to install and reduces the number of contact points, signals trace distance, inductance and resistance between ESS and MB3 board. As a result, all signals are less likely to be affected by noise and distortion. -

Page 6: Quick Reference

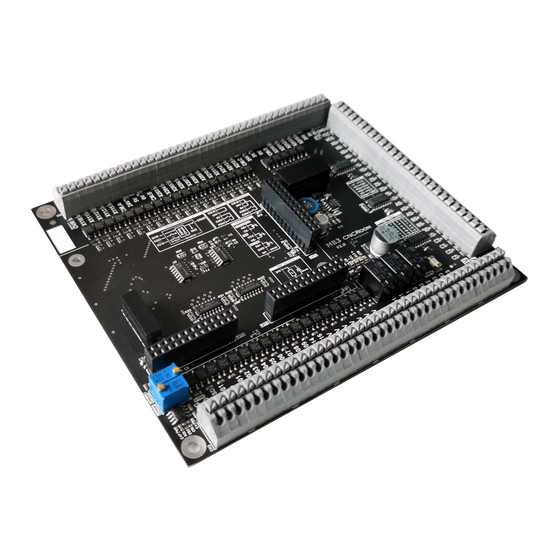

Table 1, Ports and Pins Reference Tables Quick Reference is a summary for the experienced users. Figure 1 is a shrinkage view of MB3 board. It shows the connection of inputs & outputs, power supply, analog output for the VFD and axis signals. -

Page 7: Mb3 Layout

MB3 Layout Figure 2, MB3 Board Layout 18-26 AWG 8–9mm www.CNCRoom.com Page 7... -

Page 8: Ess And Mb3 Piggyback

ESS and MB3 piggyback The ESS receives its 5Vdc power from the MB3 when all three jumpers of ESS are closed, which is the default setting. But you may need to change the jumpers do so before you install. This eliminates the need for an external 5Vdc supply. -

Page 9: Mb3 Connection Diagram

MB3 Connection Diagram Figure 4, Connection Diagram Figure 5, SCU utility successfully connected to the ESS. The SCU software utility helps the user to configure Windows PC to communicate with ESS www.CNCRoom.com Page 9 easily. Below is the link to SCU tutorial video. -

Page 10: Hardware

ESS and your PC. (A switch should be fine since it only operates in the lower 3 layers of the TCP/IP stack, but why add extra www.CNCRoom.com Page 10... - Page 11 You are on your own if you wish to mix the Internet with your CNC data. However, if you wish to change the IP address of the ESS, you may do so with the Configurator Utility. www.CNCRoom.com Page 11...

-

Page 12: Power Supply

Configurator Utility. Power Supply The MB3 needs only a single 24Vdc power supply to operate the board. Figure 7, shows power supply input terminals for 0V and 24V. The 24V, 3A power supply is recommended for general usage. -

Page 13: Axis Connection X, Y, Z, A, B, C

Figure 8 (b) Single end sink connection is used if the exist connection system follows this fashion. Figure 8 (c) Single end source connection is used if the exist connection system follows this fashion. This connection is similar to computer parallel port. www.CNCRoom.com Page 13... -

Page 14: Inputs

Placing terminals or ground lugs close to the MB3 makes for neater wiring to land shields and 0 or 5/24Vdc. The neater your wiring the easier to work with or add to. You should also consider the whole wiring scheme before wiring as you do not want to continually cross wires as this makes for a rats nest. -

Page 15: Input Type

On the left side is NPN input type which connects a switch between input X203 and 0V. On the right side is PNP input type which connects a switch between input X203 and power source 24V or 5V. www.CNCRoom.com Page 15... - Page 16 Figure 12 shows the 4 different methods to connect a switch with external power supply. These connections are totally isolated from any part of the MB3 circuit. The external circuits, for instance, could be the fault output of a VFD drive or plasma cutting system, where rough interference noise appears on the device.

-

Page 17: Sensors

5V SB Open 24V PNP output sensor CM.A brown X110 black,white OMRON EE-SX blue 5V SB Close 5V NPN output sensor Figure 15, Sensor connections Figure 15 shows the way to make connection with standard industrial sensors. www.CNCRoom.com Page 17... -

Page 18: Mpg / Encoder

5V NPN MPG/Encoder Figure 16, MPG/Encoder connection circuit MB3 board allows us to make a connection to low voltage devices. In this case, Figure 16 a 5V MPG device. It is similar to most encoders. Some encoders can do both source and sink. -

Page 19: Relays

Figure 19, connecting various loads to a “Y” output Relays The MB3 comes with three relays; those are K1, K2 and K3. All relays provide NO or NC contacts. The K1, K2 also provides an “OFF Delay” feature. To activate this feature the user needs to follow the instructions as set out on page 24 , topic [*4]. -

Page 20: Analog

At off s tate or 0% i t gi ves a weak negative voltage 9.50 9.602 1.07 to ens ure s pindle is turned off. 10.00 10.050 100% 0.50 Thi s graph is tested on Mach4. Figure 22, 0-10V Analog output characteristic www.CNCRoom.com Page 20... -

Page 21: Small Adjustment

Small Adjustment Figure 23, Analog output adjustment POT Even though the MB3 board has been fully tested and calibrated before shipping. The suitable analog output may be slightly different from the actual with any VFD. There is a multi-turn POT (Potentiometer) that allows us to gradually shift the whole range of actual-line up or down over command-line by mV unit as appears in Figure 23. -

Page 22: Ossd Output And Safety Circuit

OK signal to the next device. However, if there is an error feeding in, MB3 will send out a “Not OK” signal by de- energizing the OSSD output and the external safety circuit will cut power and stop the hazard. -

Page 23: Modification

Modification Solder Bridges The MB3 has a number of places where the user can conduct modifications. Instead of using pin jumpers, solder bridges have been implemented to save cost and space. The user needs to solder or de-solder these bridges to achieve their purpose. -

Page 24: [*2]. Safety Circuit Inputs

This can happen after the control signal or the main power is cut from its drive. Solder the bridge at K1 to enable an off delay of 440 ms, or at K2 for 660 ms. Figure 29, Off time delay Solder Bridge for K1 and K2 www.CNCRoom.com Page 24... -

Page 25: [*5]. Input Sub Common

Normally, K3 Relay is associated with output Y101. However, you can select K3 as an output relay of CP (charge pump) signal or Y317. Please be careful of this 3 way bridge selection. Make sure that you bridge only one position at a time. www.CNCRoom.com Page 25 Figure 32, K3 Pin select solder bridge. -

Page 26: [*8]. Analog Pin Select

Figure 33, PWM analog output solder bridge [*9]. Isolated Outputs Normally, MB3 provides high current transistor outputs. However, these outputs are slow, yet share common ground with other parts of the circuit board. In some circumstances, the user may need faster output or perhaps isolated output to interface with external device such as digital inputs of VFD which high voltage or noise interference running around them. -

Page 27: [*10]. Free Terminals

Software The user can obtain up to date software, plugins and tutorials from the following links. http://warp9td.com/index.php/sw http://www.youtube.com/channel/UCpg3EROtW8xA_KzrFHgn4ZQ The user also can obtain the MB3 pre configuration file from the product link below. https://www.cncroom.com/interface-cards/mb3 https://www.cncroom.com/interface-cards/ess-mb3 Mach3 Configuration The user can obtain the pre configuration XML file and copy it to their system. - Page 28 After downloading and extracting the pre configuration profile. You will find MB3.xml that needs to be copied and pasted into C:\Mach3 which is shown in picture below. Run Mach3 Loader and choose MB3 profile. Figure 36, Copy and Paste the MB3 pre-configuration file Figure 37, Mach3’s first screen...

-

Page 29: Menu Config > Ports And Pins

Menu Config > Ports and Pins Figure 38, Mach3 Ports and Pins dialog Figure 39, Motor output tab www.CNCRoom.com Page 29... - Page 30 Specify values as shown in the picture. Figure 40, Mach3 Input tab Only Estop signal is configured, but the rest of the inputs the user needs to set suitable values. www.CNCRoom.com Page 30...

- Page 31 Figure 41, Mach3 Output tab The user needs to set suitable values. www.CNCRoom.com Page 31...

-

Page 32: Menu Config > Motor Tuning

Figure 42, Mach3 Spindle tab Menu Config > Motor Tuning Figure 43, Mach3 Motor tuning dialog www.CNCRoom.com Page 32... - Page 33 Spindle Tuning and Spindle speed need to be set to get analog output 0-10V for entire spindle speed range. The value 10000 rpm is recommended during adjust analog output. But Actual speed will be used instead after finishing setup. www.CNCRoom.com Page 33...

-

Page 34: Menu Plugin Control > Main Config

Menu PlugIn Control > Main Config: Figure 46, ESS General Configuration Menu PlugIn Control > Spindle, THC & Laser Config: Figure 47, Spindle, THC and Laser Configuration www.CNCRoom.com Page 34... -

Page 35: Mach4 Configuration

Mach4 Configuration The user can obtain the pre configuration profile from the CNCRoom product page. However, there are some values that need to be set to suit the user’s individual system. After downloading and extracting the pre configuration profile. You will find a folder named MB3, copy and paste this folder into C:\Mach4Hobby\Profiles as shown in picture below. -

Page 36: Setting Up New Profile

Setting up new profile The pictures below show the sequence of making new profile for Mach4. Figure 49, Configure menu and step sequence Figure 50, Entry to ESS and Keyboard configuration www.CNCRoom.com Page 36... -

Page 37: Ess Configuration

Before we can see sub menu [2] and [3], we need enable them in next dialog which shown in Figure 49, Configure menu and step sequence ESS configuration Figure 51, ESS IP address and buffer size www.CNCRoom.com Page 37... - Page 38 Figure 52, Motor command mode Figure 53, Spindle Setup www.CNCRoom.com Page 38...

- Page 39 Figure 54, Pins Config and Alias Names Figure 55, Pins Config and Alias Names (continue 1) www.CNCRoom.com Page 39...

- Page 40 Figure 56, Pin Alias Names (continue 2) Figure 57, Input Signals Mapping www.CNCRoom.com Page 40...

- Page 41 Figure 58, Input Signals Mapping (continue 1) Figure 59, Output Signals Mapping The user must set each output active correctly otherwise that output will stay on constantly. www.CNCRoom.com Page 41...

- Page 42 Figure 60, Output Signals Mapping (continue 1) Figure 61, Output Signals Mapping (continue 2) www.CNCRoom.com Page 42...

-

Page 43: Mach4 Own Configuration

Figure 62, Homing, depends on the user’s choice Figure 63, Backlash, all default value Mach4 own configuration www.CNCRoom.com Page 43... - Page 44 Figure 64, Mach4 General Configuration Figure 65, Mach4 Plugins enabled www.CNCRoom.com Page 44...

- Page 45 Figure 66, Mach4 Motors profiles Figure 67, Mach4 Axis Mapping www.CNCRoom.com Page 45...

- Page 46 Figure 68, Mach4 Homing and Soft Limits Figure 69, Mach4 Input Signals www.CNCRoom.com Page 46...

- Page 47 Figure 70, Mach4 Input Signals (continue 1) Figure 71, Mach4 Input Signals (continue 2) www.CNCRoom.com Page 47...

- Page 48 Figure 72, Mach4 Output Signals Figure 73, Mach4 Output Signals (continue 1) www.CNCRoom.com Page 48...

- Page 49 Figure 74, Mach4 Output Signals (continue 2) Figure 75, Mach4 MPGs www.CNCRoom.com Page 49...

- Page 50 Figure 77, Mach4 Spindle The value in MaxRPM column for each range or gear number 0-15 is referenced to 10V. In this case, 10000 RPM is preferred for analog output tuning. Since it reflects to 0-10V while we enter www.CNCRoom.com Page 50...

- Page 51 MDI such as S10000 for 10V, S6000 for 6V, S3500 for 3.5V. The below is formula for 0-10V. Voltage = (Requested RPM / MaxRPM) * 10 Figure 78, Mach4 Tool Path Colors www.CNCRoom.com Page 51...

-

Page 52: Mach4 Keyboard Config

Figure 79, Mach4’s first screen Mach4 Keyboard config Figure 80, Mach4 Keyboard Mapping www.CNCRoom.com Page 52... -

Page 53: Appendix I Mb3 Specifications

Inputs voltage level 5/24Vdc Inputs response X1xx, X2xx 14.37khz / 69.58us / 862,200 index rpm* Inputs response X3xx 28.5khz / 35.08us / 1,710,000 index rpm* Ambient operating temperature 0-40°C *Tested on Mach4 Appendix II MB3 Board Dimensions www.CNCRoom.com Page 53... -

Page 54: Appendix Iii Safety Circuit Options

Please always seek professional advice from a qualified electrician or electrical engineer in your country of residence before implementing any circuit that is presented in this manual. CNCRoom cannot be held responsible for any adverse outcome, which came about as a result of copying anything from this manual. -

Page 55: Safety Circuit 2

Estop button. However, in normal circumstance, the MB3 with an external circuit and connection to a computer should work well together. In some drive connections you may need to implement the use of timer relays to handle an “Under Voltage”... -

Page 56: Safety Circuit 3

Safety Circuit 3 Since the MB3 board supports an “Off-Delay” function for relay K1 and K2, it allows the user to create a timing sequence for devices that need to power up or power down independently at different times. In this circuit an AC line monitor for recognising a “Power-Out” or “Black-Out” condition has also been introduced. -

Page 57: Appendix Iv Figure And Table References

Figures Figure Number Page Number Figure 1, MB3 Overview Connection ....................... 6 Figure 2, MB3 Board Layout ........................7 Figure 3, ESS board installation 5Vdc ...................... 8 Figure 4, Connection Diagram ......................... 9 Figure 5, Youtube tutorial video for beginner..................10 Figure 6, Power supply connection ....................... - Page 58 Figure 33 Solder bridges for Isolated transistor outputs............... 26 Figure 34 solder bridges at terminal pin ....................27 Figure 35, Copy and Paste the MB3 pre-configuration file ..............28 Figure 36, Mach3’s first screen ......................28 Figure 37, Mach3 Ports and Pins dialog ....................29 Figure 38, Motor output tab ........................

- Page 59 Figure 68, Mach4 Input Signals ......................46 Figure 69, Mach4 Input Signals (continue 1) ..................47 Figure 70, Mach4 Input Signals (continue 2) ..................47 Figure 71, Mach4 Output Signals ......................48 Figure 72, Mach4 Output Signals (continue 1) ..................48 www.CNCRoom.com Page 59...

-

Page 60: Table

Figure 79, Mach4 Keyboard Mapping ....................52 Figure 80, Safety Circuit 1 ........................54 Figure 81, Safety Circuit 2 ........................55 Figure 82, Safety Circuit 3 ........................56 Table Table 1, Ports and Pins Reference Tables ....................6 www.CNCRoom.com Page 60...

Need help?

Do you have a question about the MB3 and is the answer not in the manual?

Questions and answers